Description

Key Technical Specifications (For Spare Parts Verification)

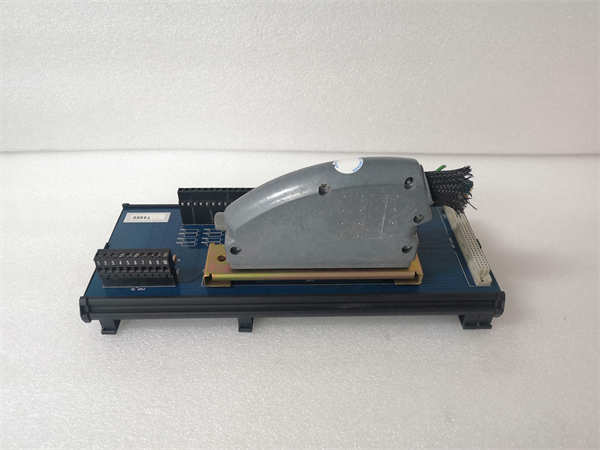

- Product Model: T8850

- Manufacturer: ICS (Integrated Control Systems)

- System Family: ICS Turbine Control System (commonly used in industrial gas turbines, steam turbines, and marine propulsion)

- Input Channels: Typically 16 differential analog inputs (exact count may vary by revision)

- Signal Types Supported: Thermocouples (J, K, T), RTDs (Pt100), and 4–20 mA current loops

- Input Isolation: Channel-to-channel and channel-to-backplane isolation (typically >500 VDC)

- Sampling Rate: ~100 ms per channel (system-dependent)

- Communication Interface: Proprietary parallel or serial backplane bus to ICS main processor (e.g., T8000 series CPU)

- Mounting: Pluggable card in ruggedized ICS chassis with conduction cooling

- Diagnostic Features: Open-circuit detection for RTDs/thermocouples; signal range alarms

- Operating Environment: Designed for high-vibration, high-temperature turbine skid environments (typically -20°C to +70°C ambient)

System Role and Downtime Impact

The T8850 serves as a foundational I/O module in legacy ICS turbine control systems widely deployed in cogeneration plants, offshore platforms, and naval vessels from the 1980s through early 2000s. It digitizes critical process variables—such as exhaust temperature, bearing vibration, lube oil pressure, and speed probe signals—and delivers them to the central controller for real-time regulation and protective shutdown logic. A failure in this module can result in multiple sensor channels going offline simultaneously. In a protection-configured system, this often triggers a “sensor fault” alarm that escalates to a controlled turbine trip to prevent mechanical damage. Given the age of these installations and the scarcity of engineering expertise, unplanned outages due to T8850 failure can extend for days or weeks, with significant operational and financial impact.

Reliability Analysis and Common Failure Modes

Despite robust military-grade construction, the T8850 is now well beyond its design life. Common failure mechanisms include:

- Analog front-end drift: Precision instrumentation amplifiers and cold-junction compensation circuits degrade over decades, causing offset or gain errors—especially in thermocouple channels.

- Connector and edge-finger corrosion: Repeated thermal cycling and exposure to humid or saline environments cause oxidation on backplane contacts, leading to intermittent communication or channel dropouts.

- Capacitor aging: Onboard tantalum and electrolytic capacitors lose capacitance or develop high ESR, destabilizing local voltage regulators and causing resets or noise.

- EPROM/bit rot: Older revisions storing calibration coefficients in EPROM may experience data corruption, resulting in nonsensical readings (e.g., negative temperatures).

Recommended preventive actions:

- Perform annual calibration verification using certified simulators for each sensor type

- Clean backplane slots and module edge connectors with contact enhancer during outages

- Monitor for correlated channel failures, which often indicate module-level (not sensor) issues

- Maintain at least one fully tested spare per turbine, ideally with matching firmware and calibration history

ICS T8850

Lifecycle Status and Migration Strategy

ICS was absorbed into Rolls-Royce’s controls division, which has long since discontinued support for the T8850 and related hardware. No new modules are available, and OEM repair services were terminated years ago. Continuing to operate this hardware carries substantial risk: spares are untraceable, diagnostic tools are obsolete, and replacement expertise is vanishing.

For facilities requiring continued operation, interim options include:

- Sourcing functionally tested units with full channel validation reports

- Engaging specialized third-party firms capable of board-level repair and recalibration

- Implementing external signal conditioners with redundant outputs to standard PLC analog inputs (as a last-resort workaround)

The strategic migration path is typically a full turbine control system upgrade. Common industry approaches include:

- Replacement with Rolls-Royce’s modern control platforms (e.g., for RR-powered turbines)

- Retrofit with third-party turbine control systems such as those from Woodward, Siemens (SPPA-T3000), or GE (Mark VIe)

- Integration into a hybrid architecture where ICS handles basic sequencing while a new safety PLC (e.g., Triconex, ABB AC 800PEC) manages protection functions

Such migrations require extensive re-engineering—including sensor rewiring, logic re-implementation, and regulatory recertification—but are increasingly necessary to ensure reliability, cybersecurity, and compliance with modern operational standards. A phased risk assessment based on asset criticality and outage cost should guide the transition timeline.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: