Description

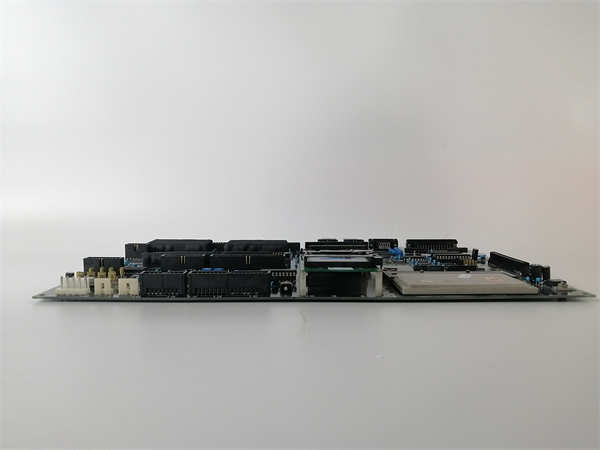

Key Technical Specifications (For Spare Parts Verification)

- Product Model: KOMS-A2

- Manufacturer: Kokusai Electric

- Host System: CXP-544A Process Controller (part of CXP series for vertical furnaces)

- Function: Multi-channel analog output board (typically 8–16 channels)

- Output Type: ±10 VDC or 4–20 mA (configurable per channel, depending on firmware revision)

- Resolution: 12-bit or 14-bit DAC (Digital-to-Analog Converter)

- Isolation: Channel-to-channel and system ground isolation (opto or transformer-based)

- Connector Type: High-density DIN or Hirose-style backplane connector (specific to CXP rack)

- Firmware Dependency: Requires matching boot ROM and system software version in CXP-544A CPU

- Physical Form: Proprietary PCB size with edge connector; typically housed in metal EMI shield

- Diagnostic Indicators: Minimal (usually only power LED; no per-channel status)

System Role and Downtime Impact

The KOMS-A2 module resides within the CXP-544A controller chassis, serving as the primary analog output interface between the central processor and field devices in high-temperature diffusion or oxidation processes. It directly drives MFCs for gas flow, thyristor power controllers for heaters, and pneumatic valves for pressure regulation.

If this module fails—due to signal drift, complete channel loss, or communication dropout—the CXP system may:

- Enter fault state and halt processing mid-batch

- Deliver incorrect gas ratios or temperature profiles, leading to wafer yield loss

- Trigger false interlocks or fail to respond to recipe commands

In a 200mm or legacy 300mm fab still operating CXP-based tools, a KOMS-A2 failure can result in >24 hours of unplanned downtime due to lack of spares, complex requalification requirements, and dependency on aging documentation. The module is not redundant in standard configurations, making it a single point of failure.

Reliability Analysis and Common Failure Modes

Despite industrial-grade design, KOMS-A2 modules exhibit predictable degradation after 15–25 years of service in cleanroom environments:

- DAC drift: Aging of reference voltage sources or DAC chips causes output offset, leading to inconsistent process results even if the module appears “functional.”

- Capacitor degradation: Electrolytic capacitors on power rails dry out, causing ripple-induced noise or intermittent resets.

- Backplane connector corrosion: Gold plating wear or flux residue leads to high contact resistance, manifesting as sporadic channel dropouts.

- Firmware mismatch: Replacement boards with incompatible ROM versions cause system boot failures or erratic behavior.

- Thermal stress cracks: Repeated thermal cycling in furnace-adjacent cabinets fatigues solder joints, especially around high-power components.

Design weaknesses include lack of per-channel diagnostics, no hot-swap capability, and dependence on obsolete surface-mount components that are no longer commercially available.

For preventive maintenance, technicians should:

- Perform quarterly loop calibration checks using precision multimeters or calibrators

- Monitor process recipe repeatability as an indirect indicator of analog output health

- Store spare modules in static-safe, climate-controlled environments with desiccant

- Maintain a known-good firmware image for rapid recovery

KOKUSAI CXP-544A KOMS-A2

Lifecycle Status and Migration Strategy

Kokusai Electric discontinued the CXP series—including the CXP-544A and all KOMS modules—following its acquisition by SCREEN Holdings. Official support ended over a decade ago, and no repair services are offered. Continuing to operate with KOMS-A2 introduces severe operational risk:

- No access to factory-tested replacements

- Inability to meet SEMI E10 or E164 equipment reliability standards

- Growing difficulty sourcing compatible test equipment or schematics

As an interim measure, facilities may:

- Source boards only from trusted surplus vendors who provide full functional test reports under simulated load

- Implement board-level repair through specialized third parties (with component-level traceability)

- Cross-calibrate multiple spares to establish baseline performance envelopes

For strategic migration, SCREEN/Kokusai’s recommended path is replacement of the entire CXP-544A system with the Kokusai Triaxys® or SCREEN SEDA platform, which offer modern digital I/O, Ethernet-based control, and SECS/GEM compliance. This requires full recipe requalification and mechanical integration but eliminates obsolescence exposure.

Given its role in critical thermal processes, the obsolescence of the KOMS-A2 represents a high-priority risk for fabs relying on legacy Kokusai tools. A formal risk mitigation plan—including sparing, monitoring, and capital upgrade scheduling—is essential to sustain production continuity and yield stability.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: