Description

Key Technical Specifications (For Spare Parts Verification)

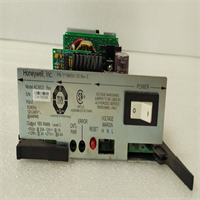

- Product Model: TC-PPD011

- Manufacturer: Honeywell

- System Family: Experion Process Knowledge System (PKS) – C300 architecture

- Output Voltage: 24 V DC (regulated)

- Output Current: 10 A continuous (per module, supports parallel redundancy)

- Input Voltage: 100–240 V AC, 50/60 Hz (auto-ranging)

- Redundancy Mode: Parallel, load-sharing with automatic failover

- Mounting: DIN rail (TS-35) within C300 I/O or controller cabinets

- Diagnostic Indicators: LEDs for POWER OK, FAULT, and REDUNDANCY STATUS

- Connector Type: Screw-terminal blocks for AC input and DC output

- Operating Temperature: 0°C to +60°C

System Role and Downtime Impact

The TC-PPD011 is a foundational power component in Honeywell Experion PKS C300-based distributed control systems, widely used in refining, chemical, and power applications. It supplies conditioned 24 V DC power to the C300 controller chassis and its I/O modules, typically deployed in redundant pairs to ensure continuous operation. If one unit fails, the system continues on the remaining supply—but if both fail (or the second fails before replacement), the entire C300 rack may lose power, causing immediate loss of control over connected field devices. This can result in emergency shutdowns, safety system activation, or manual intervention requirements. Given its role in powering critical logic solvers, unplanned failure carries high operational and safety risk.

Reliability Analysis and Common Failure Modes

After 10–15 years of service, the TC-PPD011 exhibits predictable aging patterns. The most frequent failure mode is electrolytic capacitor degradation in the primary and secondary circuits, leading to output voltage instability, increased ripple, or complete shutdown under load. Second, thermal stress on switching components (e.g., MOSFETs, transformers) from prolonged high-temperature operation—especially in poorly ventilated cabinets—can cause intermittent faults or thermal runaway. Third, loose or corroded terminal connections create high-resistance points that overheat, potentially damaging wiring or triggering nuisance trips.

A key limitation is the lack of remote health monitoring; diagnostics are limited to local LEDs, so a degraded unit may operate marginally until it fails during a peak demand event. Additionally, the module relies on passive convection cooling, making it vulnerable to dust accumulation and ambient heat buildup.

For preventive maintenance, measure output voltage under full load—verify it remains within 24 V ±2%. Inspect for bulging or leaking capacitors during cabinet inspections. Tighten terminal screws to manufacturer torque specifications. Ensure adequate airflow around the unit and keep heatsinks free of dust. Monitor C300 diagnostic logs for unexpected power-related events or module reboots.

HONEYWELL TC-PPD011

Lifecycle Status and Migration Strategy

Honeywell has discontinued the TC-PPD011 as part of the platform evolution toward newer Experion PKS architectures (e.g., C300 R400+, LE/SM series). No new units are manufactured, and official repair or technical support is no longer available. Continued reliance on this module increases exposure to obsolescence risk, with spare availability declining and pricing volatility rising.

As an interim measure, maintain at least one tested and verified spare unit per critical cabinet. Prioritize vendors who provide burn-in test reports under full load and thermal stress. Consider third-party refurbishment only from providers who perform full capacitor replacement (“re-capping”) and functional validation.

For long-term sustainability, Honeywell’s strategic direction favors migration to modern redundant power supplies compatible with current Experion platforms. However, direct replacement in legacy C300 systems is often feasible using industrial-grade, certified 24 V DC redundant power supplies from reputable manufacturers (e.g., Weidmüller, Phoenix Contact) that match electrical, mechanical, and signaling specifications. Key validation steps include:

- Confirming identical output current, voltage tolerance, and transient response

- Ensuring terminal layout and DIN-rail dimensions are compatible

- Verifying fault signaling (e.g., relay contact or LED status) aligns with existing diagnostics

This approach preserves system functionality while mitigating supply chain risk. Early consultation with a Honeywell-certified system integrator is recommended to assess compatibility, validate performance, and ensure compliance with safety and cybersecurity requirements during any hardware substitution.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: