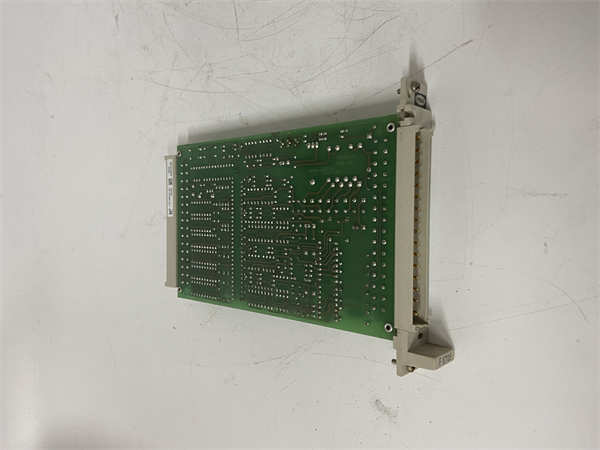

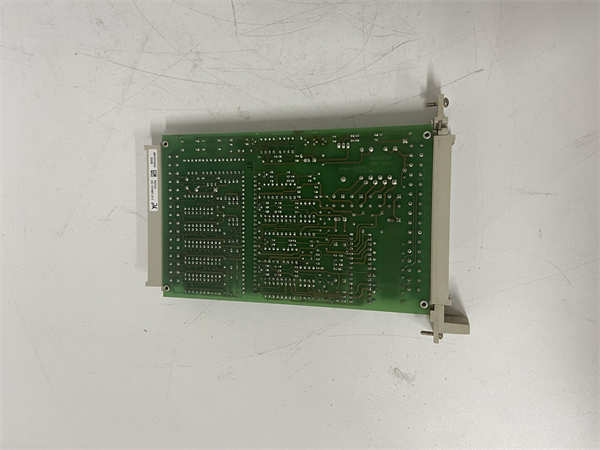

Description

Key Technical Specifications (For Spare Parts Verification)

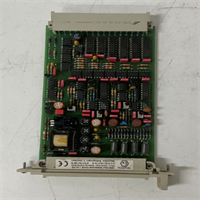

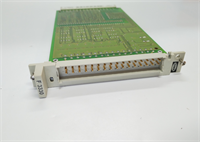

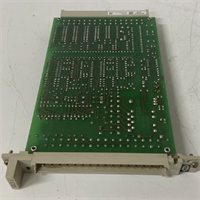

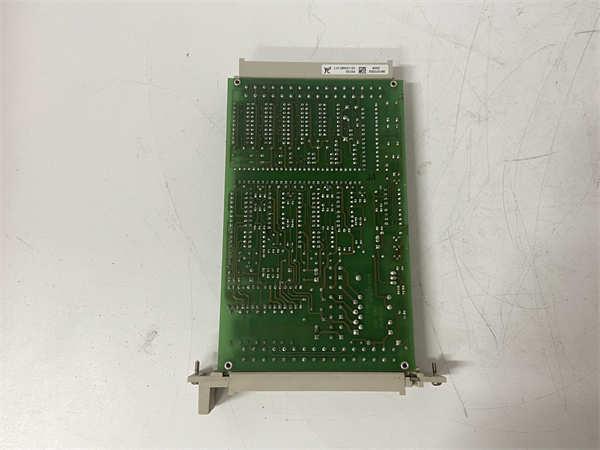

- Product Model: F6705

- Manufacturer: HIMA

- System Family: H51q / HIMax Safety Controller Platform

- Output Channels: 4 isolated, fail-safe analog outputs

- Output Signal: 4–20 mA (sink or source mode, depending on configuration)

- Load Capability: Up to 750 Ω per channel

- Diagnostic Features: Continuous loop monitoring (open-circuit, short-circuit, out-of-range detection), internal self-test

- Redundancy Support: Designed for use in 1oo2 or 2oo3 redundant configurations

- Certification: Certified to IEC 61508 SIL 3, IEC 61511, ATEX, FM

- Power Supply: Via redundant backplane from H51q/HIMax chassis

- Form Factor: Standard HIMA module (fits H51q and early HIMax racks)

- Operating Temperature: 0°C to +60°C

System Role and Downtime Impact

The F6705 is typically deployed in high-integrity safety applications such as emergency blowdown valves in oil & gas, reactor cooling control in chemical plants, or turbine bypass systems in power generation. It receives trip commands from the safety logic solver and converts them into precise analog signals to modulate final elements—often overriding normal process control during hazardous events.

A failure of the F6705 can lead to two critical scenarios:

- Fail-dangerous: Output remains at “normal” value during a required trip, preventing valve closure or drive ramp-down—potentially escalating a hazard

- Fail-safe: Output defaults to 0 mA or fault state, causing an unnecessary but safe shutdown—resulting in production loss

Because it directly influences the physical state of safety equipment, the F6705 is classified as a safety-critical component under IEC 61511. Its malfunction can invalidate the entire safety instrumented function (SIF), exposing facilities to regulatory non-compliance and operational risk.

Reliability Analysis and Common Failure Modes

Despite robust design, aging F6705 modules are susceptible to several degradation mechanisms after prolonged service:

- Output driver IC drift: The precision current-output amplifiers degrade over time, causing gain/offset errors that push signals outside acceptable tolerances.

- Internal reference voltage instability: Aging of voltage references affects output accuracy, especially under temperature fluctuations.

- Backplane connector corrosion: Oxidation on power or data pins leads to intermittent communication or undervoltage faults.

- Capacitor leakage in filtering circuits: Compromises signal stability and increases susceptibility to EMI-induced noise.

Design vulnerabilities include limited tolerance for external loop impedance changes and sensitivity to ground potential differences in long cable runs. For preventive maintenance, technicians should:

- Conduct annual loop calibration using certified mA sources and record deviation trends

- Monitor HIMA diagnostic logs for “AO Fault,” “Range Violation,” or “Loop Open” events

- Verify terminal tightness and shield grounding during scheduled outages

- Ensure ambient cabinet temperature remains stable to minimize thermal stress

HIMA F6705

Lifecycle Status and Migration Strategy

HIMA has discontinued the F6705 as part of its transition away from the H51q platform toward the HIMax X and SMART Safety architectures. No new production exists, and official repair services are no longer offered outside legacy support agreements. Continued use introduces significant risks: inability to replace failed units promptly, loss of traceable calibration, and challenges in passing functional safety audits.

As an interim solution, facilities may:

- Procure only from HIMA-certified refurbishers who provide full loop simulation test reports

- Maintain a minimum of two fully tested spares per critical SIF

- Implement external analog watchdog relays to detect stuck-at values (subject to SIL validation)

For long-term sustainability, HIMA recommends migrating to the HIMax X platform, using modern equivalents such as the F-XAO4 analog output module. This upgrade path involves:

- Replacing the controller chassis and I/O modules

- Reusing existing field wiring where electrical compatibility is confirmed

- Revalidating all SIFs with updated PFD (probability of failure on demand) calculations

- Leveraging the PASmikro engineering suite for streamlined configuration and diagnostics

Given its direct role in actuating safety responses, the obsolescence of the F6705 demands urgent attention within any functional safety lifecycle management program. Delaying action increases both operational vulnerability and compliance exposure.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: