Description

Key Technical Specifications (For Spare Parts Verification)

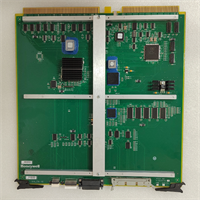

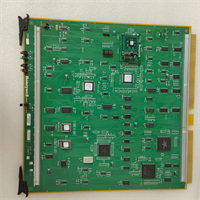

- Product Model: 8C-PCNT02

- Manufacturer: Honeywell

- System Platform: TDC 3000 / Total Plant Solution (TPS)

- Part Number: 51454363-275

- Function: PCN network interface terminal for GUS or application stations

- Network Type: Proprietary Honeywell PCN (coaxial-based, token-passing LAN)

- Data Rate: ~1 Mbps (typical for PCN)

- Physical Interface: Coaxial BNC or proprietary connector to PCN backbone

- Mounting: Internal card in industrial PC-based GUS or standalone terminal unit

- Power: Supplied via host workstation motherboard or external adapter

- Status Indicators: Typically includes link/activity LEDs (if front-accessible)

- Compatibility: Requires matching PCN firmware revision and TPS software version (e.g., R300–R400 series)

System Role and Downtime Impact

The 8C-PCNT02 serves as the critical communications gateway between a TPS operator workstation (GUS) and the central Process Control Network, which links HPM (High Performance Managers), HM (History Modules), and other system nodes. If this module fails—due to hardware fault, firmware corruption, or cable interface damage—the workstation loses all connectivity to live process data, alarms, trends, and control functions. While the underlying controllers may continue operating in auto mode, operators are effectively “blind,” unable to respond to abnormal conditions, acknowledge alarms, or perform manual interventions. In safety-critical or continuous processes (e.g., refineries, power plants), this loss of situational awareness significantly increases operational risk and may violate regulatory requirements for human oversight. Recovery typically requires physical replacement and reconfiguration, often during unplanned downtime.

Reliability Analysis and Common Failure Modes

Given its age (typically 20–25 years in service), the 8C-PCNT02 is highly susceptible to component aging and environmental stress.

Common failure modes include:

- Coaxial interface corrosion or impedance mismatch: Oxidation at BNC or backplane connectors causes signal reflection or loss, leading to intermittent PCN dropouts.

- EEPROM or configuration memory corruption: Loss of node address or network parameters due to CMOS battery failure renders the module unrecognizable on the PCN.

- Onboard oscillator drift: Timing crystal degradation disrupts token-passing synchronization, causing network collisions or exclusion from the PCN ring.

- Power regulation failure: Aging voltage regulators deliver unstable logic levels, resulting in erratic behavior or complete non-operation.

Design weaknesses include:

- Dependence on obsolete coaxial PCN architecture with no modern Ethernet fallback;

- Lack of remote diagnostics—failure detection relies on operator observation or network-wide alarm logs;

- Sensitivity to grounding loops and electrical noise, common in industrial environments.

Preventive maintenance recommendations:

- Verify PCN signal integrity annually using time-domain reflectometry (TDR) or oscilloscope checks;

- Replace CMOS batteries in host workstations every 3–5 years;

- Maintain spare modules in climate-controlled storage with ESD protection;

- Document exact firmware and node ID settings for rapid recovery.

-

Honeywell 8C-PCNT02 51454363-275

Lifecycle Status and Migration Strategy

Honeywell ended production and support for the 8C-PCNT02 and the broader TPS PCN infrastructure over 15 years ago. The module is not covered under current service contracts, and factory repair is unavailable. Continued reliance introduces escalating risk of extended outages due to unavailability of verified spares.

Interim mitigation strategies include:

- Procuring only from vendors who provide full network integration testing (i.e., successful boot and PCN registration in a live TPS test rack);

- Implementing redundant GUS workstations to reduce single-point dependency;

- Isolating critical workstations on dedicated PCN segments to limit fault propagation.

Honeywell’s strategic migration path is Experion PKS, which replaces the proprietary PCN with standard Ethernet/IP infrastructure. The TPS Migration Package allows virtualization of GUS functionality on modern servers while preserving existing graphics and control logic. This transition involves:

- Rehosting TPS applications on Experion-certified hardware;

- Replacing PCN with redundant Ethernet networks;

- Retaining field I/O where possible via HPM-to-C300 I/O migration kits.

For sites extending TPS life, maintaining a small inventory of tested 8C-PCNT02 modules—paired with rigorous network health monitoring—is essential. However, given the fragility of this legacy communications layer, planning a phased migration should be prioritized to ensure long-term operational resilience and compliance with modern OT security standards.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: