Description

Technical Specifications (For Spare Part Verification)

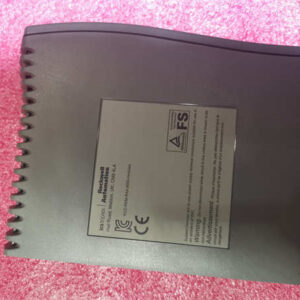

- Product Model: T9402

- Manufacturer: ICS Triplex

- System Family: Trusted™ TMR Safety Instrumented System (SIS)

- Input Channels: 16 isolated analog inputs (typically 4–20 mA or 1–5 VDC)

- Redundancy Architecture: Triple-redundant signal paths with internal voting (per Trusted TMR principles)

- Diagnostic Coverage: >99% (per IEC 61508/61511 for SIL 3 applications)

- Accuracy: ±0.1% of span (typical)

- Isolation: Channel-to-channel and channel-to-backplane isolation (>500 VAC)

- Backplane Interface: Proprietary Trusted chassis bus (requires compatible mainframe, e.g., T94xx series rack)

- LED Indicators: Power, OK, Fault, and channel status per group

- Operating Temperature: 0°C to +60°C

- Certification: Compliant with IEC 61508 SIL 3, API RP 14C, and ANSI/ISA 84.01

System Role and Downtime Impact

The ICS Triplex T9402 is a foundational component in Trusted TMR safety systems deployed in oil & gas offshore platforms, refineries, and chemical plants where functional safety is non-negotiable. It acquires critical process variables—such as reactor pressure, turbine vibration, or flare header temperature—and feeds them into the triple-redundant logic solver. The TMR architecture ensures that even if one or two internal channels fail, the system continues to operate safely or initiates a controlled shutdown. However, if a faulty T9402 is installed without proper validation, it may either fail dangerously (not trip when required) or fail safely (cause an unnecessary plant trip). In either case, the consequences are severe: environmental incidents, equipment damage, or multi-million-dollar production losses. Given its role in SIL 3 loops, the absence of a functionally verified spare represents a direct threat to process safety and operational continuity.

Reliability Analysis and Common Failure Modes

Despite its robust TMR design, the T9402 is subject to aging effects common in electronics operating continuously since the late 1990s to early 2000s. The most frequent failure mode is degradation of input signal conditioning circuits, particularly in channels exposed to sustained overcurrent or ground loops, leading to drift or complete loss of signal. Internal DC-DC converters that power the redundant channels can also degrade, causing intermittent faults that evade standard diagnostics. Additionally, electrolytic capacitors on the power and analog boards dry out after 15+ years, resulting in increased noise, reduced common-mode rejection, or unexpected module resets.

Key vulnerabilities include:

- Sensitivity to improper grounding practices in the field wiring

- Limited tolerance for sustained overvoltage beyond specified range

- Dependence on precise calibration—drift may not trigger a fault LED but can compromise safety margins

Preventive maintenance recommendations:

- Perform annual partial-stroke testing of associated final elements to validate full loop integrity

- Conduct module-level diagnostics using Trusted Workbench software to check channel health and voting status

- Inspect terminal blocks for corrosion, especially in marine or humid environments

- Maintain a calibrated spare under controlled storage conditions (low humidity, stable temperature)

ICS Triplex T9402

Lifecycle Status and Migration Strategy

ICS Triplex discontinued the T9402 as part of the broader phase-out of legacy Trusted hardware, with official support ending in the early 2010s. Schneider Electric now positions the Triconex Trident or Tricon CX platforms as the strategic successors. No new T9402 modules are manufactured, and existing inventory is restricted to decommissioned units or untested surplus—posing significant risk due to unknown service history.

As a temporary measure, operators may:

- Secure a small number of fully tested and calibrated spares from certified vendors

- Implement enhanced online monitoring of analog signal trends to detect early drift

- Enforce strict handling procedures (ESD protection, anti-static packaging) during storage and installation

For long-term compliance, migration to Triconex Trident is the recommended path. This involves:

- Replacing the entire Trusted mainframe with a Trident chassis

- Rewiring I/O to new terminal bases (though field cabling can often be reused via marshalling)

- Recompiling the application logic in Triconex Enhanced Development Environment (EDE)

- Revalidating all safety instrumented functions (SIFs) per IEC 61511

While capital-intensive, this migration restores access to factory support, modern cybersecurity features, and extended lifecycle assurance—critical for facilities operating under stringent regulatory regimes. A phased approach during turnarounds minimizes disruption while systematically eliminating obsolescence risk in high-integrity safety systems.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: