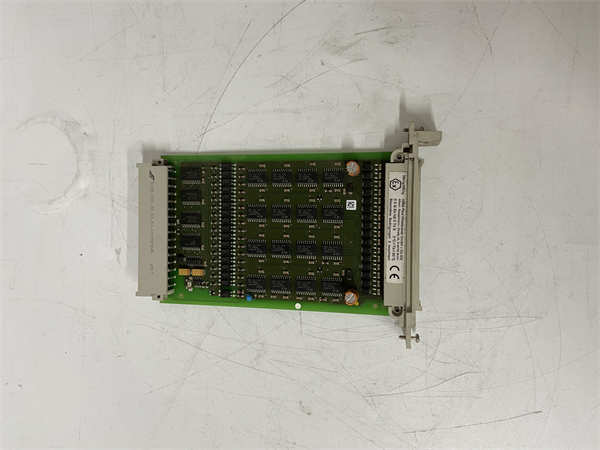

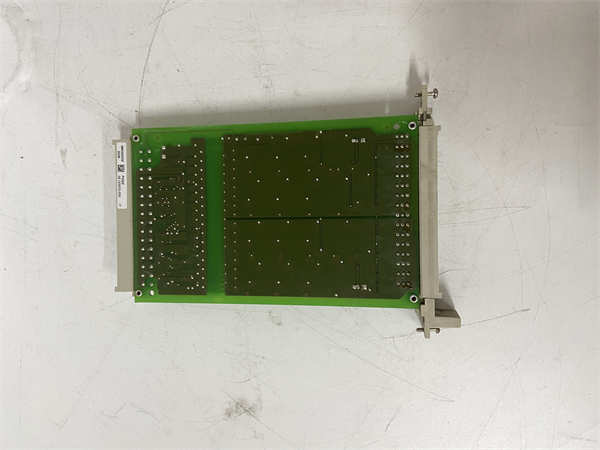

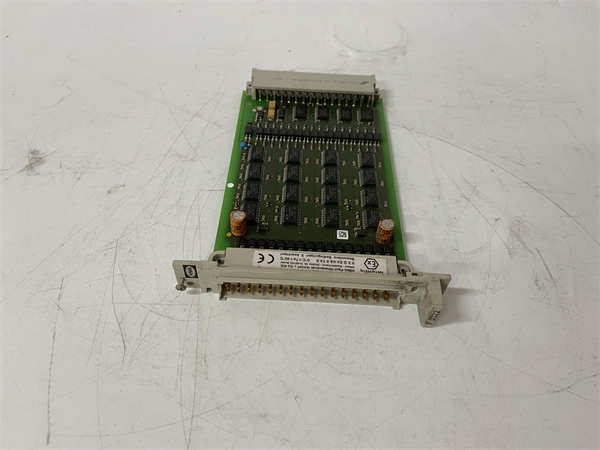

Description

Technical Specifications (For Spare Part Verification)

- Product Model: F3322

- Manufacturer: HIMA

- System Family: HIMatrix (legacy safety PLC platform, predecessor to HIMax)

- Output Channels: 4 isolated analog outputs

- Output Signal Type: 4–20 mA (standard), typically with HART compatibility

- Load Capability: Up to 750 Ω (at 24 VDC supply)

- Accuracy: ±0.1% of full scale

- Safety Certification: Certified per IEC 61508 up to SIL 3

- Diagnostic Coverage: >95% (includes open-circuit, short-circuit, and out-of-range detection)

- Isolation: Channel-to-channel and channel-to-backplane isolation (≥500 VAC)

- Backplane Interface: Proprietary HIMatrix bus (requires F3xxx series chassis and power supply)

- LED Indicators: Power, OK, Fault, and per-channel status

- Operating Temperature: 0°C to +60°C

System Role and Downtime Impact

The HIMA F3322 is a critical output interface in legacy HIMatrix-based safety systems, commonly deployed in chemical processing, oil & gas, and power generation facilities. It translates safety logic decisions—such as initiating a controlled blowdown or modulating a cooling water valve—into precise 4–20 mA signals for final elements. Unlike digital outputs that simply trip, analog outputs enable graded responses, which are essential in complex SIFs requiring proportional actuation. A failed F3322 may output zero current (failing safe but causing unnecessary shutdown) or lock at a fixed value (failing dangerously by preventing proper response). In either case, the loss of this module compromises the integrity of the entire SIF. Without a verified spare, recovery can take weeks, leaving the process unprotected or forcing operation under manual override—a high-risk scenario.

Reliability Analysis and Common Failure Modes

Despite its robust safety design, the F3322 is vulnerable to component aging after 15+ years of service. The most common failure mode involves degradation of the precision operational amplifiers and voltage-to-current conversion circuits, leading to output drift, nonlinearity, or complete channel dropout. Internal reference voltage sources can also drift over time, causing calibration shifts that fall outside acceptable tolerances. Additionally, the output protection diodes may degrade due to repeated exposure to inductive kickback from valve positioners, eventually failing short or open. Environmental factors like sustained high temperature accelerate semiconductor aging, while humidity can cause leakage currents on PCB traces.

Key design limitations include:

- No built-in loop-powered device diagnostics beyond basic current monitoring

- Sensitivity to ground loops if field wiring is not properly isolated

- Limited tolerance for reverse polarity or overvoltage on output terminals

Preventive maintenance recommendations:

- Perform annual functional tests by commanding defined output values (e.g., 4, 12, 20 mA) and verifying field device response

- Measure output accuracy and ripple using a calibrated milliamp meter during scheduled outages

- Inspect terminal blocks for signs of arcing, discoloration, or corrosion

- Store spares in anti-static, dry, temperature-controlled environments

HIMA F3322

Lifecycle Status and Migration Strategy

HIMA discontinued the F3322 as part of the broader retirement of the HIMatrix platform, which has been superseded by the HIMax and HIMax X families. Official manufacturing ceased years ago, and technical support is no longer available. Remaining units exist only in decommissioned systems or unverified surplus channels—posing significant risk due to unknown operational history and potential latent defects.

As a temporary measure, facilities may:

- Secure one or more fully tested spares with documented calibration certificates

- Implement external loop monitors to detect abnormal current levels or open circuits

- Minimize unnecessary output cycling to reduce stress on analog components

For long-term viability, HIMA recommends migration to the HIMax X platform. The equivalent analog output module is the F-XAO4, which provides:

- Higher accuracy (±0.05%) and enhanced diagnostics (including HART pass-through)

- Native support for PROFINET and OPC UA for integration with modern control and asset management systems

- Extended lifecycle support with guaranteed availability through at least 2035

Migration entails:

- Replacing the HIMatrix controller and I/O chassis with HIMax X hardware

- Rewiring analog outputs to new terminal bases (field cabling often reusable via junction boxes)

- Recompiling safety logic in PASconfig and revalidating all SIFs per IEC 61511

Executing this upgrade during planned maintenance windows eliminates obsolescence risk while restoring full diagnostic visibility and ensuring continued compliance with functional safety and operational reliability requirements.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: