Description

Technical Specifications (For Spare Part Verification)

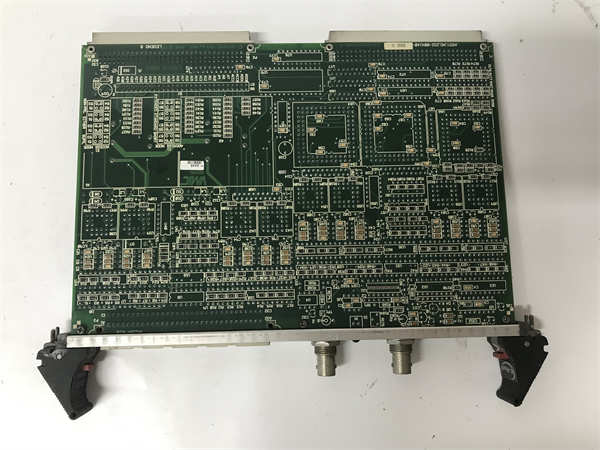

- Product Model: VMIVME-4140

- Manufacturer: GE Intelligent Platforms (acquired from VMIC)

- System Platform: VME64 / VME64x (VMEbus) embedded control systems

- I/O Configuration: 32 channels configurable as input or output (16 in / 16 out default)

- Isolation Voltage: 500 V RMS channel-to-channel and field-to-system

- Input Type: Dry contact or TTL-compatible (with pull-up)

- Output Type: Open-collector, sink up to 100 mA per channel

- Connector Type: Front-panel 100-pin SCSI-II (HD100)

- Operating Temperature: 0°C to +60°C (commercial grade)

- Form Factor: 6U VME (233.35 mm × 160 mm)

- Firmware/Revision: Hardware revisions (e.g., Rev A, B) are not backward-compatible in all applications—exact match required

System Role and Downtime Impact

The GE VMIVME-4140 serves as a primary discrete I/O interface in VME-based control systems deployed in power plants, test stands, and legacy military platforms. It typically resides in a 6U VME chassis alongside CPU boards (e.g., SBC618 or PP618) and other function modules. This board directly interfaces with field devices such as limit switches, solenoid valves, and alarm relays. Failure of the VMIVME-4140 can result in loss of critical input feedback or inability to actuate safety-related outputs. In turbine control or substation automation applications, this may trigger a full system trip or force a manual shutdown, leading to unplanned downtime that can cost tens of thousands of dollars per hour.

Reliability Analysis and Common Failure Modes

Despite its rugged design, the VMIVME-4140 is susceptible to age-related degradation due to its early-2000s manufacturing era. The most common failure modes include:

- Opto-isolator degradation: Over time, the internal optocouplers lose current transfer ratio (CTR), leading to intermittent signal dropout or complete channel failure, especially under high switching cycles.

- Connector and solder joint fatigue: Repeated thermal cycling causes micro-cracks in the HD100 front connector solder joints, resulting in flaky I/O behavior that is difficult to diagnose.

- Power rail capacitor aging: Although not equipped with a backup battery, the board relies on stable +5 V and ±12 V from the VME backplane; aging filter capacitors on older units can cause voltage droop under load, triggering spurious resets.

Key design weaknesses include reliance on through-hole components with limited surge protection on field lines and no built-in self-test (BIT) capability. As a maintenance best practice, technicians should:

- Perform annual continuity and isolation resistance tests on all channels using a calibrated megohmmeter.

- Inspect the HD100 connector for pin corrosion or bent contacts, particularly in humid environments.

- Monitor system logs for I/O scan errors that may indicate early opto-isolator failure before total channel loss occurs.

GE VMIVME-4140

Lifecycle Status and Migration Strategy

The VMIVME-4140 was officially declared obsolete by GE Intelligent Platforms (now part of Emerson) over a decade ago, with no direct replacement offered. Continued use carries significant risk: spare units are scarce, often sourced from decommissioned systems, and may have unknown operational history. Prices have risen sharply, and counterfeit or misrepresented units are increasingly common in the secondary market.

As a temporary mitigation, facilities can:

- Secure 1–2 verified-good spares through certified surplus channels with full functional test reports.

- Implement board-level repair programs focused on replacing opto-isolators and reflowing critical solder joints.

For long-term sustainability, migration is strongly advised. GE’s recommended path is transition to the VersaMax Nano or RX3i PACSystems platform, though this requires full application redevelopment. Alternatively, third-party VME-to-modern I/O gateways (e.g., using FPGA-based protocol converters) can extend system life while planning a phased control system modernization. Any migration project must include I/O mapping validation, timing analysis, and SIL reassessment if used in safety-critical roles.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: