Description

Key Technical Specifications (For Spare Parts Verification)

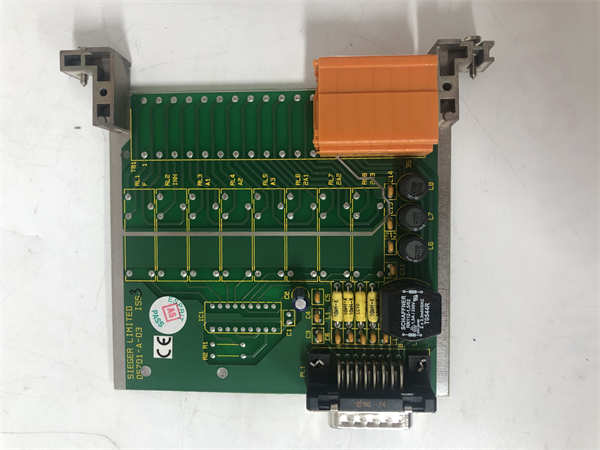

- Product Model: 05701-A-0326

- Manufacturer: Honeywell

- System Family: TDC 2000 (Total Distributed Control)

- Module Type: Digital Output (DO)

- Output Channels: 16 isolated discrete outputs

- Output Type: Typically electromechanical relays (Form A or Form C, depending on revision) or opto-isolated transistor drivers (verify by suffix or label)

- Contact Rating: Commonly rated for 2 A @ 30 VDC or 250 VAC (relay type); solid-state variants limited to lower current

- Isolation: Channel-to-backplane isolation (typically 500–1000 VDC)

- Response Time: <10 ms typical for solid-state; <15 ms for relay-based outputs

- Power Source: Field power typically supplied externally via terminal blocks (not backplane-powered)

- Mounting: Requires TDC 2000 I/O chassis with compatible data and power backplane

- Configuration: Fixed function; no software configuration—output state driven by TDC controller logic

- Diagnostic Capability: None – no feedback on output status or relay health

System Positioning and Downtime Impact

The Honeywell 05701-A-0326 serves as a critical actuation interface in legacy TDC 2000 systems deployed in refineries, chemical plants, and power generation facilities. It translates logical commands from the DCS into physical actions—such as opening a blowdown valve during overpressure, starting a lube oil pump on low pressure, or activating an alarm horn. Because these outputs often feed directly into safety or regulatory control loops, a failed module can result in failure to actuate during a real event, potentially leading to equipment damage, environmental release, or personnel hazard.

In many older installations, redundancy was not implemented at the I/O level, making this single module a single point of failure. A malfunction may go unnoticed until a demand occurs—highlighting the importance of proactive testing and spare availability.

Reliability Analysis and Common Failure Modes

Despite its rugged design, the 05701-A-0326 is now highly susceptible to age-related degradation. The most common failure mode depends on output type:

- Relay-based versions: Contact oxidation, coil burnout, or mechanical fatigue after decades of inactivity. Relays that rarely cycle are especially prone to “sticking” due to sulfidation or moisture ingress.

- Solid-state versions: Degradation of optocouplers or output transistors, leading to open-circuit or shorted outputs.

Additional risks include:

- Cracked solder joints on high-current traces due to thermal cycling

- Corrosion in terminal blocks causing high resistance or open circuits

- Backplane connector wear leading to intermittent communication with the TDC controller

Critically, the module provides no diagnostic feedback—the DCS cannot confirm whether a commanded output actually energized a field device. This “blind actuation” increases latent risk.

Recommended maintenance practices:

- Perform functional loop checks annually: command each output and verify field device response

- Measure contact resistance on relay outputs during outages (should be <100 mΩ)

- Inspect terminal blocks for discoloration, looseness, or arcing

- Store spares in climate-controlled conditions and perform 72-hour powered burn-in before deployment

HONEYWELL 05701-A-0326

Lifecycle Status and Migration Strategy

Honeywell discontinued the TDC 2000 platform in the late 1990s, and the 05701-A-0326 has been obsolete for decades. No OEM support, repairs, or replacement parts are available. Continuing to operate this hardware violates modern functional safety best practices (e.g., IEC 61511 requires diagnostic coverage and proof test intervals—neither feasible with this module).

Short-term mitigation includes:

- Sourcing and fully testing surplus modules

- Implementing external watchdog relays or contact supervision circuits (adds complexity)

- Maintaining rigorous manual proof testing schedules

However, the only sustainable solution is migration to a modern DCS such as Honeywell Experion PKS or ControlEdge UOC. Honeywell’s migration path supports:

- Reuse of existing field wiring via adapter terminal blocks

- Replacement with intelligent digital output modules featuring built-in diagnostics, fuse monitoring, and electronic short-circuit protection

- Integration with asset management systems for automated proof testing

Migration requires re-engineering logic, updating electrical schematics, and revalidating safety functions—but eliminates obsolescence risk and aligns the facility with current cybersecurity (IEC 62443) and safety lifecycle standards. Given the critical role of digital outputs in process safety, organizations should prioritize this upgrade as part of their long-term asset integrity strategy.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: