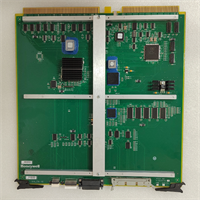

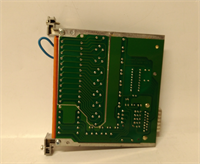

Description

Technical Specifications (For Spare Parts Verification)

- Model: CC-IP0101

- Manufacturer: HONEYWELL

- System Family: Experion Process Knowledge System (PKS), C300 Controller Platform

- Module Type: I/O Link Interface (dual-port, redundant)

- Mounting: Installed in C300 controller chassis (left-side slot)

- Communication Protocol: Honeywell Fault Tolerant Ethernet (FTE) over 100 Mbps full-duplex links

- Redundancy: Dual independent ports supporting synchronized hot-standby operation

- Data Rate: Up to 10,000 I/O points per second per link

- Diagnostic Indicators: LEDs for power, link status, redundancy sync, and fault

- Power Consumption: ~5 W (supplied via C300 backplane)

- Operating Temperature: 0°C to 60°C (industrial grade)

- Firmware Dependency: Requires compatible C300 controller firmware (typically R4xx or earlier)

System Role and Downtime Impact

The HONEYWELL CC-IP0101 is a critical communications enabler in Experion PKS systems built around the C300 controller. It serves as the primary interface through which the controller exchanges real-time I/O data with remote I/O racks—such as those housing FIM, DIM, or analog input modules—over the Fault Tolerant Ethernet (FTE) network.

In a non-redundant configuration, failure of the CC-IP0101 results in complete loss of I/O communication, halting all control logic execution that depends on field signals. Even in redundant setups, a single module failure forces switchover to the backup link; if the second module is degraded or misconfigured, this can cascade into a full controller fault. In continuous-process industries like oil refining, chemical production, or power generation, such an event can trigger emergency shutdowns, safety system activation, or manual intervention—posing operational, safety, and financial consequences.

Reliability Analysis and Common Failure Modes

While the CC-IP0101 is solid-state with no moving parts, its role in high-availability systems exposes it to long-term reliability challenges, particularly in electrically noisy or thermally stressed environments.

Common failure modes include:

- Ethernet PHY chip degradation due to sustained thermal stress, leading to intermittent packet loss or link drops.

- Capacitor aging on the internal DC/DC converter circuit, causing voltage instability and module reset loops.

- Corrosion or oxidation on the backplane edge connector, resulting in poor seating and communication errors.

- Firmware hang during boot sequence, often triggered by power cycling under marginal voltage conditions.

Design weaknesses include dependence on precise timing synchronization between redundant links—any skew can cause false failover events. Additionally, diagnostics are limited to basic link/status LEDs; deeper troubleshooting requires access to Experion’s system health logs.

Preventive maintenance recommendations:

- Monitor FTE network statistics in Experion for rising error counters or retransmissions.

- Ensure adequate cabinet ventilation to keep module temperature below 50°C.

- Perform annual inspection of backplane connectors for dust, debris, or discoloration.

- Maintain matched firmware versions across redundant CC-IP0101 pairs to avoid sync issues.

HONEYWELL CC-IP0101

Lifecycle Status and Migration Strategy

Honeywell has formally obsoleted the CC-IP0101 as part of its transition to the Experion LC and C400/C500 controller platforms, which use integrated, higher-bandwidth I/O interfaces without discrete link cards. Official repair services and new-unit sales have ceased, leaving users dependent on the secondary market.

Continued operation carries significant risk: untested spares may fail prematurely, and lack of vendor support complicates root-cause analysis during outages.

Short-term mitigation options include:

- Securing functionally tested spares from certified industrial automation suppliers with performance validation reports.

- Implementing proactive replacement of units installed prior to 2013.

- Enabling full redundancy (dual CC-IP0101 modules) if not already deployed.

For sustainable operation, Honeywell recommends migrating to the C400 or C500 controller platform within the Experion PKS ecosystem. This path involves:

- Replacing the C300 chassis with a C400/C500 unit (which integrates I/O networking directly).

- Retaining existing FTE cabling and remote I/O modules where compatible.

- Upgrading Experion software to a supported release (e.g., R550 or later).

- Re-downloading control strategies without major logic changes (typically no reprogramming required).

This migration restores access to security updates, technical support, and future-proof integration with cloud analytics and asset performance management tools via native OPC UA and MQTT support. A phased approach—starting with less critical process units—allows organizations to manage cost and risk while modernizing their control infrastructure.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: