Description

Key Technical Specifications (For Spare Parts Verification)

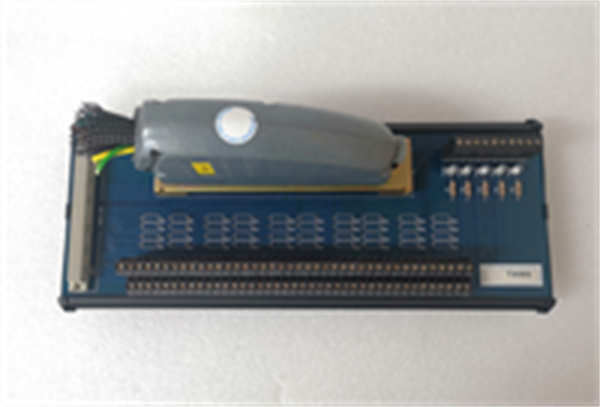

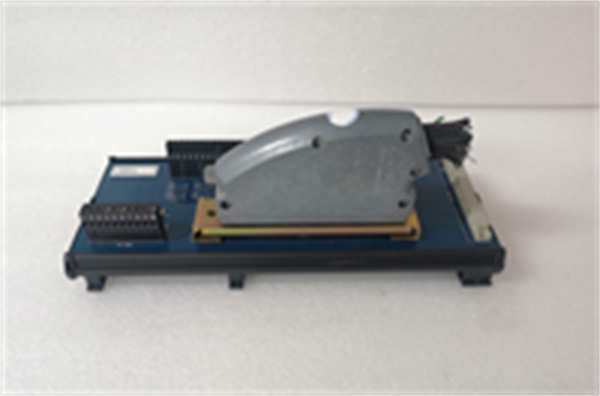

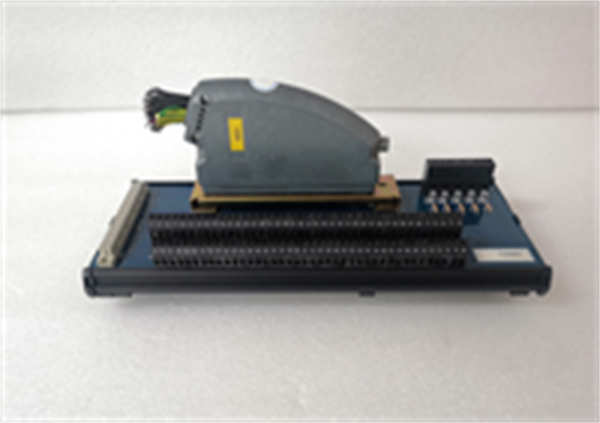

- Product Model: T8850

- Manufacturer: ICS Triplex / Schneider Electric (Triconex)

- System Family: Triconex TMR Safety Instrumented System (SIS)

- Module Type: Main Processor (MP) – central processing unit

- Redundancy Architecture: Triple-Modular Redundant (TMR) with hardware voting

- Compatible Chassis: 4328A, 4329A (legacy Triconex main frames)

- Memory: Onboard application memory (battery-backed SRAM in older revisions)

- Diagnostics: Continuous Built-In Test (BIT), front-panel status LEDs, fault reporting to diagnostic port

- Mounting: Hot-swappable in designated MP slots of Triconex chassis

- Safety Certification: SIL 3 per IEC 61508 and IEC 61511

- Firmware Dependency: Application compatibility tied to specific firmware revision

System Role and Downtime Impact

The T8850 serves as the central logic engine in legacy Triconex safety systems, executing safety applications that monitor process conditions and trigger emergency actions—such as closing ESD valves or tripping turbines. Deployed in oil & gas, refining, and chemical plants, it operates in a TMR configuration where three independent processors execute the same logic and vote on outputs to ensure fault tolerance. If one T8850 fails, the system continues operating; however, if a second fails before replacement, the entire safety function may go into a fail-safe state, forcing an unplanned plant shutdown. Because the MP module contains the compiled safety application, its failure or corruption can halt all safety logic execution, directly impacting operational continuity and regulatory compliance.

Reliability Analysis and Common Failure Modes

Despite its robust TMR design, the T8850 is susceptible to age-related failures after 15–20 years of service. The most common issue is battery-backed SRAM degradation in older revisions, leading to application loss during power cycles—especially if the onboard lithium battery has not been replaced per maintenance schedule. Second, connector wear on the backplane interface causes intermittent communication with I/O modules or the other MP units, triggering spurious faults or redundancy loss. Third, capacitor aging on internal power rails results in voltage instability during transients, causing unexpected resets or BIT failures.

A critical vulnerability lies in firmware and application version control: installing a T8850 with mismatched firmware can prevent chassis synchronization or cause logic errors. Additionally, the module generates significant heat during operation; inadequate cabinet cooling accelerates component stress.

For preventive maintenance, verify battery voltage annually and replace every 5–7 years regardless of reading. Inspect backplane connectors for corrosion or bent pins during outages. Monitor diagnostic logs in TriStation 1131 for “MP Sync Loss” or “Voter Mismatch” events. Ensure ambient temperature remains below 60°C and maintain clean airflow around the chassis. Always keep a spare T8850 loaded with the exact same application and firmware version as the installed unit.

T8850 ICS

Lifecycle Status and Migration Strategy

Schneider Electric has discontinued the T8850 as part of the transition to modern Triconex platforms such as eXP and eXPe. No new units are manufactured, and long-term repair services are being phased out. Continued use carries high risk due to diminishing spares, rising costs, and lack of technical support for legacy firmware.

As an interim measure, maintain at least one certified, application-loaded spare with full traceability and test documentation. Only use units refurbished by Schneider-approved vendors who validate TMR synchronization and memory integrity under load.

For long-term sustainability, Schneider Electric’s recommended migration path is to the Triconex eXP platform, using modern Main Processor modules such as the 4328E MP. This upgrade requires:

- Replacing the legacy chassis with an eXP-compatible frame

- Recompiling and downloading the safety application in a current version of TriStation 1131

- Re-validating all safety functions per IEC 61511, including updated SIL verification

- Potentially replacing legacy I/O modules with eXP-compatible equivalents

Given the regulatory and safety implications, any migration must follow a formal Management of Change (MOC) process and involve a qualified functional safety engineer. A phased approach—starting with non-critical safety loops—can reduce risk while preserving operational integrity. Early engagement with a Schneider-certified Triconex integrator is essential to plan, execute, and document the transition effectively.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: