Description

Technical Specifications (For Spare Part Verification)

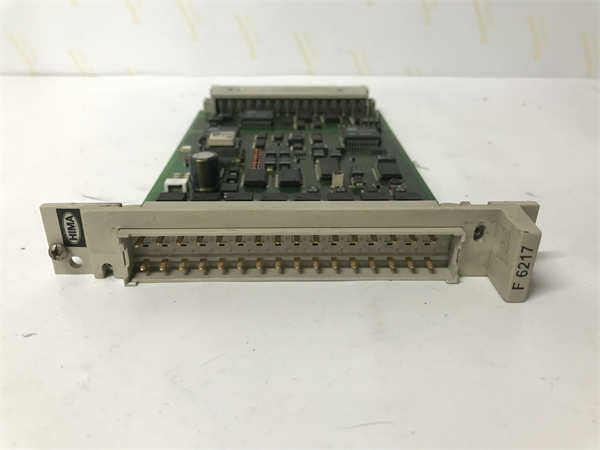

- Product Model: F6217

- Manufacturer: HIMA

- System Family: HIMax (original generation, not HIMax X)

- Output Channels: 4 isolated analog outputs

- Output Signal: 4–20 mA, loop-powered or externally powered

- Load Capability: Up to 750 Ω at 24 VDC

- Accuracy: ±0.1% of full scale

- Diagnostic Coverage: >95% per channel (includes open-circuit, short-circuit, and signal deviation detection)

- Safety Certification: Certified per IEC 61508 up to SIL 3

- Isolation: Channel-to-channel and channel-to-backplane isolation (≥500 VAC)

- Backplane Interface: Proprietary HIMax bus (requires F6xxx/F8xxx chassis and redundant power supply)

- LED Indicators: Power, OK, Fault, and per-channel status

- Operating Temperature: 0°C to +60°C

System Role and Downtime Impact

The HIMA F6217 serves as a vital output interface in legacy HIMax-based safety instrumented systems, commonly found in oil & gas, petrochemical, and power generation facilities. It translates safety logic decisions—such as “close emergency isolation valve” or “ramp down compressor speed”—into precise, certified analog commands sent to field devices. As a SIL 3 component, its correct operation is essential for functional safety integrity. If this module fails silently (e.g., output stuck at 12 mA), the final element may not respond during a hazardous event, leading to escalation of process upset, equipment damage, or personnel exposure. Unlike digital faults that often trigger alarms, analog output drift can go undetected without rigorous testing. In the absence of a verified spare, restoring safety function may require weeks of sourcing and validation, forcing prolonged operation under manual override—a high-risk state that compromises compliance with process safety management standards.

Reliability Analysis and Common Failure Modes

Although designed for high-reliability applications, the F6217 is prone to predictable wear mechanisms after 10–15 years of continuous service. The most common failure mode involves degradation of the precision current-output driver ICs and associated feedback resistors, leading to signal drift, nonlinearity, or complete channel dropout. Internal voltage references may also age, causing offset errors that fall outside the diagnostic window. Additionally, the terminal block connections are susceptible to thermal stress and vibration-induced loosening, resulting in intermittent output or increased contact resistance that affects loop performance.

Key design vulnerabilities include:

- No hot-swap capability—replacement requires partial or full rack shutdown

- Sensitivity to ground loops if field wiring shielding is improperly terminated

- Limited self-diagnostics for small-magnitude drifts (e.g., <2% error may not trigger fault)

Preventive maintenance recommendations:

- Perform annual loop calibration using a certified mA source/sink and verify response across full range

- Conduct proof tests by commanding 4 mA, 12 mA, and 20 mA and validating actuator position

- Inspect terminal torque and shield grounding during scheduled outages

- Store spares in ESD-safe, climate-controlled packaging with humidity indicators

HIMA F6217 984621702

Lifecycle Status and Migration Strategy

HIMA has discontinued the F6217 as part of the phased retirement of the original HIMax platform. Manufacturing has ceased, and factory-level technical support is no longer available. Remaining inventory consists of untested surplus or refurbished units with uncertain calibration history—posing unacceptable risk in safety-critical applications.

As an interim measure, facilities may:

- Acquire and fully functionally test one or more spares under simulated load conditions

- Implement external loop monitors to detect out-of-range or static output signals

- Enforce strict proof test protocols to catch early signs of degradation

For long-term sustainability, HIMA recommends migration to the HIMax X platform. The direct functional replacement is the F-XAO4 (part number 984865282), which offers:

- Enhanced accuracy (±0.05% F.S.) and wider load drive capability (up to 1000 Ω)

- Advanced diagnostics including live zero monitoring and predictive health indicators

- Hot-swap support and guaranteed lifecycle through 2035+

Migration typically involves:

- Replacing the HIMax controller and I/O chassis with HIMax X equivalents

- Adapting field wiring via terminal conversion kits or junction box retermination

- Recompiling safety application logic in PASconfig and revalidating all SIFs per IEC 61511

Executing this upgrade during planned turnaround periods eliminates obsolescence exposure while restoring full diagnostic coverage, ensuring continued operational safety and regulatory compliance.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: