Description

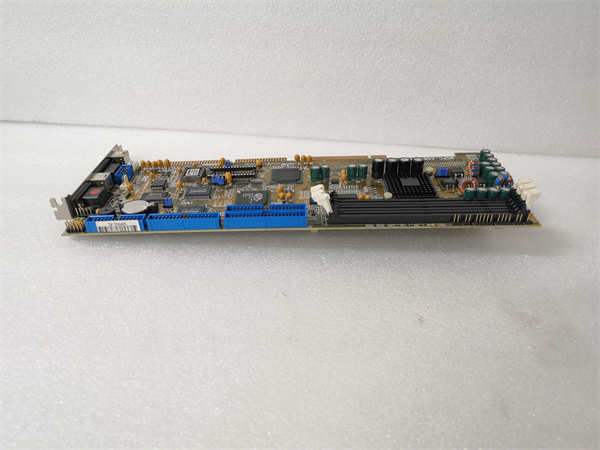

Key Technical Specifications (For Spare Part Verification)

- Product Model: MSPC-68866800

- Manufacturer: Macrotek (formerly active in industrial automation hardware; no longer supports this product line)

- System Integration: Typically deployed as standalone HMI or integrated with third-party control systems (e.g., ABB, Siemens, Rockwell) via serial or Ethernet

- Processor: Intel Celeron or Pentium-class (circa early 2000s), exact variant undocumented but typically <1 GHz

- Memory: 256–512 MB RAM (soldered or SO-DIMM, non-standard)

- Storage: 2.5″ IDE or CompactFlash-based hard drive (typically 2–10 GB)

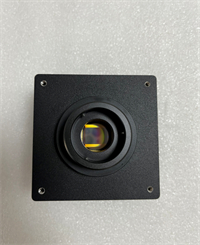

- Display: 15″ TFT LCD, SVGA (1024×768) or XGA resolution, resistive touch screen

- Operating System: Windows XP Embedded or Windows 2000 (license tied to original image)

- I/O Interfaces: RS-232/485 serial ports, 10/100 Mbps Ethernet, USB 1.1/2.0, PS/2

- Mounting: Panel-mount with IP65 front protection

- Power Supply: 24 V DC input (±10%), internal AC/DC converter not present

System Role and Downtime Impact

The Macrotek MSPC-68866800 functions as a local operator interface in aging industrial facilities—commonly found in power generation, water treatment, and manufacturing plants installed between 2000 and 2010. It runs proprietary or third-party SCADA/HMI software (e.g., RSView, WinCC Flexible, or custom VB6 applications) to display real-time process data, allow manual control of valves or motors, and log alarms. Unlike modern thin-client HMIs, this unit operates as a full standalone computer. If it fails—due to hard drive crash, backlight failure, or motherboard fault—the operator loses all local visibility and control capability for that station. In non-redundant setups, this often forces a controlled shutdown of the associated process unit until the HMI is restored. Recovery can take days if no pre-imaged spare is available, as reimaging requires matching legacy OS licenses and application binaries.

Reliability Analysis and Common Failure Modes

Due to its age and embedded design, the MSPC-68866800 exhibits several predictable failure patterns. The most frequent issue is hard drive failure, as early CompactFlash or mechanical drives exceed their write-cycle or operational lifespan. A second common failure is LCD backlight or inverter degradation, causing dim or flickering displays. Capacitor aging on the motherboard—particularly electrolytic capacitors in the power regulation circuit—leads to random reboots or failure to power on. Additionally, the resistive touch screen often suffers from calibration drift or dead zones after years of use.

Design weaknesses include non-standard internal components, lack of SSD support in original BIOS, and dependence on obsolete Windows licensing. Preventive maintenance should include: (1) cloning the system drive to a known-good spare; (2) storing a backup of the HMI project file and runtime license; (3) inspecting the display for uniform brightness; and (4) verifying touch calibration during routine outages.

Macrotek MSPC-68866800

Lifecycle Status and Migration Strategy

Macrotek discontinued industrial panel PCs years ago and no longer provides technical documentation, firmware, or repair services for the MSPC-68866800. The model is fully obsolete, with zero manufacturer support. Continuing to operate it poses cybersecurity risks (unpatched Windows XP) and escalating hardware failure probability.

As an interim measure, facilities can maintain cold spares with pre-cloned drives or retrofit the unit with a compatible third-party motherboard and SSD—but driver and OS compatibility is uncertain. The recommended long-term strategy is replacement with a modern, standards-based panel PC from vendors like Advantech, Beckhoff, or Siemens. This migration involves: (1) selecting a mechanically compatible replacement (same cutout size); (2) upgrading to Windows 10 IoT or Linux; (3) recompiling or replacing the HMI application using current tools (e.g., Ignition, WinCC OA); and (4) validating communication with the existing control system. While requiring engineering effort, this eliminates single-point hardware risk and restores secure, supported operation. For critical stations, deploying a temporary remote desktop solution (via secure gateway) can provide short-term operational continuity during transition planning.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: