Description

Technical Specifications (For Spare Parts Verification)

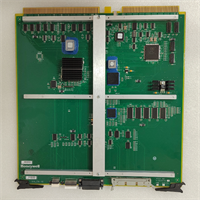

- Product Model: CC-PCNT02

- Manufacturer: Honeywell Process Solutions

- System Platform: Experion® PKS (R300–R510), installed in certified LG-series or third-party PKS-compliant workstations

- Interface Type: 32-bit PCI bus (5V signaling)

- Channels: 2 independent high-speed counter channels

- Input Type: TTL-compatible pulse inputs (0–5 VDC), non-isolated

- Maximum Count Rate: Up to 10 MHz per channel

- Functionality: Supports quadrature decoding, pulse direction sensing, and event timestamping

- Driver Dependency: Requires proprietary Honeywell kernel-mode driver integrated with PKS Station software

- Physical Form: Full-length PCI card with metal bracket and status LEDs

- Operating Environment: Intended for use only within Honeywell-certified industrial PCs under controlled temperature and EMI conditions

System Role and Downtime Impact

The CC-PCNT02 serves as a specialized data acquisition interface in Experion PKS systems where analog or digital I/O cannot capture rapidly changing pulse signals. It is typically deployed in applications such as natural gas flow measurement via turbine meters, steam turbine speed monitoring, or batch filling systems requiring precise pulse accumulation. Because this functionality is implemented at the PC hardware level—not through fieldbus or remote I/O—the card resides inside the operator or application server itself.

If the CC-PCNT02 fails—due to PCI bus incompatibility, driver corruption, or physical card malfunction—the associated pulse signals become unavailable to the PKS system. This may not cause an immediate plant trip, but it compromises measurement integrity. In fiscal metering applications, this could invalidate custody transfer records. In machinery protection contexts, loss of speed feedback might disable overspeed interlocks. Since the card is tightly coupled to specific OS and PKS versions, replacement is not plug-and-play, increasing recovery time during failures.

Reliability Analysis and Common Failure Modes

Although solid-state, the CC-PCNT02 is vulnerable due to its integration into aging PC platforms. Common failure modes include: PCI slot compatibility issues after motherboard replacements (especially when migrating to newer chipsets), driver conflicts following Windows updates or security patches, and signal noise-induced counting errors due to lack of galvanic isolation. The card’s reliance on 5V PCI signaling also makes it incompatible with modern 3.3V-only PCI/PCIe slots, limiting hardware upgrade paths.

A key weakness is its non-isolated inputs—ground loops or voltage spikes from field devices can damage the card or the host PC’s motherboard. Additionally, as host PCs age, capacitor degradation on the motherboard can cause unstable PCI bus timing, leading to intermittent counter lockups or data corruption.

Preventive measures include: using external signal conditioners with isolation for field pulses, ensuring strict adherence to Honeywell’s certified BOM during PC refreshes, disabling unnecessary OS services that interfere with real-time driver operation, and maintaining full system images of working configurations for rapid recovery.

HONEYWELL CC-PCNT02

Lifecycle Status and Migration Strategy

Honeywell has discontinued the CC-PCNT02 as part of its shift away from PCI-based embedded I/O toward networked and virtualized architectures in Experion PKS R520 and later. No direct replacement exists in current product lines, and driver support is absent in Windows 10 IoT Enterprise and newer PKS releases.

Short-term mitigation involves retaining original host PCs with verified working cards, creating golden disk images, and sourcing only tested surplus units with matching BIOS and OS baselines. However, this approach is unsustainable as PC hardware fails.

The strategic migration path is to replace pulse input functionality with networked or remote I/O solutions. Options include:

- Using a Honeywell X-Series I/O or Universal I/O (UIO) system with high-speed counter modules (e.g., XCNT01) connected via FTE, eliminating the need for internal PC cards.

- Deploying a third-party Modbus TCP or EtherNet/IP counter gateway that converts pulse inputs to register data, then integrating via OPC UA into PKS.

- For new projects, specifying smart flow meters with native digital communication (e.g., HART, Foundation Fieldbus) that transmit accumulated values directly, bypassing raw pulse handling entirely.

This transition requires engineering effort—including I/O re-mapping and logic updates—but restores long-term supportability, enhances cybersecurity posture, and removes dependency on obsolete PC expansion architectures.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: