Description

Key Technical Specifications (For Spare Parts Verification)

- Product Model: FLA6041

- Manufacturer: Laurence Scott (historically UK-based; brand now integrated into Regal Rexnord portfolio)

- Motor Type: Three-phase, AC induction, squirrel cage rotor

- Frame Size: IEC 160 or similar (verify via physical measurement or legacy drawings)

- Power Rating: Typically 7.5–15 kW (exact rating must be confirmed from nameplate or commissioning records)

- Voltage / Frequency: Commonly 400 V / 50 Hz or 460 V / 60 Hz (region-dependent)

- Enclosure: TEFC (Totally Enclosed Fan Cooled), IP55 protection

- Insulation Class: Usually Class F (155°C)

- Duty Cycle: Continuous (S1)

- Mounting: IM B3 (foot-mounted) or IM B5 (flange-mounted)—verify application

- Bearings: Standard deep-groove ball bearings (e.g., 6208 / 6309); lubrication type critical for maintenance

System Role and Downtime Impact

The FLA6041 motor typically serves as the prime mover in mid-duty industrial applications such as boiler feedwater pumps, cooling water circulation, or HVAC compressors. While seemingly a standard component, its integration into skid-mounted or custom-engineered systems often means that direct replacement requires matching not only electrical parameters but also shaft dimensions, mounting footprint, and coupling alignment. A sudden failure can cascade into plant-wide impacts—especially if the motor drives safety-related or continuous-process equipment. In older facilities, these motors may lack modern condition monitoring provisions (e.g., RTD sensors or vibration ports), delaying fault detection until catastrophic breakdown.

Reliability Analysis and Common Failure Modes

Motors of this era (commonly installed in the 1980s–1990s) remain in service due to robust cast iron construction and conservative design margins. However, they are now highly susceptible to age-related failures:

- Insulation degradation: Thermal cycling and moisture ingress lead to winding ground faults or phase-to-phase shorts.

- Bearing fatigue: Lack of regreasing access or use of incompatible grease causes premature wear, resulting in high vibration and shaft misalignment.

- Shaft corrosion or scoring: Especially in humid or washdown environments, compromising seal and coupling integrity.

- Terminal box deterioration: Cracked housings or corroded terminals create fire or arc-flash hazards.

Design limitations include absence of built-in thermal protection (PTC/RTD) in many versions and reliance on external overload relays, which may not detect single-phasing or gradual insulation decay.

Recommended preventive actions:

- Perform annual insulation resistance (IR) and polarization index (PI) tests using a megohmmeter.

- Monitor bearing temperature and vibration trends via handheld or fixed sensors.

- Verify alignment and coupling condition during every maintenance window.

- Maintain accurate records of full-load amps (FLA) and no-load current for baseline comparison.

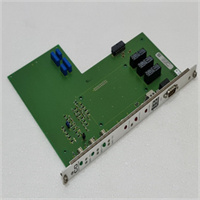

LAURENCE SCOTT FLA6041

Lifecycle Status and Migration Strategy

Laurence Scott discontinued the FLA series decades ago, and the brand has undergone multiple ownership changes (now under Regal Rexnord). Original technical support and spare parts (e.g., replacement end shields or stators) are unavailable. Continuing to operate these motors carries increasing risk of unplanned failure, with long lead times for custom rewinds or replacements.

Interim strategies include:

- Commissioning a like-for-like rewind from a certified motor repair shop (ensure VPI impregnation and Class F insulation).

- Creating a “clone” motor by reverse-engineering key mechanical dimensions for future drop-in replacement.

- Installing external protection relays with phase-loss, thermal modeling, and ground-fault detection to extend service life.

For permanent resolution, replace with a modern IE3 or IE4 efficiency motor from Regal Rexnord’s current portfolio (e.g., Marlin Electric or GE Motors lines), ensuring compatibility with:

- Existing base or flange dimensions (may require adapter plates)

- Shaft height, diameter, and keyway specs

- Electrical characteristics (kW, RPM, torque curve)

Note that while newer motors offer energy savings, differences in starting torque or inertia may require review of driven equipment dynamics. A full mechanical and electrical audit is recommended before replacement in critical service.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: