Description

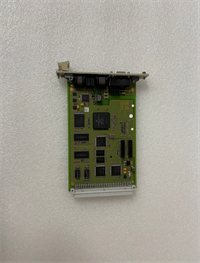

Key Technical Specifications (For Spare Part Verification)

- Product Model: F3221

- Order Number: 984322102

- Manufacturer: HIMA

- System Compatibility: HIMax Classic safety controller platform

- Input Channels: 16 galvanically isolated digital inputs

- Input Voltage Range: 20–30 VDC (nominal 24 VDC)

- Safety Certification: Certified per IEC 61508 up to SIL 3

- Diagnostic Coverage: >99% (including wire break, short circuit, and cross-wire detection)

- Redundancy Support: Compatible with 1oo2 and 2oo2 voting architectures

- Mounting: DIN rail mounted within standard HIMax chassis

- Front Indicators: Per-channel LED status (ON/OFF/FAULT) and module OK signal

- Backplane Interface: Proprietary high-speed bus for communication with F7130A or equivalent CPU

System Role and Downtime Impact

The F3221 module serves as a critical data acquisition layer in safety-critical applications such as emergency shutdown (ESD), fire & gas detection, and burner management systems. It continuously monitors the state of field-mounted safety switches and transmits validated signals to the central CPU (e.g., F7130A) for logic evaluation. Its diagnostic capabilities ensure that wiring faults—such as open circuits or short-to-ground—are detected and reported as safe failures, preventing dangerous undetected faults.

If this module fails or is improperly replaced, two high-risk scenarios may occur:

- Failure to detect a trip condition: A wire break goes unnoticed, and the system does not initiate shutdown during an overpressure event.

- Spurious trip: Internal fault causes false “active” signal, triggering an unplanned plant shutdown with significant financial impact.

In regulated industries, loss of input integrity can violate IEC 61511 requirements and invalidate the entire Safety Instrumented Function (SIF). Since the F3221 often interfaces with dozens of field devices, its reliability directly affects the proof test interval and overall risk profile of the installation.

Reliability Analysis and Common Failure Modes

Although built to stringent safety standards, the F3221 exhibits age-related vulnerabilities common to early-generation safety I/O modules. The most frequent failure mode is input optocoupler degradation, leading to reduced signal sensitivity—particularly under low-voltage or high-noise conditions. This may cause intermittent “chatter” or missed transitions that evade standard diagnostics.

Internal fuse fatigue on the power distribution path can result in partial channel loss without front-panel indication. Additionally, terminal block corrosion—especially in humid or corrosive environments—increases contact resistance, distorting input voltage levels and potentially triggering false wire-break alarms.

A key design limitation is the lack of field-replaceable components; any internal fault typically requires full module replacement. Units subjected to frequent electrical transients (e.g., from nearby motor starters) show accelerated wear on input clamping diodes.

Recommended preventive actions include:

- Conducting periodic functional tests that simulate both normal and faulted input conditions (e.g., wire break)

- Measuring input loop resistance and voltage at terminals during maintenance outages

- Verifying LED indicators match actual field device states

- Ensuring proper shielding and grounding of field cables to minimize EMI-induced errors

HIMA F3221 984322102

Lifecycle Status and Migration Strategy

HIMA has formally obsoleted the F3221 as part of its transition to the HIMax X platform. The module is no longer manufactured, and official repair or technical support is unavailable. Continued operation increases exposure to supply shortages, extended downtime, and challenges in passing functional safety audits.

Short-term risk controls include:

- Securing multiple tested spares with identical order numbers and revision levels

- Maintaining accurate wiring diagrams and I/O allocation records

- Validating module behavior in a test rack using representative field signals

For long-term sustainability, HIMA supports migration to the HIMax X-DI module (e.g., F8221), which provides:

- Full mechanical compatibility with existing HIMax chassis (via adapter rails)

- Enhanced diagnostics, higher channel density, and improved noise immunity

- Seamless integration with PASconfig X engineering environment

Migration typically involves:

- Reusing existing field wiring (with verification of voltage compatibility)

- Updating I/O configuration in the safety application

- Revalidating all associated SIFs per IEC 61511

For facilities managing multiple legacy SIS platforms, a modular, asset-based replacement plan—prioritizing modules in highest-consequence safety loops—ensures continued compliance, operational reliability, and access to manufacturer support beyond 2030.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: