Description

Technical Specifications (For Spare Parts Verification)

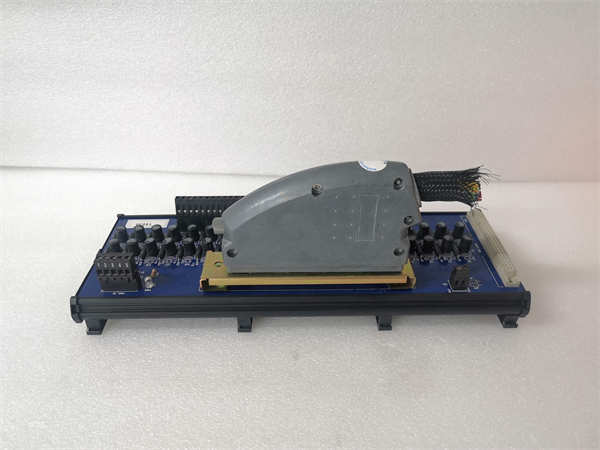

- Product Model: ICS T8830

- Manufacturer: Triconex (Schneider Electric)

- System Platform: Tricon v10 (Version 10) Safety Instrumented System

- Architecture: Triple-Modular Redundant (TMR) with synchronized processors and voter circuitry

- Processor Type: Proprietary RISC-based CPUs (three identical units per module)

- Memory: Onboard program and data memory with battery-backed SRAM (battery type: BR2330 or equivalent)

- Communication: Supports TriBus internal backplane; interfaces with I/O modules via high-speed redundant links

- Diagnostic Coverage: >99.99% fault detection via continuous self-test and cross-comparison

- Operating Temperature: 0°C to +60°C (derated above 50°C)

- Power Consumption: Approximately 25 W (varies with load and I/O configuration)

- Physical Form: Full-height plug-in module for Tricon v10 main chassis (typically 17–19″ rack mounted)

System Role and Downtime Impact

The ICS T8830 is the heart of a Tricon v10 safety system, commonly deployed in oil & gas, petrochemical, and power generation facilities where SIL 3 compliance is required. It executes safety logic—such as emergency shutdown (ESD), burner management (BMS), or high-integrity pressure protection (HIPPS)—using true TMR architecture: three independent processors execute the same logic simultaneously, and a hardware voter ensures output consistency. If one processor fails, the system continues operating without interruption. However, if the ICS T8830 module itself suffers a catastrophic failure (e.g., power surge, internal short, or firmware corruption), the entire Tricon chassis may go into a safe state, triggering a plant-wide trip. Given its role in life-safety and asset-protection systems, unplanned failure can result in multi-million-dollar production losses and regulatory scrutiny.

Reliability Analysis and Common Failure Modes

Although Triconex systems are renowned for reliability, the ICS T8830—now often 15–25 years old—is susceptible to age-related degradation:

- Battery leakage: The onboard SRAM backup battery (typically 10-year life) can leak after prolonged service, corroding PCB traces and causing memory loss or boot failures.

- Capacitor aging: Electrolytic capacitors in the power regulation circuit degrade, leading to voltage ripple, intermittent resets, or failure to power up.

- Backplane connector wear: Repeated insertion/removal or thermal cycling causes fretting corrosion on edge connectors, resulting in communication errors with I/O modules.

- Firmware corruption: Rare but possible due to power anomalies during write cycles, especially if battery voltage is marginal.

Preventive maintenance should include annual battery voltage checks, visual inspection for capacitor bulging or electrolyte residue, cleaning of module edge fingers with contact cleaner, and periodic full-system diagnostics using Triconex Enhanced Diagnostic Monitor (EDM) software. Keeping a powered spare module in a test rack is strongly advised.

ICS T8830

Lifecycle Status and Migration Strategy

Schneider Electric has formally obsoleted the Tricon v10 platform, including the ICS T8830. While limited repair services may exist through authorized partners, no new modules are manufactured. Continued operation carries escalating risk: spare availability is declining, and technical expertise is becoming scarce.

Short-term mitigation includes sourcing certified tested spares, implementing rigorous preventive maintenance, and maintaining a hot-standby chassis if feasible.

The official migration path is to Triconex Trident (based on Tricon v11/v12 hardware) or the newer Tricon CX platform. This transition preserves existing safety logic (via conversion tools) but requires:

- Replacement of the main chassis and all processor modules

- Potential re-wiring if I/O terminal blocks are not compatible

- Re-validation of the entire SIS to meet current IEC 61511 requirements

For facilities planning long-term operational continuity, initiating a migration feasibility study is strongly recommended—before a critical failure forces an emergency response.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: