Description

Key Technical Specifications (For Spare Part Verification)

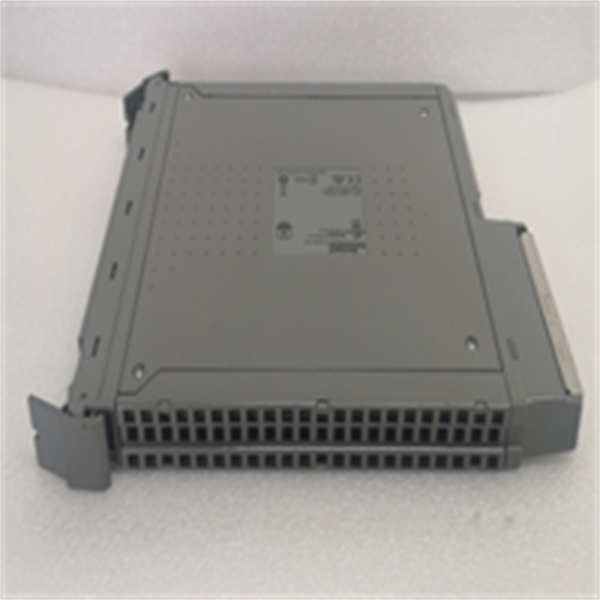

- Product Model: T8461C

- Manufacturer: ICS Triplex

- System Family: Trusted TMR safety system (Trusted® SIS platform)

- Module Type: TMR digital output (typically 24 V DC sourcing or relay contact)

- Channels: 8 independent output channels (configurable per application)

- Redundancy Architecture: Triple-modular redundant voting at channel level

- Diagnostic Coverage: >99% with continuous self-testing

- Power Requirement: Powered via backplane from TMR power supply modules

- Mounting: DIN rail within certified Trusted chassis (e.g., T8100 series)

- Certification: Compliant with IEC 61508 SIL 3, ANSI/ISA 84.01

- Connector Type: Front-pluggable terminal blocks or ribbon cable interface (varies by revision)

System Role and Downtime Impact

The T8461C is a foundational component in ICS Triplex Trusted safety systems, widely deployed in high-hazard industries such as oil & gas, petrochemicals, and power generation. It executes the final output stage of Safety Instrumented Functions (SIFs)—for example, de-energizing a solenoid to close an emergency shutdown valve or tripping a turbine. Operating under a triple-modular redundant (TMR) architecture, it ensures fail-safe operation even in the presence of single or dual hardware faults. Because it resides in certified safety loops, failure or unavailability of the T8461C can compromise the integrity of the entire SIF. In non-redundant or partially degraded configurations, a faulty module may prevent system reset after a trip or—worse—cause a dangerous undetected failure. Replacement delays due to part scarcity can extend plant outages or force operation in bypass mode, increasing regulatory and safety exposure.

Reliability Analysis and Common Failure Modes

Despite its robust TMR design, the T8461C is subject to aging effects after 15–25 years of service. The most frequent failure modes involve output driver circuits: MOSFET or relay wear-out from repeated switching, especially when driving inductive loads without proper snubbing. Internal diagnostic LEDs or status buffers may degrade, leading to false “healthy” indications. Connector corrosion on front terminals or backplane pins—accelerated by humidity or hydrogen sulfide in offshore/refinery environments—can cause intermittent channel faults that trigger spurious trips. Although rare, internal FPGA or voter logic corruption due to cosmic rays or voltage transients has been documented in legacy units lacking modern radiation hardening.

Preventive measures include regular proof testing per IEC 61511 requirements, thermal imaging of output terminals under load, inspection for discoloration or odor near output drivers, and verification of loop resistance to detect early wiring degradation. Modules should never be hot-swapped, as transient currents can damage the TMR voter circuitry.

ICS Triplex T8461C

Lifecycle Status and Migration Strategy

Schneider Electric (which acquired ICS Triplex) has formally declared the T8461C and the broader Trusted TMR product line obsolete. Manufacturing ceased years ago, and official repair, exchange, or calibration services are no longer available. New units are nonexistent; remaining stock consists of used or refurbished modules from decommissioned sites, often sold without traceable certification—posing compliance risks in regulated industries.

As a temporary measure, some operators maintain “golden spares” in climate-controlled storage and implement strict handling protocols. However, long-term strategy must focus on migration. Schneider recommends transitioning to the Triconex™ 3700 series (e.g., 3760 Digital Output Module), which offers backward compatibility in certain chassis and supports modern cybersecurity standards. Full migration typically involves replacing I/O modules, updating Tristation 1131 application logic for new hardware mappings, and re-validating all SIFs—a significant but necessary investment. For greenfield or major revamp projects, adoption of the latest Triconex eXpress or Quantum Safety platforms provides enhanced diagnostics, remote access, and lifecycle support aligned with current functional safety regulations. Continuing to operate on obsolete TMR hardware increases both operational risk and compliance liability.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: