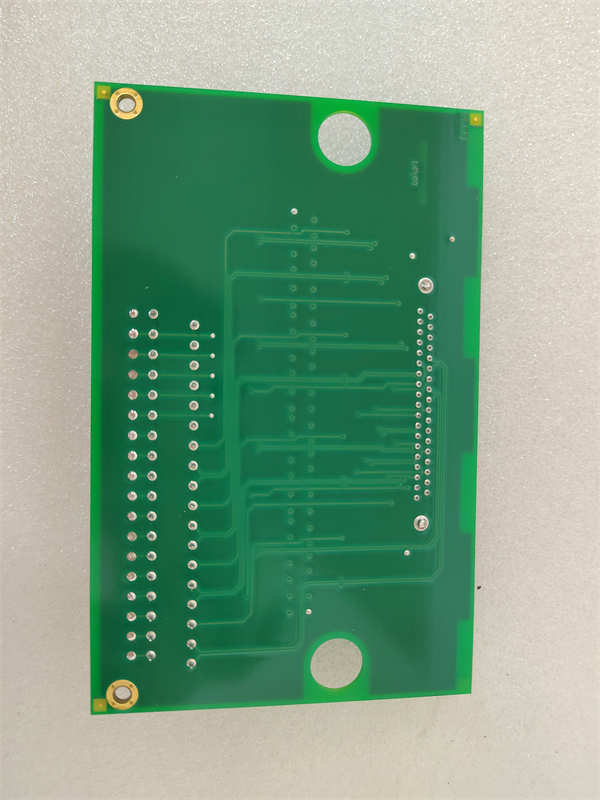

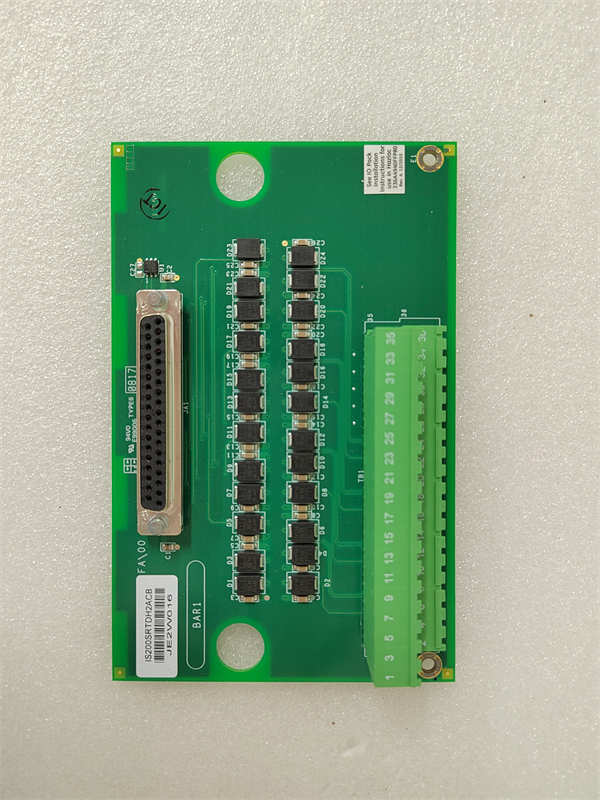

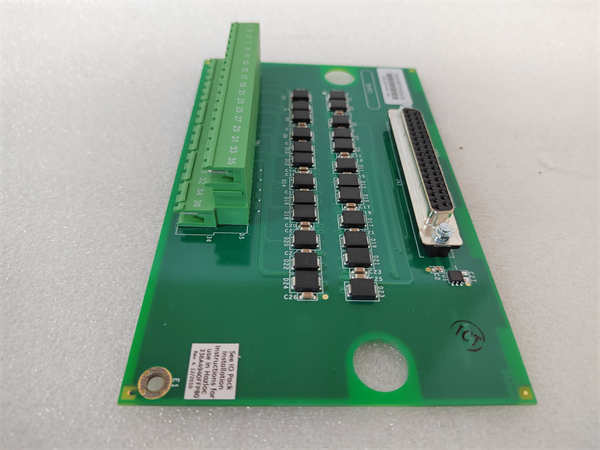

Description

Key Technical Specifications (For Spare Parts Verification)

- Product Model: IS200SRTDH2ACB

- Manufacturer: GE Power (now GE Vernova)

- System Platform: Mark VI Turbine Control System (Simplex or Dual redundant architecture)

- Input Channels: 6 differential inputs for magnetic pickups or proximity probes

- Signal Type: AC voltage from speed sensors (typically 1–100 Vpp, frequency up to 5 kHz)

- Output Interface: Connects to Mark VI terminal board (e.g., TBSM or TBQP series) via ribbon cable

- Power Supply: +5 VDC and ±15 VDC from backplane

- Operating Temperature: 0°C to +60°C

- Diagnostic Capability: Channel fault indication via front-panel LEDs and system-level diagnostics in ToolboxST

- Mounting: DIN-rail or rack-mounted within turbine control enclosure

System Role and Downtime Impact

The IS200SRTDH2ACB is a mission-critical I/O module in the GE Mark VI control system, responsible for acquiring real-time rotational speed and phase angle data from turbine shaft sensors. This information is used by the control processors to manage startup ramps, load control, grid synchronization, and—most critically—the mechanical overspeed protection function. Unlike later TMR-based systems (Mark VIe), the Mark VI often uses dual or simplex configurations, making each SRTD module a single point of failure for speed signal integrity. A malfunctioning IS200SRTDH2ACB can cause false speed readings, leading to either an unnecessary turbine trip or, more dangerously, a failure to detect a genuine overspeed event. In utility-scale or combined-cycle plants, such a failure can result in forced outages lasting days and revenue losses exceeding $1 million per incident.

Reliability Analysis and Common Failure Modes

Although designed for industrial use, the IS200SRTDH2ACB is vulnerable to several age- and environment-related failure mechanisms due to its continuous operation in high-temperature, electrically noisy turbine enclosures:

- Electrolytic capacitor degradation: The analog signal conditioning circuitry relies on capacitors that dry out over time, causing signal attenuation, increased jitter, or complete channel failure. Units installed prior to 2012 are at elevated risk.

- Input protection diode failure: Repeated exposure to voltage spikes from sensor wiring faults or ground loops can damage transient suppression components, leading to erratic behavior or shorted inputs.

- Ribbon cable and connector wear: The flexible cable connecting the module to the terminal board is prone to fatigue from thermal cycling, resulting in intermittent contact or open circuits.

- PCB delamination and trace corrosion: Humidity ingress or chemical exposure in poorly sealed cabinets can corrode copper traces, especially near high-impedance nodes.

Recommended preventive maintenance actions include:

- Conducting annual signal waveform checks using an oscilloscope during planned outages.

- Verifying proper grounding of sensor shields and terminal blocks.

- Inspecting ribbon cables for cracks or discoloration.

- Storing spare modules in dry, temperature-controlled environments with periodic functional testing.

IS200SRTDH2ACB GE

Lifecycle Status and Migration Strategy

GE has officially discontinued the IS200SRTDH2ACB as part of its strategic shift toward the Mark VIe and Mark VIeS platforms. No new units are manufactured, and OEM repair services are no longer available. Continued operation with this module introduces significant operational and financial risk due to dwindling spare availability and rising costs in the secondary market.

Interim risk mitigation options:

- Procure only from vendors who perform full functional validation under simulated turbine signal conditions.

- Establish a “tested spare” inventory with documented burn-in and calibration records.

- Implement external signal monitoring to detect early signs of degradation (e.g., amplitude drop or waveform distortion).

Long-term migration path:

GE’s endorsed upgrade route is migration to the Mark VIe platform, which replaces the IS200SRTDH2ACB with the TMR-capable IS220PRTDH1BC or its successors. This transition requires:

- Replacement of the entire I/O subsystem, including terminal boards and cabling.

- Recalibration and re-commissioning of all speed and position sensors.

- Reconfiguration of control logic in the new application environment. While this represents a substantial capital investment, it restores access to OEM support, improves system reliability through redundancy, and aligns the asset with modern cybersecurity and remote monitoring standards. For facilities not yet ready for full replacement, disciplined spare management and proactive condition monitoring remain essential to mitigate unplanned downtime.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: