Description

Key Technical Specifications (For Spare Parts Verification)

- Product Model: SDI-1624

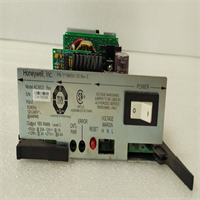

- Manufacturer: Honeywell

- System Family: Fail Safe Controller (FSC) 9000 / 1000 series

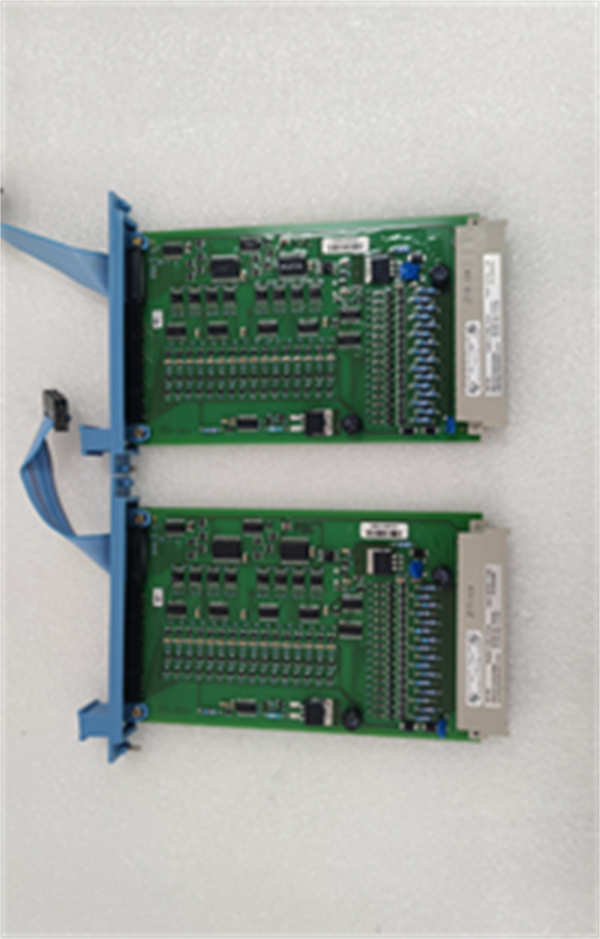

- Module Type: Digital Input (DI), 16 channels

- Input Voltage: 24 V DC (nominal), compatible with dry contacts or powered sources

- Input Type: Sink or source configuration (field-configurable via jumpers or backplane)

- Safety Certification: Part of SIL 3 certified FSC architecture per IEC 61508

- Redundancy Support: Used in redundant FSC configurations (dual or triple)

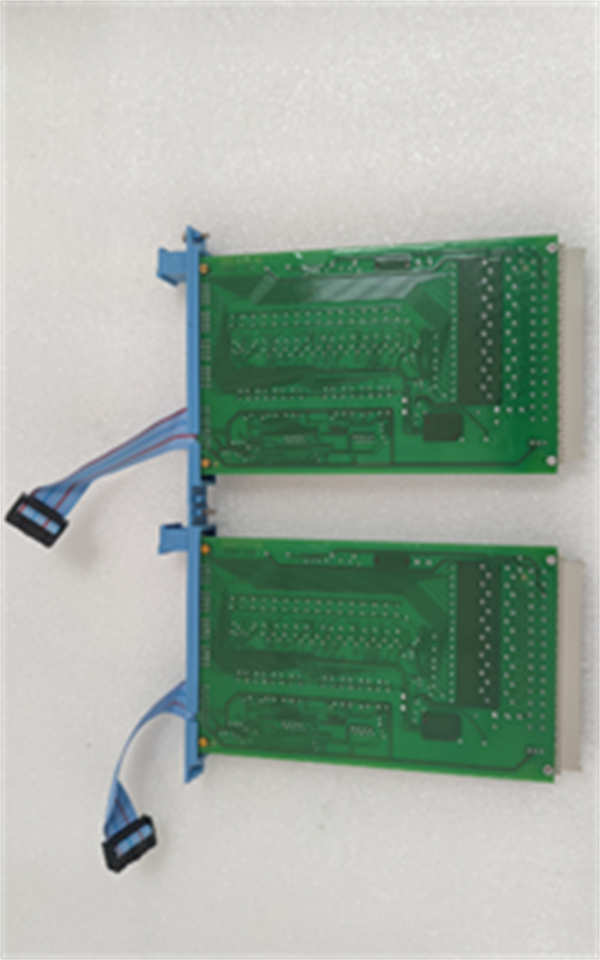

- Mounting: Plugged into FSC I/O chassis (e.g., FSC-MPU or FSC-IO base units)

- Diagnostics: Channel-level LED indicators, fault reporting to FSC controller

- Connector: Screw-terminal field wiring blocks (typically 0.5–2.5 mm²)

System Role and Downtime Impact

The SDI-1624 is a foundational input interface in Honeywell FSC-based safety instrumented systems, widely deployed in oil & gas, chemical, and power generation facilities. It reads discrete signals from field devices such as emergency shutdown switches, valve position limit switches, fire/gas detectors, and motor status contacts. These inputs feed directly into the FSC’s safety logic solver, which determines whether to initiate a shutdown sequence. If the SDI-1624 fails—due to internal fault, power loss, or communication error—the FSC may interpret missing inputs as unsafe conditions, potentially triggering a full plant trip. In redundant configurations, a single module failure may be tolerated, but a second failure in the same voting group can compromise the entire safety function. Replacement requires system de-energization or hot-swap capability (if supported), followed by re-verification of all 16 input circuits.

Reliability Analysis and Common Failure Modes

Despite its robust design for safety-critical service, the SDI-1624 is subject to age-related degradation after 15–20 years. The most common failure mode is opto-isolator aging, where the internal optical couplers degrade due to prolonged current flow, leading to increased leakage or complete signal dropout—especially on channels with high switching frequency. Second, terminal block corrosion or loosening causes intermittent contact, resulting in flickering inputs that may trigger nuisance alarms or false trips. Third, power supply filtering capacitor wear on the module’s internal DC/DC converter leads to voltage instability during transients, causing resets or diagnostic faults.

A key vulnerability lies in its dependence on external field wiring quality: short circuits, ground loops, or induced noise from nearby AC cables can damage input circuits or mimic real signals. Additionally, older revisions lack modern diagnostics, making latent faults difficult to detect without manual loop checks.

For preventive maintenance, perform full input loop tests during scheduled proof tests per IEC 61511. Inspect and re-torque terminal connections. Verify LED status matches actual field device states. Monitor FSC diagnostic logs for “input stuck” or “channel fault” events. Ensure ambient temperature remains within 0°C to +60°C and cabinets are free of dust and moisture.

HONEYWELL SDI-1624

Lifecycle Status and Migration Strategy

Honeywell has discontinued the SDI-1624 as part of the broader phase-out of the legacy FSC platform, which has been succeeded by the Safety Manager and Experion HS (Highly Secure) safety systems. No new modules are produced, and official technical support is extremely limited. Continued use carries significant risk due to shrinking spare availability, rising costs, and inability to obtain firmware or configuration tools.

As a temporary measure, maintain at least one fully tested spare unit per critical I/O group. Prioritize vendors who provide functional test reports under load and thermal stress. Avoid untested surplus stock, as internal opto-isolator degradation is not visible externally.

For long-term sustainability, Honeywell’s strategic migration path is to Experion HS, a modern SIL 3-certified safety platform with enhanced cybersecurity, remote diagnostics, and Ethernet-based I/O. This transition involves:

- Replacing FSC controllers and I/O chassis with Experion HS equivalents

- Rewiring or adapting field connections to new I/O modules (e.g., HS-DI16)

- Re-engineering and re-validating all safety logic in Safety Builder software

- Conducting full SIL verification and functional testing

In some cases, a hybrid approach may be viable: using external safety relays or small safety PLCs (e.g., PILZ PNOZ) to handle non-critical discrete inputs, reducing dependency on legacy FSC I/O. However, this must be carefully assessed for architectural compliance.

Given the regulatory and operational stakes, any migration must follow a formal Management of Change (MOC) process and involve a qualified functional safety engineer. Early engagement with a Honeywell-certified safety system integrator is strongly recommended to evaluate options, plan execution, and ensure continued compliance with process safety standards.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: