Description

Key Technical Specifications (For Spare Parts Verification)

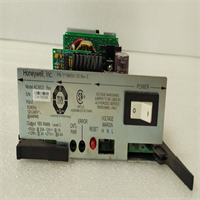

- Product Model: TK-PRR021

- Manufacturer: Honeywell

- System Platform: TDC 3000 / Total Plant Solution (TPS) – HPM or History Module chassis

- Part Number: 51309288-275

- Output Voltages: +5 VDC (primary logic), +15 VDC, –15 VDC (for analog I/O interfaces)

- Redundancy: Dual-module N+1 hot-swap capable (requires two units for full redundancy)

- Input Voltage: 100–240 VAC auto-ranging, 50/60 Hz

- Power Rating: Approximately 300 W total output capacity

- Mounting: Slide-in module for TPS 19″ rack chassis (e.g., HPM-A or HM-A)

- Status Indicators: Front-panel LEDs for AC OK, DC OK, and Fault

- Cooling: Forced air via chassis fan system; requires unobstructed airflow

System Role and Downtime Impact

The TK-PRR021 is installed in pairs within TPS HPM (controller) or HM (history/data logging) chassis to provide fault-tolerant power. In an HPM configuration, it powers the GUS (Global User Station) interface cards, IOP (Input/Output Processors), and communication modules. If one power supply fails, the redundant unit should carry the full load—but if both fail (or if only one is installed), the entire chassis loses power. This results in immediate loss of control for all associated I/O, process loops, and interlocks managed by that HPM. In continuous processes such as refineries or chemical plants, this can trigger a full unit trip or emergency shutdown. In HM applications, power loss leads to interruption of historical data collection, potentially violating regulatory data retention requirements.

Reliability Analysis and Common Failure Modes

Despite robust initial design, most TK-PRR021 units have exceeded their intended 15–20 year service life. Age-related degradation is now the dominant failure driver.

Common failure modes include:

- Fan bearing wear or seizure: Internal cooling fans stall due to dried lubricant, causing thermal shutdown or component overheating.

- Electrolytic capacitor aging: Bulk capacitors on the DC output rails lose capacitance, increasing ripple voltage and triggering false “DC Fault” alarms.

- Power transistor or rectifier failure: Thermal stress on switching components leads to open-circuit or short-circuit conditions, often accompanied by burnt odor or visible charring.

- Backplane connector arcing: Repeated insertion/removal or vibration causes contact resistance to rise, leading to intermittent power delivery.

Design weaknesses include:

- Limited diagnostic granularity—only basic OK/Fault LEDs, no remote health monitoring;

- Sensitivity to dirty or restricted airflow; even moderate dust buildup can cause thermal throttling;

- No power-factor correction (PFC), making it more susceptible to input voltage sags or harmonics.

Preventive maintenance recommendations:

- Clean chassis air filters and internal dust every 6 months;

- Perform annual infrared thermography on powered units to detect hot spots;

- Verify redundancy by simulating single-supply operation during planned outages;

- Maintain at least one fully tested spare per critical chassis.

-

Honeywell TK-PRR021 51309288-275

Lifecycle Status and Migration Strategy

Honeywell ended production of TPS hardware over 15 years ago. The TK-PRR021 is no longer covered under standard support contracts, and factory repair services are unavailable. Continued use carries significant operational and compliance risks, especially in regulated industries.

Interim mitigation strategies include:

- Procuring only from vendors who provide full load-test reports (including redundancy switchover validation);

- Installing external temperature and voltage monitors on critical chassis to provide early warning;

- Avoiding single-supply configurations—even if load permits, redundancy is essential for reliability.

Honeywell’s official migration path is Experion PKS, with options ranging from virtualized TPS emulation (using Experion’s TPS Migration Package) to full greenfield replacement with C300 controllers. For power infrastructure specifically, modern Experion racks use standardized, hot-swappable, N+1 redundant power supplies with SNMP and predictive diagnostics—eliminating reliance on obsolete proprietary modules.

A phased approach is recommended:

- Begin with non-critical HM or secondary HPM nodes;

- Leverage Honeywell’s migration tools to preserve existing control logic and graphics;

- Reuse field wiring where possible to reduce installation cost.

While migration requires capital investment, it eliminates recurring spare-part crises, reduces mean time to repair (MTTR), and aligns the facility with current cybersecurity and operational technology (OT) standards. For sites extending TPS life, a disciplined spare-parts management program—combined with enhanced monitoring—is essential to avoid catastrophic power-related failures.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: