Description

Key Technical Specifications (For Spare Parts Verification)

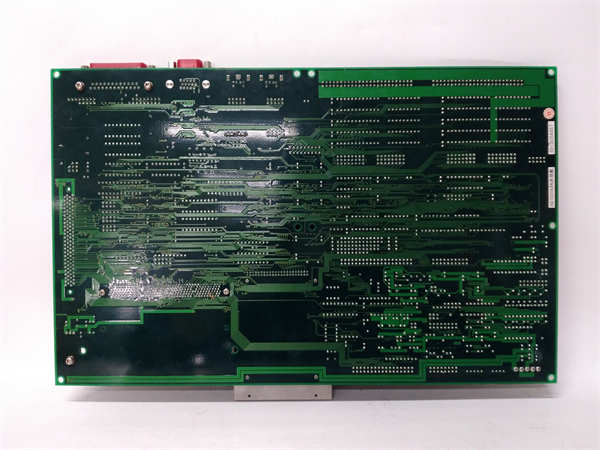

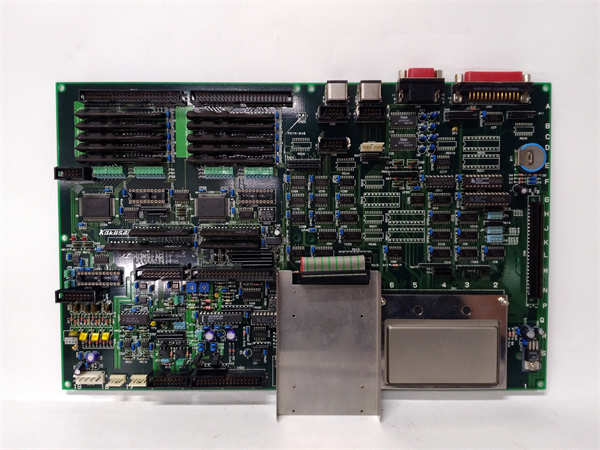

- Product Model: KOMS-A2 CXP-544A

- Manufacturer: Kokusai Electric Co., Ltd.

- System Platform: KOMS-A2 furnace control system (used in vertical diffusion furnaces)

- Function: Likely digital I/O, analog output, or communication interface between main controller and field devices (e.g., MFCs, heaters, valves)

- Form Factor: Proprietary PCB with edge connector or DIN-rail mounting

- Power Requirements: Typically +5 VDC / ±15 VDC from system backplane

- I/O Type: May include relay outputs, thermocouple inputs, or RS-485 serial links

- Connectors: Proprietary multi-pin headers or screw terminals

- Firmware/Configuration: May require DIP switches or onboard EEPROM matching original system revision

- Markings: Silkscreen includes “CXP-544A”, revision code (e.g., “Rev 2”), and Kokusai logo

System Role and Downtime Impact

The CXP-544A module typically resides within the main control cabinet of a Kokusai vertical diffusion furnace, interfacing between the central sequencer and critical process actuators such as heater power controllers, purge valves, or pressure sensors. If this board fails—due to signal dropout, output short, or communication loss—the furnace may abort the current batch, enter a safe hold state, or, in worst-case scenarios, fail to respond to over-temperature conditions. In high-utilization fabs, even a 4–8 hour downtime event can result in significant yield loss and scheduling disruption across multiple layers of production. Because these tools often run proprietary control logic with minimal documentation, troubleshooting is slow, and replacement without a verified spare can extend outages to days or weeks.

Reliability Analysis and Common Failure Modes

Most units in service have exceeded 20 years of operational life, often under continuous thermal cycling and electrical stress.

Common failure modes include:

- Relay contact welding or coil burnout: Onboard electromechanical relays degrade after repeated switching, causing stuck-open or stuck-closed states in gas or power circuits.

- Thermocouple input amplifier drift: Analog front-end components age, leading to inaccurate temperature readings and process deviations.

- EEPROM corruption: Loss of calibration or configuration data due to battery-backed memory failure.

- PCB delamination or trace cracking: Repeated heating/cooling cycles cause mechanical fatigue, especially near high-current traces or connectors.

Design weaknesses include:

- Use of through-hole components with limited conformal coating, increasing vulnerability to humidity and chemical vapors in cleanroom exhaust areas;

- Lack of self-diagnostics—failures are often only detected when a process step fails;

- Dependence on obsolete ASICs or custom logic chips with no second-source alternatives.

Preventive maintenance recommendations:

- Perform quarterly functional tests using simulated I/O signals;

- Inspect for discoloration, burnt smell, or capacitor leakage during routine tool PMs;

- Maintain at least one fully tested spare per tool model, stored in dry nitrogen if possible;

- Document jumper settings and firmware revisions for rapid recovery.

-

KOKUSAI KOMS-A2 CXP-544A

Lifecycle Status and Migration Strategy

Kokusai Electric (now under SCREEN Semiconductor Solutions) no longer supports the KOMS-A2 platform. The CXP-544A has no official replacement, and factory repair services were discontinued years ago. Continued use carries significant operational and quality risk, particularly in regulated semiconductor manufacturing where process repeatability is critical.

Interim mitigation options include:

- Engaging specialized electronics refurbishment firms for board-level rework (relay replacement, reballing, etc.);

- Sourcing units only from vendors who provide full functional validation on a matching KOMS-A2 test bench;

- Implementing external monitoring (e.g., PLC watchdog on key outputs) to detect latent failures.

Long-term, the recommended path is tool retrofit or control system modernization. Many fabs have successfully migrated legacy Kokusai furnaces to open architectures using:

- Industrial PCs running real-time control software;

- Standard I/O modules (e.g., Beckhoff, National Instruments) replacing proprietary boards;

- OPC UA servers for integration into modern MES and APC systems.

While retrofit requires engineering investment, it eliminates recurring obsolescence crises, improves diagnostic visibility, and extends the useful life of otherwise sound mechanical systems. For tools still in production, initiating a feasibility study for control modernization should be prioritized alongside aggressive spare-part risk management.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: