Description

Key Technical Specifications (For Spare Part Verification)

- Product Model: 9100

- Manufacturer: ICS Triplex (Schneider Electric)

- System Family: TMR (Triple-Modular Redundant) Safety System

- Architecture: Triple-redundant voting logic with continuous self-diagnostics

- Safety Integrity Level: Certified to IEC 61508 SIL3 / ANSI/ISA S84.01

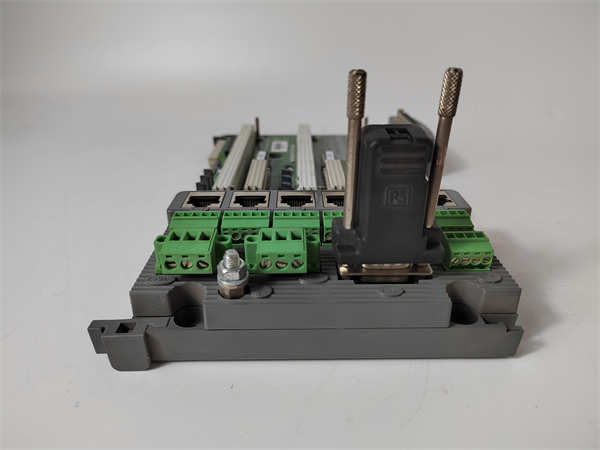

- Form Factor: Rack-mounted module for TMR chassis (typically 9000-series backplane)

- Communication Interfaces: Proprietary TMR bus for I/O and peer modules; optional serial or Ethernet for engineering

- Power Requirements: Redundant +5V DC from system power supplies

- Status Indicators: LEDs for OK, FAULT, VOTE, and module activity

- Configuration Storage: Battery-backed SRAM or flash (varies by revision)

System Role and Downtime Impact

The ICS Triplex 9100 functions as the central logic solver in a TMR safety instrumented system (SIS), where three independent processing lanes execute identical logic and vote on outputs to detect and mask faults. It is typically deployed in mission-critical applications such as emergency shutdown (ESD) in offshore platforms, boiler furnace protection, or compressor anti-surge control. Due to its role in enforcing safety interlocks, failure of this module—even in a triple-redundant setup—can degrade system redundancy or, in worst cases, trigger a spurious trip that halts production. If all three modules or the supporting infrastructure fail, the system may enter a safe state (e.g., full plant shutdown), resulting in significant financial and operational consequences. Because the TMR platform is no longer supported, recovery from failure is heavily dependent on the availability of verified spare modules.

Reliability Analysis and Common Failure Modes

Despite its robust fault-tolerant design, the 9100 module is vulnerable to age-related hardware degradation. The most prevalent failure mechanisms include battery depletion in modules that rely on SRAM for configuration retention—leading to program loss after power cycles—and capacitor aging in the internal power regulation circuitry, causing intermittent resets or communication faults. The proprietary TMR backplane connectors are also prone to oxidation over time, especially in humid or corrosive environments, which can disrupt synchronization between redundant lanes. Additionally, firmware corruption due to cosmic radiation or electrical noise—though rare—is harder to diagnose in legacy systems lacking modern diagnostic logs. Preventive maintenance should focus on regular verification of module diagnostics via Triplex Tools software (if available), inspection of battery health (where applicable), cleaning of backplane contacts, and ensuring stable, clean power delivery from redundant system supplies.

ICS TRIPLEX 9100

Lifecycle Status and Migration Strategy

Schneider Electric has officially discontinued the ICS Triplex TMR platform, including the 9100 controller, and no direct replacement exists within the current product portfolio. Continued use poses severe risks: spare parts are nearly unobtainable through official channels, third-party vendors offer unverified units with no warranty, and technical support is limited to archival documentation. As a short-term measure, facilities may maintain a stock of tested spares or engage specialized firms capable of board-level repair—but these are stopgap solutions. The recommended long-term strategy is migration to a modern safety platform such as Schneider’s Triconex Trident or Rockwell’s GuardLogix 5580 with SIL3 certification. This transition requires comprehensive revalidation of safety logic, re-engineering of I/O marshalling, and requalification of the entire safety loop—typically executed during major turnaround windows. While capital-intensive, migration eliminates obsolescence risk, improves cybersecurity compliance, and enables integration with digital operations platforms for predictive maintenance and remote diagnostics.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: