Description

Key Technical Specifications (For Spare Parts Verification)

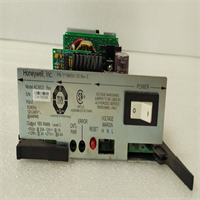

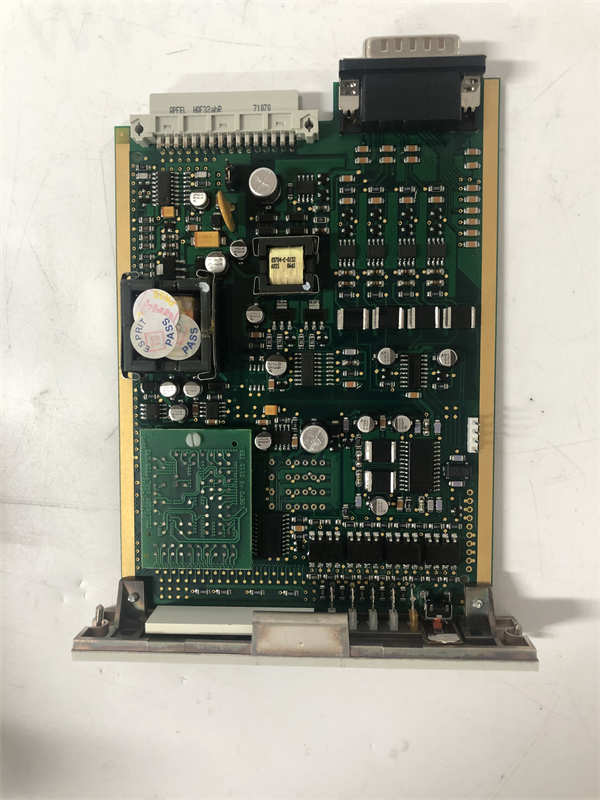

- Product Model: 05704-A-0145

- Manufacturer: HONEYWELL

- System Family: TDC 2000 / TDC 3000 Distributed Control System

- Module Type: High-Density Analog Input (AI) Module

- Channels: 16 differential inputs

- Input Range: ±10 VDC or 4–20 mA (software-configurable per channel)

- Isolation: Channel-to-channel and channel-to-backplane isolation (typically 500 VAC)

- Accuracy: ±0.1% of span (typical at 25°C)

- Update Rate: ~100 ms per channel (system-dependent)

- Backplane Interface: Proprietary TDC 3000 I/O bus (via NIM or LCN interface)

- Diagnostic Features: Open-circuit detection, overrange indication (limited)

- Physical Identifier: Label includes “05704-A-0145” and revision code (e.g., REV C); must match existing I/O configuration in NCF database

System Role and Downtime Impact

The HONEYWELL 05704-A-0145 is a foundational I/O module in legacy TDC 3000 systems, commonly deployed in refineries, petrochemical plants, and power generation facilities. It digitizes analog signals from field instruments—such as pressure transmitters on distillation columns or RTDs on reactor jackets—and delivers them to the controller for regulatory or supervisory control. A failure of this module results in loss of up to 16 critical process variables. Depending on system redundancy, this may cause multiple control loops to go into manual or fail-safe mode, degrading process stability. In non-redundant configurations, it can trigger alarms that cascade into unit trips or force operators into manual intervention under high cognitive load. Given the continuous nature of these processes, even partial loss of visibility can lead to off-spec product, safety excursions, or unplanned shutdowns with significant financial impact.

Reliability Analysis and Common Failure Modes

Many units have operated continuously for 20+ years. The most common failure modes include:

- Drift or complete failure of input conditioning circuits due to aging operational amplifiers or precision resistors, causing inaccurate readings

- Degradation of isolation barriers, leading to ground loops or cross-channel interference

- Corrosion or oxidation on the rear connector pins, resulting in intermittent signal loss

- Failure of internal DC-DC converters that power the analog front-end, often triggered by sustained voltage sags on the backplane

A key design limitation is the lack of comprehensive self-diagnostics—most faults manifest only as process anomalies, not module-level alerts. Additionally, the module relies on accurate configuration in the Network Control File (NCF); if the spare’s calibration constants differ from the original, it introduces systematic measurement errors that are difficult to trace.

Preventive maintenance recommendations include:

- Periodic loop calibration verification using known signal sources

- Inspection of I/O cabinet grounding and shielding integrity

- Archiving of NCF records and module-specific calibration data

- Storage of spares in static-controlled, dry environments to prevent connector oxidation

HONEYWELL 05704-A-0145

Lifecycle Status and Migration Strategy

Honeywell officially discontinued the 05704-A-0145 as part of the broader TDC 3000 end-of-life roadmap. No new units are available, and technical support is limited to break-fix under legacy service agreements. Continuing to operate with this module exposes facilities to increasing risk of extended downtime due to unavailability of tested spares.

As a short-term measure, organizations can source functionally tested surplus modules with calibration certificates, or engage specialized vendors for board-level repair—including component replacement and recalibration against NIST-traceable standards.

The strategic migration path is to transition to Honeywell Experion PKS, where analog inputs are handled by modern I/O platforms such as the FTE I/O or C300 controllers with remote I/O. This requires:

- Replacement of TDC 3000 HMIs, controllers, and I/O racks

- Re-engineering of control strategies in Experion Studio

- Recalibration of all field instruments to match new I/O characteristics

For facilities not ready for full DCS replacement, a hybrid approach—using TDC 3000-to-Experion gateways or third-party protocol converters (e.g., Modbus TCP to LCN)—can extend system life while enabling limited integration with modern supervisory layers. However, this does not eliminate the underlying hardware obsolescence risk. A phased migration plan, prioritizing highest-risk I/O racks, is strongly recommended to maintain operational continuity and regulatory compliance.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: