Description

Technical Specifications (For Spare Part Verification)

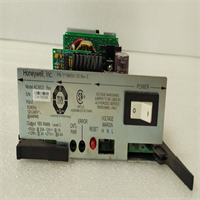

- Model: TC-FPCXX2

- Manufacturer: Honeywell

- System Family: Experion PKS (Process Knowledge System), specifically for Fieldbus-enabled I/O solutions

- Function: Fieldbus Power Conditioner / Coupler

- Input Voltage: Typically 24 V DC from system power rail

- Output Voltage: Regulated 15–18 V DC @ up to 500 mA per segment (depending on variant)

- Communication Interface: FOUNDATION Fieldbus H1 (31.25 kbit/s)

- Signal Isolation: Galvanic isolation between host system and field segment

- Intrinsic Safety Option: Available in IS (FISCO/Entity) and non-IS versions—verify label (e.g., TC-FPCXX2-IS)

- Diagnostic Features: LED indicators for power, communication activity, and fault status

- Mounting: DIN-rail or chassis-mounted within Fieldbus interface assemblies (e.g., FIM or FI820F cabinets)

- Compliance: IEC 61158, IEC 61508 (for safety-related use), and FOUNDATION Fieldbus Registered Product

System Role and Downtime Impact

The Honeywell TC-FPCXX2 is a critical enabler of digital field instrumentation in legacy Experion PKS installations. It powers and electrically isolates a FOUNDATION Fieldbus H1 segment that may host 8–16 smart devices—including pressure transmitters, control valves, and temperature sensors. If the TC-FPCXX2 fails due to internal regulator breakdown or signal coupling degradation, the entire segment goes offline. This results in loss of both measurement and control for all connected loops, often triggering alarms, fallback to manual mode, or even process trips in tightly integrated units like distillation columns or reactors. Because Fieldbus segments are typically not redundant in older designs, this module represents a single point of failure with cascading operational consequences.

Reliability Analysis and Common Failure Modes

Although designed for industrial environments, the TC-FPCXX2 is susceptible to long-term reliability issues due to its reliance on aging power electronics. Common failure modes include:

- Output voltage droop or instability caused by degraded electrolytic capacitors in the DC-DC converter stage

- Intermittent communication due to cracked solder joints on the signal transformer or isolation barrier

- Overheating and shutdown triggered by dust accumulation or inadequate cabinet ventilation

- Damage from voltage surges on the field side if surge protection was not properly installed

Recommended preventive actions include:

- Monitoring segment current draw during routine diagnostics; sudden increases may indicate failing devices stressing the power conditioner

- Verifying output voltage at the Fieldbus terminator under load (should remain >15 V)

- Inspecting for discoloration or bulging on the module casing—signs of internal overheating

- Ensuring proper grounding of the Fieldbus shield to minimize noise-induced communication errors

HONEYWELL TC-FPCXX2

Lifecycle Status and Migration Strategy

Honeywell has phased out the TC-FPCXX2 as part of its broader shift away from discrete Fieldbus power conditioners toward integrated I/O solutions like the Universal I/O (UIO) platform and ControlEdge devices. The module is no longer listed in active catalogs, and technical support is limited to existing service agreements. Continued reliance on obsolete units increases exposure to unplanned downtime and compliance gaps, especially as cybersecurity standards evolve.

Short-term risk mitigation includes:

- Securing tested, labeled TC-FPCXX2 units (confirming IS vs. non-IS version) from certified automation lifecycle vendors

- Maintaining spare Fieldbus segments on isolated test benches for rapid validation

- Installing external segment monitors to detect early signs of power or signal degradation

For long-term sustainability, Honeywell recommends migrating to ControlEdge™ Fieldbus I/O or transitioning high-value loops to HART-over-analog or Ethernet-APL architectures. This involves:

- Replacing legacy Fieldbus power conditioners with modern, supported alternatives (e.g., Pepperl+Fuchs, Moore Industries, or Honeywell-approved third-party units)

- Upgrading device description (DD) libraries and asset management tools in Experion

- Revalidating loop performance and cybersecurity posture post-migration

While Fieldbus remains functional in many plants, replacing obsolete infrastructure like the TC-FPCXX2 restores reliability, simplifies spares management, and aligns the facility with future-ready digital strategies—making it a prudent step for any site planning operation beyond the next decade.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: