Description

Technical Specifications (For Spare Parts Verification)

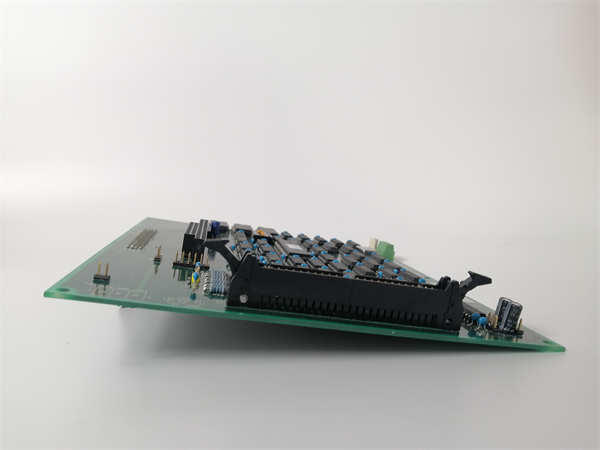

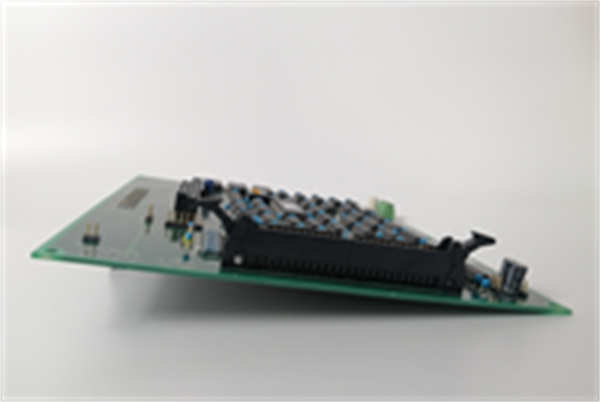

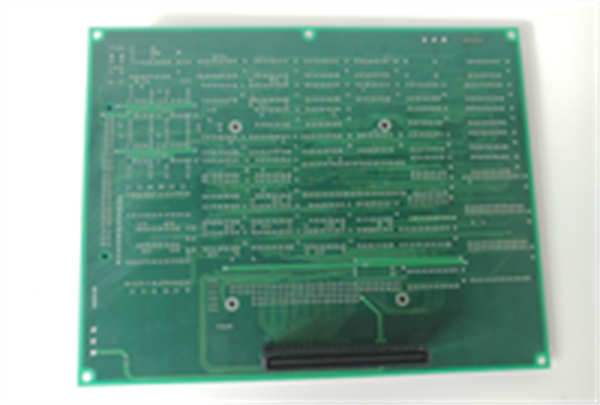

- Product Model: SMPCONT-A3B

- Manufacturer: KOKUSAI Electric Corporation

- Associated System: KOKUSAI DCS Series Vertical Diffusion Furnaces (e.g., DCS-320, DCS-630)

- Board Type: Multi-layer PCB with custom ASICs and discrete analog circuitry

- Primary Interface: Proprietary backplane connector to I/O and power modules

- Control Functions: Temperature profile execution, MFC (mass flow controller) coordination, door actuator logic

- Power Input: +5 VDC, +12 VDC, -12 VDC (via system backplane)

- Communication: RS-485 to host supervisory computer (KNET protocol)

- Diagnostic Indicators: LED status array for heater, gas, vacuum, and fault states

- Physical Dimensions: Approx. 280 mm × 220 mm (standard Eurocard form factor)

System Role and Downtime Impact

The SMPCONT-A3B serves as the central nervous system of KOKUSAI’s older batch diffusion furnaces, which are still operational in mature-node semiconductor fabs (e.g., power devices, MEMS, analog ICs). It directly governs critical thermal processes such as oxidation, diffusion, and annealing by coordinating heaters, gas valves, and pressure controls according to pre-programmed recipes. A failure of this board—whether due to power surge, component aging, or firmware corruption—results in an immediate and complete halt of the furnace chamber operation. Since these systems often run 24/7 with high-value wafer lots inside, unplanned downtime can lead to batch loss, cross-contamination, or extended line stoppages. In many facilities, this single board represents a single point of failure with no hot-spare redundancy, making its availability a top-tier maintenance concern.

Reliability Analysis and Common Failure Modes

The SMPCONT-A3B is prone to several age-related failure mechanisms common in early-2000s industrial electronics. The most prevalent issue is electrolytic capacitor degradation, particularly in power regulation circuits, leading to voltage instability and erratic behavior (e.g., spontaneous resets or heater overshoot). A second frequent failure involves corrosion or cold solder joints on high-current traces connected to relay drivers, exacerbated by thermal cycling during repeated furnace ramps. Additionally, the onboard battery-backed SRAM (used for recipe storage) often fails after 10–15 years, causing loss of calibration data or boot errors.

A key design vulnerability is the lack of isolation between analog sensor inputs and digital logic, making the board sensitive to ground loops or EMI from nearby RF generators or plasma tools. Furthermore, the proprietary firmware cannot be re-flashed without original KOKUSAI service tools, which are no longer distributed.

Preventive maintenance should focus on:

- Annual infrared thermography of the control cabinet to detect hot spots on the board

- Visual inspection for bulging capacitors or discolored PCB areas near power regulators

- Verification of backup battery voltage (typically 3.6 V lithium); replace if <3.2 V

- Ensuring clean, stable 24 VDC auxiliary power to the furnace control section to avoid backplane ripple

SMPCONT-A3B KOKUSAI

Lifecycle Status and Migration Strategy

KOKUSAI (now under SCREEN) ceased support for the SMPCONT-A3B platform over a decade ago, with no official repair or replacement program. Continuing to operate equipment with this controller carries escalating risks: zero factory warranty, no access to firmware updates, and increasing difficulty in diagnosing faults due to lost engineering knowledge.

For fabs committed to extending tool life, two interim approaches exist:

- Board-Level Refurbishment: Partner with specialized third-party labs capable of component-level repair, capacitor replacement, and functional burn-in testing.

- Cold-Spare Stocking: Secure multiple verified working units now while inventory remains available.

The strategic migration path involves either:

- Retrofitting with a modern PLC-based control system (e.g., using Siemens S7-1500 or Rockwell CompactLogix), which requires re-engineering I/O wiring, rewriting process recipes, and re-validating thermal profiles—a significant but one-time capital project.

- Tool replacement with SCREEN’s latest batch or single-wafer platforms (e.g., SCREEN SD series), which offer superior process control, SECS/GEM compliance, and cloud-enabled diagnostics.

Any migration must include a full safety reassessment (per SEMI S2/S8) and recalibration of temperature uniformity across the wafer boat. Given the high cost of wafer scrap, proactive planning for SMPCONT-A3B obsolescence is not optional—it is a production continuity imperative.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: