Description

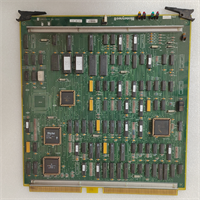

Key Technical Specifications (For Spare Parts Verification)

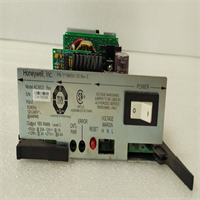

- Product Model: 05701-A-0511

- Manufacturer: Honeywell

- System Family: TDC 2000 (Total Distributed Control)

- Module Type: High-Level Analog Input (HLAI)

- Input Channels: 16 differential analog inputs

- Signal Range: 4–20 mA or 1–5 V DC (field-selectable via jumpers)

- Resolution: 12-bit A/D conversion

- Isolation: Channel-to-channel and channel-to-backplane isolation (typically 500 VDC)

- Update Rate: Approximately 100 ms per channel (system-dependent)

- Mounting: Requires TDC 2000 I/O chassis with compatible power and data backplane

- Power Consumption: ~8–10 W (supplied via TDC backplane rails)

- Diagnostic Features: Basic open-circuit detection; no digital self-test or calibration memory

- Configuration: Set via physical jumpers and DIP switches on the module

System Positioning and Downtime Impact

The Honeywell 05701-A-0511 is a foundational I/O module in TDC 2000 systems, which were widely deployed in refineries, chemical plants, and power stations from the 1980s through the early 1990s. It resides in remote I/O cabinets or main control racks, converting analog field signals into digital data for use by the TDC 2000 LCN (Local Control Network) processors. These signals often feed regulatory control loops (e.g., level control in a distillation column) or safety interlocks.

If this module fails—due to power surge, component drift, or connector corrosion—it can cause multiple process variables to read as invalid or fixed values. Depending on loop configuration, this may trigger alarms, force loops into manual mode, or initiate automatic shutdown sequences. In facilities still operating TDC 2000 due to asset longevity, such failures can lead to production instability or unplanned outages, particularly if redundant I/O was not originally implemented.

Reliability Analysis and Common Failure Modes

Despite its age, many 05701-A-0511 modules remain functional due to conservative analog design. However, several failure mechanisms are now prevalent. The most common is degradation of precision resistors and capacitors in the signal conditioning circuitry, leading to measurement drift outside acceptable tolerances (±0.1% typical spec). Electrolytic capacitors in the local power regulation stage also dry out over time, causing intermittent resets or complete loss of output data. Additionally, the edge connectors and terminal block interfaces are prone to oxidation, especially in humid or corrosive environments, resulting in noisy or lost signals.

A key vulnerability is the lack of onboard calibration storage or self-diagnostics. Unlike modern I/O, this module cannot report health status or compensate for drift—making faults detectable only through external verification.

Recommended preventive maintenance includes:

- Performing annual loop calibration checks using a certified mA/V source

- Inspecting terminal blocks for corrosion or loose screws

- Verifying jumper settings match system documentation

- Testing spare modules under load for at least 48 hours before installation to expose latent defects

HONEYWELL 05701-A-0511

Lifecycle Status and Migration Strategy

Honeywell discontinued the TDC 2000 platform in the late 1990s, replacing it with Experion PKS. The 05701-A-0511 has been obsolete for over 25 years, with no official support, repairs, or technical assistance available. Continuing to operate TDC 2000 systems carries escalating risk: spares are finite, expertise is retiring, and integration with modern cybersecurity or asset management systems is impractical.

Short-term mitigation involves sourcing tested surplus modules and maintaining a validated spare pool. Some third-party vendors offer “remanufactured” units with refreshed components, though long-term reliability remains uncertain.

The definitive solution is migration to a modern DCS such as Honeywell Experion PKS or ControlEdge UOC. Honeywell provides formal migration paths, including:

- I/O wiring reuse via adapter terminals

- Logic conversion tools for basic regulatory strategies

- Emulation options for operator graphics during transition

Migration typically requires full re-engineering of control logic, revalidation of safety functions, and operator retraining—but eliminates obsolescence exposure and enables advanced process analytics, remote access, and compliance with current IEC 62443 standards. Given the age of remaining TDC 2000 installations, organizations should treat migration as a strategic priority rather than a capital option.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: