Description

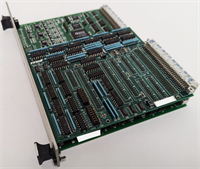

Key Technical Specifications (For Spare Part Verification)

- Part Number: D100644

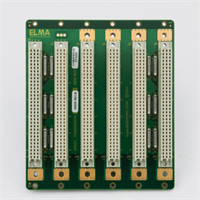

- Form Factor: DIN-rail mounted I/O module for Metso DNA racks

- Function Type: Likely a digital input, digital output, or analog I/O module (exact function requires verification via legacy manuals or label markings)

- I/O Channels: Typically 8–16 channels per module (varies by subtype)

- Electrical Interface:

- Digital: 24 V DC sink/source (depending on model)

- Analog: 4–20 mA or 0–10 V (if applicable)

- Communication: Proprietary Metso DNA backplane protocol

- Diagnostics: Basic LED indicators per channel (Power, OK, Fault)

- Redundancy: Supported in redundant DNA configurations (dual-module setups)

- Operating Environment: Industrial temperature range (typically 0°C to +60°C), IP20 protection

METSO D100644

System Role and Downtime Impact

The D100644 module serves as a critical link between field instrumentation and the Metso DNA distributed control system (DCS). In continuous-process industries like pulp mills or mineral processing plants, loss of I/O functionality can lead to:

- Inability to monitor critical equipment status (e.g., pump running, valve position)

- Failure to execute interlocks or safety sequences

- Degraded or failed regulatory control loops

- Automatic trip of production lines due to “signal loss” diagnostics

Because many legacy DNA systems lack full I/O redundancy, a single failed module can halt an entire process section. Recovery depends entirely on spare availability—making this component a high-priority obsolescence risk.

Reliability Analysis and Common Failure Modes

Despite rugged industrial design, the D100644 is prone to age-related issues:

- Optocoupler degradation (in digital modules): Leads to signal dropout or false triggering

- Analog front-end drift (if applicable): Causes measurement inaccuracies in 4–20 mA loops

- Connector or terminal block corrosion: Especially in humid or chemically aggressive environments

- Power supply capacitor aging: Results in unstable internal logic voltage

- Backplane contact fatigue: Thermal cycling causes intermittent communication with the controller

Preventive measures include:

- Regular functional testing during planned outages

- Thermographic scanning to detect abnormal heating

- Keeping firmware/hardware revision logs to ensure spare compatibility

- Storing verified spares in dry, ESD-safe conditions

METSO D100644

Lifecycle Status and Migration Strategy

Metso discontinued the DNA platform after its automation business was transferred to Valmet. Valmet no longer manufactures or supports legacy DNA I/O modules like the D100644. Official technical support is extremely limited, and replacement parts are only available through:

- Industrial surplus dealers (with no performance guarantee)

- Third-party repair services offering refurbished units

- Reverse-engineering firms providing functional equivalents

Short-term mitigation:

- Identify and label all D100644 modules in your system

- Acquire and functionally test 2–3 spares while still available

- Document wiring and configuration to accelerate replacement

Long-term strategic path:

Migrate from Metso DNA to a modern DCS platform such as:

- Valmet DNA Evolution (successor platform, partial backward compatibility)

- ABB Ability™ System 800xA

- Emerson DeltaV

- Rockwell PlantPAx

Migration typically involves:

- Replacing I/O cabinets with new hardware

- Rewiring field devices (often reusing existing cable infrastructure)

- Translating control logic and HMI graphics

- Recommissioning safety and regulatory loops

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: