Description

Technical Specifications (For Spare Parts Verification)

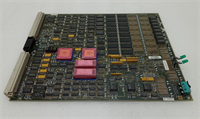

- Product Model: FC-PSU-UNI2450U V1.0

- Manufacturer: Honeywell Process Solutions

- System Platform: Experion® Safety Manager (SM) series

- Output Voltage: 24 VDC ±3%

- Output Current: 2.1 A continuous

- Output Power: 50 W

- Input Voltage Range: 85–264 VAC / 100–370 VDC (universal)

- Efficiency: Approximately 88% at full load

- Mounting: Standard 35 mm DIN rail (TS35/7.5)

- Redundancy Support: Designed for parallel operation with diode-or’ing for N+1 redundancy

- Certifications: IEC 61508 SIL 3, UL 61010-1, CSA C22.2 No. 61010-1, CE

- Diagnostic Features: LED indicators for DC OK and AC OK; no remote signaling

System Role and Downtime Impact

The FC-PSU-UNI2450U V1.0 is a safety-certified power supply used exclusively within Honeywell’s Safety Manager architecture. It powers critical safety I/O cards and logic solvers that execute emergency shutdown (ESD), fire & gas (F&G), or burner management functions. In redundant configurations, two units operate in parallel to ensure continuous power during maintenance or single-unit failure.

If this power supply fails—due to internal component degradation or input surge—the affected safety channel may lose power, triggering a spurious trip (unplanned plant shutdown) or, worse, entering a dangerous undetected fault state if redundancy is compromised. Because it carries SIL 3 certification, its reliability is part of the overall safety loop validation. Replacement with a non-certified generic PSU invalidates the safety integrity level and violates regulatory compliance (e.g., OSHA PSM, IEC 61511).

Reliability Analysis and Common Failure Modes

Despite its robust industrial design, the FC-PSU-UNI2450U V1.0 is vulnerable to age-related degradation common in switch-mode power supplies:

- Electrolytic capacitor drying: The most prevalent issue—capacitors on the primary and secondary sides lose capacitance over time, leading to increased output ripple, thermal runaway, or sudden shutdown. Units installed before 2015 are at elevated risk.

- Thermal stress: Continuous operation near rated load in enclosed cabinets without adequate airflow accelerates semiconductor and capacitor aging.

- Input transient damage: Although rated for universal input, repeated exposure to voltage sags or surges (common in brownfield sites) can degrade MOVs and rectifier bridges.

- Redundancy diode failure: The internal OR-ing diodes used for parallel operation can fail shorted or open, compromising redundancy without visible indication.

A key weakness is the lack of remote diagnostics—the unit only provides local LEDs. There is no dry contact or communication interface to alert the control system of impending failure.

Preventive maintenance should include:

- Annual infrared inspection for hot spots

- Measuring output ripple under load (>100 mVpp indicates capacitor degradation)

- Verifying redundancy by simulating single-PSU failure during scheduled outages

- Replacing units proactively after 8–10 years of service, even if operational

Honeywell FC-PSU-UNI2450U V1.0

Lifecycle Status and Migration Strategy

Honeywell has discontinued the FC-PSU-UNI2450U V1.0 as part of its transition to newer Safety Manager hardware generations. It is no longer listed in current price books, and factory repair services are unavailable. Continuing to operate on aged units poses significant safety and compliance risks.

Short-term mitigation requires sourcing only from vendors who provide full-load burn-in test reports (24 VDC @ 2.1 A for 48 hours) and verification of intact safety certifications. However, even tested units may have reduced remaining life due to latent capacitor wear.

The official migration path is to upgrade to the current-generation Safety Manager power supply, such as the FC-PSU-24V50W-R or equivalent, which offers:

- Improved efficiency (>90%)

- Built-in remote signaling (relay contact for DC OK)

- Enhanced thermal performance

- Continued SIL 3 certification under IEC 61508:2010

This upgrade typically requires cabinet rewiring and re-validation of the safety loop, but it restores manufacturer support and ensures long-term compliance. For facilities unable to perform a full SIS upgrade, maintaining a tested spare pool and implementing predictive monitoring (e.g., output voltage trending via external sensors) are essential interim measures.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: