Description

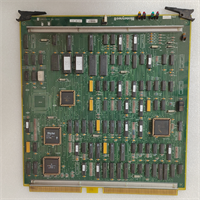

Technical Specifications (For Spare Part Verification)

- Model: TK-IOLI01

- Manufacturer: Honeywell

- System Family: Fail Safe Controller (FSC) 900 / 1000 Series

- Module Type: Digital Input Interface / Termination Unit

- Input Channels: 8 channels per module (configurable for dry contact or powered input)

- Input Voltage: 24 V DC nominal (compatible with passive contacts or active sources)

- Isolation: Channel-to-channel and channel-to-backplane isolation per IEC 61508

- Backplane Interface: Proprietary FSC bus for communication with central processors (e.g., CP-FSC)

- Diagnostic Coverage: Built-in line monitoring (open circuit, short circuit, cross-wire detection)

- LED Indicators: Per-channel status (power, fault, input state)

- Mounting: DIN-rail mounted within FSC I/O chassis, with removable terminal blocks

- Compliance: Certified for use in IEC 61508 SIL3 and ANSI/ISA 84.01 safety systems

System Role and Downtime Impact

The Honeywell TK-IOLI01 is a foundational component in legacy FSC-based safety instrumented systems (SIS), commonly deployed in refineries, chemical plants, and offshore platforms for emergency shutdown (ESD), burner management, and fire & gas detection. It serves as the trusted entry point for field safety signals into the FSC’s triple-modular redundant (TMR) or dual-channel architecture. If a TK-IOLI01 fails—due to internal electronics degradation or terminal corrosion—it may fail to detect a critical trip condition (e.g., high pressure, gas leak), preventing the SIS from actuating. Alternatively, it could generate a false trip, causing an unplanned plant shutdown. Because FSC systems often lack hot-swap capability and modern remote diagnostics, replacing a faulty module typically requires a controlled process shutdown, resulting in significant production loss.

Reliability Analysis and Common Failure Modes

Despite its robust design, the TK-IOLI01 is vulnerable to long-term reliability issues due to its age (many units installed over 15–20 years ago). The most common failure modes include:

- Degradation of optocouplers used for input isolation, leading to signal drift or missed transitions

- Corrosion on terminal block screws or internal PCB traces in high-humidity or corrosive environments

- Electrolytic capacitor aging in the local power regulation circuit, causing intermittent resets or diagnostic faults

- Mechanical wear on the DIN connector pins, resulting in poor backplane contact and communication errors

Preventive maintenance recommendations include:

- Performing annual loop tests that verify both field signal detection and diagnostic reporting

- Inspecting terminal tightness and signs of oxidation during scheduled outages

- Monitoring module temperature via thermal imaging to detect abnormal heating

- Maintaining spare TK-IOLI01 modules in climate-controlled storage and powering them periodically to prevent “storage failure”

HONEYWELL TK-IOLI01

Lifecycle Status and Migration Strategy

Honeywell officially ended support for the FSC platform years ago, with the TK-IOLI01 no longer in production. No firmware updates, factory repairs, or genuine spares are available from the manufacturer. Continued operation relies on dwindling secondary-market inventory, where authenticity and prior usage history are often unknown—posing serious functional safety and compliance risks.

Short-term risk mitigation includes:

- Securing tested, traceable TK-IOLI01 units from specialized lifecycle vendors with burn-in validation

- Implementing board-level repair programs for known failure points (e.g., capacitor replacement)

- Enhancing redundancy by splitting critical functions across multiple I/O modules where possible

For long-term sustainability, Honeywell’s endorsed migration path is to transition to the Safety Manager platform (part of Experion HS). This modern SIL3-certified system offers enhanced diagnostics, cybersecurity features, and seamless integration with Experion PKS. The migration requires:

- Replacement of FSC chassis, I/O modules, and terminal blocks

- Re-engineering of safety logic using Safety Builder software

- Recertification of all safety instrumented functions (SIFs) under IEC 61511

While capital-intensive, this upgrade eliminates obsolescence exposure, improves operational visibility, and ensures continued compliance with evolving safety standards—making it a necessary investment for any facility dependent on reliable safety shutdown performance.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: