Description

Key Technical Specifications (For Spare Parts Verification)

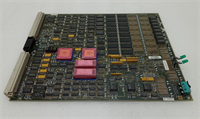

- Product Model: 05701-A-0351

- Manufacturer: Honeywell

- System Family: TDC 2000 (Total Distributed Control)

- Module Type: Low-Level Analog Input (LLAI)

- Input Channels: 16 differential inputs

- Supported Sensor Types: Thermocouples (J, K, E, T, R, S), RTDs (Pt100, Ni120), and ±100 mV DC signals

- Cold Junction Compensation: Integrated for thermocouple inputs

- Resolution: 14-bit effective A/D conversion

- Accuracy: Typically ±0.25% of span (dependent on sensor type and ambient conditions)

- Isolation: Channel-to-backplane isolation (approx. 500 VDC); no channel-to-channel isolation

- Update Rate: ~100–200 ms per channel (system load dependent)

- Configuration: Set via internal DIP switches and jumpers for sensor type per channel

- Mounting: Requires TDC 2000 I/O chassis with compatible power and data backplane

- Power Consumption: ~9–12 W (supplied via TDC backplane)

System Positioning and Downtime Impact

The Honeywell 05701-A-0351 is a specialized I/O module used extensively in TDC 2000 systems for direct temperature measurement in applications such as steam turbines, chemical reactors, fired heaters, and compressor bearings. By eliminating the need for external temperature transmitters, it reduced installation cost and complexity in its era—but also centralized risk in a single point of failure.

This module typically feeds data to regulatory control loops (e.g., superheat temperature control) or safety functions (e.g., high-bearing-temperature trip). If it fails—due to internal component drift, power anomaly, or connector fault—it may output fixed, erratic, or invalid values. In many legacy configurations, such failures can trigger nuisance alarms, force manual operation, or—more critically—cause a safety system to miss a genuine overtemperature event. In continuous-process facilities still running TDC 2000, this poses both operational and compliance risks under standards like IEC 61511.

Reliability Analysis and Common Failure Modes

Although robustly engineered, the 05701-A-0351 is now well beyond its intended service life. The most frequent failure mode is drift in the precision instrumentation amplifiers and reference voltage circuits, leading to inaccurate temperature readings—often undetected until calibration reveals offsets of several degrees. Electrolytic capacitors in the local power supply section degrade over time, causing intermittent resets or complete loss of communication with the TDC controller. Additionally, the terminal blocks and backplane connectors are susceptible to corrosion, especially in high-humidity environments, resulting in open circuits or noisy signals.

A notable design limitation is the absence of per-channel diagnostics or self-calibration. Unlike modern temperature I/O modules, it cannot report sensor health (e.g., open RTD) or compensate for long-term drift—making preventive verification essential.

Recommended maintenance actions include:

- Performing annual calibration using certified temperature simulators across multiple ranges

- Inspecting terminal connections for oxidation or mechanical looseness

- Verifying DIP switch settings against as-built documentation

- Powering spare modules in a test rack for at least 72 hours to uncover latent thermal or timing faults

HONEYWELL 05701-A-0351

Lifecycle Status and Migration Strategy

Honeywell officially ended support for the TDC 2000 platform decades ago, with the 05701-A-0351 classified as obsolete since the early 2000s. No new units exist, OEM repairs are unavailable, and technical documentation is no longer distributed. Continued reliance on this hardware exposes facilities to increasing operational, safety, and cybersecurity vulnerabilities.

As an interim measure, organizations may procure tested surplus modules or use third-party services that refurbish units by replacing aging capacitors and recalibrating signal paths. However, these are short-term fixes with diminishing returns.

The strategic path forward is migration to Honeywell Experion PKS or ControlEdge Universal I/O platforms. Honeywell offers structured migration programs that include:

- Reuse of existing field wiring via terminal block adapters

- Automated conversion of basic analog tags and alarm logic

- Modern temperature I/O modules with built-in diagnostics, HART support, and cybersecurity features

Full migration requires revalidation of safety instrumented functions, updated operator graphics, and staff retraining—but delivers long-term sustainability, improved accuracy, and alignment with current industrial security frameworks (e.g., IEC 62443). Given the age of remaining TDC 2000 installations, initiating a formal migration feasibility study is strongly advised.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: