Description

Key Technical Specifications (For Spare Parts Verification)

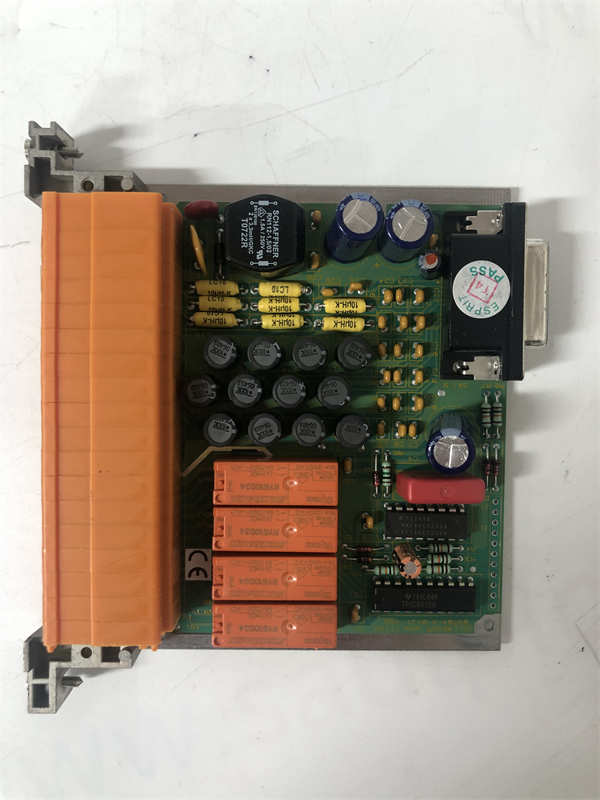

- Product Model: 05701-A-0361

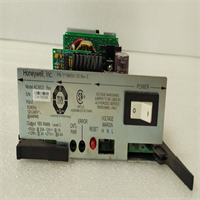

- Manufacturer: Honeywell

- System Family: TDC 2000 (Total Distributed Control)

- Module Type: Digital Input (DI)

- Input Channels: 16 isolated discrete inputs

- Input Type: Accepts dry contacts or powered DC signals (typically 24–48 VDC, field-powered)

- Wetting Voltage: Some versions include internal “wetting” voltage (~5–10 VDC) for dry contact compatibility—verify by label or documentation

- Isolation: Channel-to-backplane isolation (typically 500 VDC); no channel-to-channel isolation

- Response Time: <10 ms typical

- Mounting: Requires TDC 2000 I/O chassis with compatible data and power backplane

- Power Consumption: ~5–8 W (supplied via backplane)

- Configuration: Fixed function; input interpretation handled by TDC controller logic

- Diagnostics: None – no open-circuit detection, ground fault indication, or health reporting

System Positioning and Downtime Impact

The Honeywell 05701-A-0361 is a foundational monitoring module in legacy TDC 2000 installations across oil & gas, chemical processing, and power generation. It reads binary status from critical field assets—such as “pump running,” “valve closed,” or “high-high level switch activated”—and feeds this data into safety interlocks, sequence logic, or operator displays.

A failure in this module can manifest as:

- Stuck-on or stuck-off inputs, causing the DCS to believe a valve is closed when it’s open (or vice versa)

- Missed trip conditions, such as failure to detect a high-level alarm switch closure

- Nuisance shutdowns due to phantom contact closures from noise or leakage

Because many TDC 2000 systems lack input redundancy, a single faulty DI module can compromise process safety or force manual operation—increasing operator workload and risk during abnormal events.

Reliability Analysis and Common Failure Modes

Despite its robust industrial design, the 05701-A-0361 is now well beyond its intended service life. Common failure mechanisms include:

- Optocoupler degradation: The primary isolation component ages, leading to increased leakage current or complete failure to register input changes.

- PCB contamination: Dust, moisture, or conductive debris across terminal blocks can cause false triggering (especially in non-wetting configurations).

- Backplane connector corrosion: Intermittent communication with the TDC controller results in “flickering” input states.

- Loss of wetting voltage (if applicable): Internal DC bias supply fails, rendering dry-contact field devices unreadable.

A critical limitation is the absence of diagnostics. Unlike modern DI modules that detect open wires or short circuits, this module provides no feedback—making faults invisible until they cause an operational incident.

Recommended maintenance practices:

- Perform annual contact loop verification: simulate each input and confirm DCS response

- Inspect terminal blocks for corrosion, loose wires, or carbon tracking

- Use a multimeter to verify wetting voltage (if present) during outages

- Power-test spare modules for ≥48 hours under simulated field conditions before deployment

HONEYWELL 05701-A-0361

Lifecycle Status and Migration Strategy

Honeywell ceased all support for the TDC 2000 platform decades ago. The 05701-A-0361 is fully obsolete, with no path for repair, replacement, or technical assistance from the OEM. Continued use contradicts modern functional safety standards (e.g., IEC 61511), which require diagnostic coverage and proof testability—neither possible with this hardware.

Short-term mitigation:

- Maintain a pool of burn-in-tested spares

- Implement external supervision relays or PLC-based shadow monitoring (adds complexity and cost)

- Increase frequency of manual proof tests

Long-term strategic path: Migrate to Honeywell Experion PKS or ControlEdge Universal I/O. Benefits include:

- Intelligent DI modules with built-in open-wire detection and LED status

- Reuse of existing field wiring via terminal adapters

- Integration with asset management for automated diagnostics and compliance reporting

- Cybersecurity features aligned with IEC 62443

Migration requires re-engineering logic narratives, updating electrical drawings, and revalidating safety functions—but eliminates obsolescence exposure and significantly enhances operational reliability. Given the safety-critical role of digital inputs, facilities still operating TDC 2000 should treat migration as an urgent risk-reduction priority.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: