Description

Key Technical Specifications (For Spare Parts Verification)

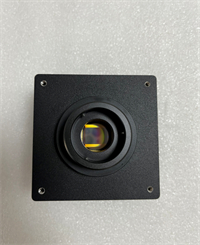

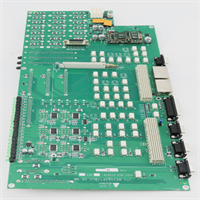

- Product Model: CXP-544A KOMS-A2

- Manufacturer: KOKUSAI Electric Corporation (now SCREEN)

- System Family: CXP Series Vertical Diffusion/Oxidation Furnaces with KOMS control architecture

- Module Type: Likely digital I/O or analog interface board (exact function varies by system configuration)

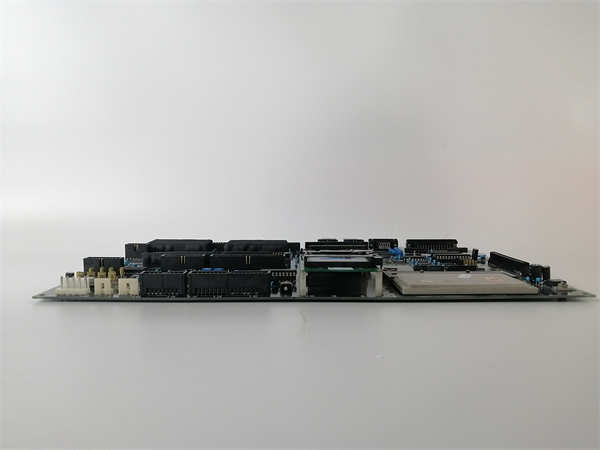

- Mounting: Proprietary backplane slot within KOMS control rack

- Power Supply: Low-voltage DC via backplane (typically +5 V / ±12 V)

- Communication: Proprietary KOMS bus protocol; may support RS-485 or parallel signaling to terminal boards

- Diagnostic Indicators: Onboard LEDs for power, activity, and fault status (if equipped)

- Firmware/Revision: Hard-coded logic; revision “A2” must match system requirements

- Environmental Rating: Designed for cleanroom operation (non-condensing, low particulate)

System Role and Downtime Impact

The CXP-544A KOMS-A2 is an embedded control module within KOKUSAI’s legacy thermal processing equipment, widely deployed in 200mm and early 300mm semiconductor fabs for oxidation, diffusion, and annealing processes. It acts as a critical link between the central KOMS CPU and field devices such as mass flow controllers, thermocouples, pressure sensors, and pneumatic actuators. A malfunction—whether due to component failure, communication loss, or firmware mismatch—can cause process aborts, temperature excursions, or activation of emergency purge sequences. In high-utilization fabs, even a short furnace downtime can result in wafer scrap, missed delivery schedules, and costly recovery procedures, especially if the tool runs critical layers like gate oxide or well drive-in.

Reliability Analysis and Common Failure Modes

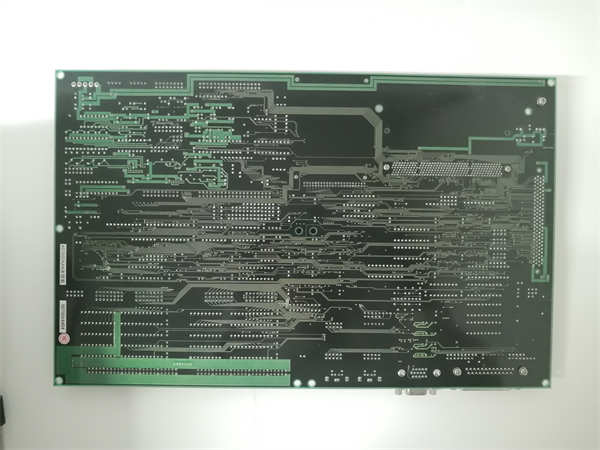

As a proprietary industrial electronics module from the late 1990s to early 2000s, the CXP-544A exhibits typical aging vulnerabilities:

- Electrolytic capacitor degradation on power regulation circuits, leading to voltage instability and intermittent resets.

- CMOS latch-up or ESD damage on I/O driver ICs, often triggered by ground potential differences during maintenance or utility fluctuations.

- Backplane connector fretting corrosion, causing signal dropouts—particularly problematic in modules handling analog sensor inputs.

- Memory bit errors in onboard SRAM or PROM (if present), exacerbated by long-term exposure to elevated fab ambient temperatures.

A significant design constraint is the lack of standardized diagnostics; fault isolation typically requires swapping with a known-good unit or using legacy KOMS engineering software that may no longer run on modern PCs. Additionally, the module contains no user-serviceable components, and its proprietary form factor prevents direct third-party replacement.

Preventive maintenance should include: periodic inspection of adjacent modules for heat discoloration, verifying grounding continuity of the control rack, ensuring stable facility power with surge suppression, and maintaining validated backups of the entire KOMS application.

KOKUSAI CXP-544A KOMS-A2

Lifecycle Status and Migration Strategy

KOKUSAI (now under SCREEN) has long since discontinued the CXP platform and its associated KOMS control hardware. Official support is restricted to extended service contracts at premium cost, and no new CXP-544A modules are manufactured. Continued operation relies entirely on dwindling spare pools, increasing the risk of prolonged outages.

Interim strategies include securing tested spares from retired tools, engaging specialized third-party repair firms capable of board-level rework (e.g., capacitor replacement, reballing connectors), and implementing external monitoring to detect early signs of module degradation.

For long-term viability, SCREEN recommends migration to modern furnace platforms such as the SEDA series, which feature standardized industrial controllers (e.g., based on SECS/GEM, EtherNet/IP), enhanced process repeatability, and full cybersecurity compliance. While migration requires capital investment and requalification of thermal recipes, it eliminates dependency on obsolete, single-source hardware like the CXP-544A KOMS-A2 and aligns the toolset with current industry automation standards.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: