Description

Key Technical Specifications (For Spare Parts Verification)

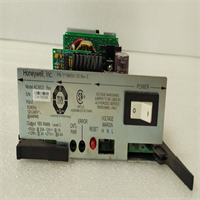

- Product Model: TK-IOLI01

- Manufacturer: Honeywell

- System Family: TDC 3000 / TotalPlant Solution (TPS)

- Part Number: 51403427-175

- Function: Analog Input Interface (typically supports 4–20 mA or 1–5 V signals)

- Mounting: Designed for installation in TPS I/O chassis (e.g., IOP or NIM-based racks)

- Communication: Interfaces via LCN (Local Control Network) backplane

- Power Requirement: Powered through TPS I/O backplane (typically +5 V, ±15 V rails)

- Diagnostic Capability: Basic LED status indicators; no advanced self-diagnostics

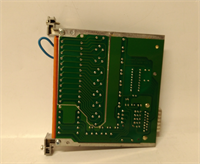

- Physical Form: Proprietary Honeywell TPS card format (approx. 6U height, Eurocard-compatible width)

-

Honeywell TK-IOLI01 51403427-175

System Role and Downtime Impact

The TK-IOLI01 is an integral component of the TPS I/O architecture, typically deployed in I/O processor (IOP) cabinets that serve as intermediaries between field instruments and the central LCN network. It conditions and isolates analog signals before they are digitized and transmitted to TPS controllers (HPMs or HMIs). If this module fails, all associated analog input channels—often tied to pressure, temperature, or flow measurements in critical process units—become unavailable. In continuous-process industries like refining or chemicals, such a failure can trigger safety interlocks, force manual operation, or lead to unplanned shutdowns of entire process trains, resulting in significant production loss and potential safety exposure.

Reliability Analysis and Common Failure Modes

Many TPS systems with TK-IOLI01 modules remain operational due to their original robust design and stable process environments. However, after 20+ years of service, aging effects dominate failure mechanisms. The most common failure mode is electrolytic capacitor degradation on the internal power regulation circuitry, leading to intermittent signal dropout or complete module blackout. Additionally, corrosion on edge connectors from prolonged exposure to industrial atmospheres can cause communication errors with the backplane. A notable design weakness is the lack of redundant power paths and minimal transient protection on field wiring terminals, making the module vulnerable to voltage surges from lightning or switching events.

For maintenance teams, proactive measures are essential. Focus inspections on the module’s front-panel LEDs for abnormal behavior (flickering, no power indication). During scheduled outages, remove the module and inspect for bulging capacitors, burnt traces, or oxidized connector fingers. Clean backplane slots with contact enhancer spray. Most critically, verify the integrity of field wiring shields and grounding—poor grounding accelerates noise-induced failures in these legacy analog interfaces.

-

Honeywell TK-IOLI01 51403427-175

Lifecycle Status and Migration Strategy

Honeywell formally discontinued the TK-IOLI01 and the broader TPS I/O subsystem well over 15 years ago. Continuing to operate systems dependent on this module carries substantial risk: genuine spare parts are scarce, counterfeit units occasionally appear on the gray market, and factory-level repair services no longer exist. Technical documentation is archived, and few engineers retain hands-on TPS expertise.

In the short term, facilities may rely on verified surplus inventory or third-party board-level repair services specializing in TDC 3000 hardware. However, these are stopgap measures. The only sustainable path is full migration to a modern DCS platform. Honeywell’s recommended migration route is to Experion PKS, which requires replacing the entire TPS control and I/O infrastructure. This involves re-engineering I/O assignments, re-commissioning control strategies, and retraining personnel—but eliminates long-term obsolescence risk. For budget-constrained sites, a phased migration (e.g., replacing one unit at a time) or hybrid integration (using protocol converters to bridge TPS data into PKS) may be considered, though these introduce complexity and potential single points of failure. Planning should begin now, as lead times for engineering and execution are substantial.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: