Description

Key Technical Specifications (For Spare Verification)

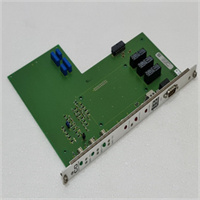

- Product Model: SMPCONT-A3B

- Manufacturer: KOKUSAI Electric Corporation

- System Family: KOKUSAI dry etch, plasma etch, or CVD equipment (e.g., ELEVA series)

- Function: RF matching network control logic and driver interface

- Interface Signals: Analog/digital feedback from voltage/current sensors; PWM or relay outputs to motor-driven capacitors

- Power Supply: Typically ±12 VDC and +5 VDC (verify via system schematics)

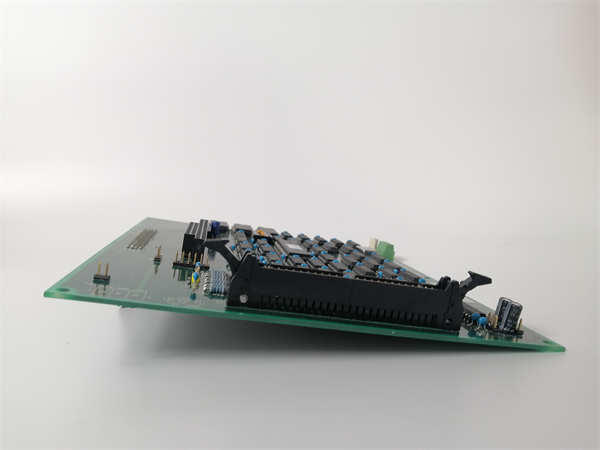

- Connectors: Proprietary multi-pin headers (e.g., JAE or Hirose types common in 1990s–2000s Japanese tools)

- Form Factor: Custom PCB, usually mounted inside RF generator or matching network enclosure

- Firmware/Configuration: May contain DIP switches, jumpers, or mask-programmed microcontrollers

- Compatibility: Specific to certain tool models and RF generator versions (e.g., MKS, Comet, or ENI units integrated with KOKUSAI platforms)

System Role and Downtime Impact

The SMPCONT-A3B is a mission-critical subsystem within KOKUSAI semiconductor processing equipment, responsible for dynamically adjusting the impedance match between the RF generator and the plasma chamber. Proper operation ensures maximum power delivery, stable plasma ignition, and consistent etch/deposition rates. If this board fails or malfunctions, the matching network may stall at an incorrect position, causing reflected power spikes, process drift, or automatic tool aborts. In high-utilization wafer fabs, such a failure can halt an entire process module for hours or days—especially since the board is deeply embedded in proprietary architectures with no standardized replacement. Given its role in yield-sensitive operations, even intermittent faults can lead to scrap wafers, requalification costs, and missed delivery schedules.

Reliability Analysis and Common Failure Points

Due to its operating environment—exposed to electromagnetic interference, thermal cycling, and high-voltage transients—the SMPCONT-A3B exhibits several recurring failure modes:

- Electrolytic capacitor degradation: Onboard filtering capacitors dry out over time, leading to unstable regulation of analog sensing circuits and erratic tuning behavior.

- Op-amp or comparator drift: Precision analog components used in V/I detection circuits lose calibration, causing incorrect match-point calculations.

- Relay or MOSFET driver failure: Output stages that drive motor coils or solid-state switches degrade from repeated switching under load, resulting in stuck capacitors.

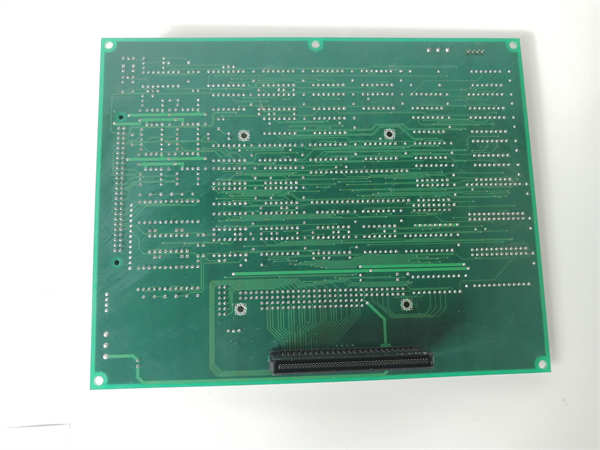

- Connector or trace corrosion: Humidity or chemical exposure in fab environments accelerates oxidation on edge connectors and PCB traces, creating intermittent opens.

A key design limitation is the lack of self-diagnostics or communication logging—most faults manifest only as process alarms (e.g., “High Reflected Power”) without clear root-cause indication. To mitigate risk, maintenance teams should:

- Perform periodic inspection of solder joints and capacitors under magnification

- Monitor reflected power trends during preventive maintenance runs

- Clean connectors with contact-safe solvents and apply conformal coating if permitted

- Maintain detailed records of board serial numbers and associated tool performance history

KOKUSAI SMPCONT-A3B

Lifecycle Status and Migration Strategy

KOKUSAI Electric has long discontinued the SMPCONT-A3B, with no direct replacement offered under current Screen Holdings ownership. Official technical documentation is scarce, and factory repair services are unavailable. Continued use carries severe operational risk: near-zero new supply, no calibration support, and increasing vulnerability to cascading failures in aging tools.

As a temporary measure, some fabs rely on third-party electronics refurbishers who perform component-level rework (e.g., capacitor replacement and burn-in testing). However, functional validation requires access to the original tool—a significant logistical hurdle.

Long-term, the only sustainable path is tool-level modernization. Options include:

- Retrofitting the RF subsystem with a modern, standalone matching network (e.g., from Advanced Energy or Horiba) that includes built-in digital control and Ethernet diagnostics

- Replacing the entire process chamber with a newer platform compatible with current-generation controls

- Implementing external monitoring (e.g., VI probes with AI-based anomaly detection) to predict matching failures before they cause process excursions

While capital-intensive, such upgrades restore reliability, improve process window control, and eliminate dependency on unobtainable legacy electronics—critical for extending the life of strategic but aging semiconductor assets.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: