Description

Technical Specifications (For Spare Part Verification)

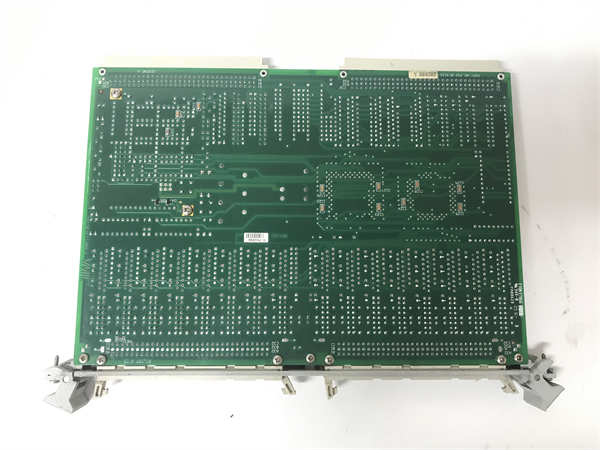

- Product Model: VMIVME-3122

- Manufacturer: GE Intelligent Platforms (acquired from VMIC)

- Bus Architecture: VME64 (VMEbus 6U form factor, 0.8″ pitch)

- I/O Configuration: 32 channels, software-configurable as input or output

- Isolation: Opto-isolated (2500 Vrms channel-to-bus isolation)

- Input Voltage Range: 5–32 VDC (sensed high/low threshold)

- Output Type: Open-collector, sink up to 100 mA per channel

- Operating Temperature: 0°C to +60°C (commercial grade)

- Firmware/Software Dependency: Requires VMI-specific drivers (e.g., VxWorks BSP or Windows NT/2000-era libraries)

- Physical Dimensions: 6U VME (233.35 mm × 160 mm), single-slot width

System Role and Downtime Impact

The GE VMIVME-3122 is typically deployed as a core I/O interface in embedded VME-based industrial control or automated test equipment (ATE) systems from the 1990s to early 2000s. It resides in a 6U VME chassis alongside CPU boards (e.g., PowerPC or Intel-based VME processors) and handles critical discrete signals—such as limit switch feedback, solenoid activation, or alarm status reporting. Because these systems were often custom-engineered for specific applications (e.g., power plant simulators, aerospace test rigs, or military ground stations), the VMIVME-3122 frequently serves as the only physical link between the controller and field devices. If this module fails and no spare is available, the entire system may become inoperable, leading to extended downtime in mission-critical or high-value testing environments.

Reliability Analysis and Common Failure Modes

Despite its robust opto-isolated design, the VMIVME-3122 exhibits predictable aging-related weaknesses common to electronics of its era. The most frequent failure mode involves degradation of the on-board electrolytic capacitors, particularly those in the local DC/DC converter circuit that powers the isolation barrier. Over time, these capacitors dry out, leading to voltage instability, intermittent I/O behavior, or complete loss of output drive capability. Additionally, the open-collector output transistors can be damaged by inductive kickback if field wiring lacks flyback diodes—a common oversight in older installations.

A key design vulnerability is the lack of on-board diagnostics; the module provides no health indicators or error flags, making fault isolation difficult without external probing. Furthermore, it relies on system-level software for configuration, so corruption of driver settings or memory maps can mimic hardware failure.

For preventive maintenance, technicians should:

- Inspect the board annually for bulging or leaking capacitors

- Verify output sink current capability under load using a calibrated test jig

- Ensure all field-side wiring includes suppression diodes for inductive loads

- Keep spare units powered periodically (every 6–12 months) to “reform” capacitors and prevent dielectric absorption issues

GE VMIVME-3122

Lifecycle Status and Migration Strategy

GE officially discontinued the VMIVME-3122 over a decade ago, with no direct replacement offered under the current Emerson portfolio. Continued use carries significant risk: spare availability is confined to brokers and surplus markets, authenticity cannot always be guaranteed, and technical support from the OEM is no longer available. Lead times can exceed 12 weeks, and counterfeit or previously failed units occasionally appear in circulation.

As an interim measure, organizations can pursue board-level repair through specialized third-party labs familiar with VME hardware, or stockpile tested spares while supply lasts. Some users implement external I/O relays driven by alternative VME modules (e.g., VMIVME-7750 with discrete daughter cards), though this adds complexity.

For long-term sustainability, migration to a modern platform is strongly advised. The recommended path is transition to a PCI/PCIe or CompactPCI-based I/O system (e.g., GE’s later cPCI-3122 equivalent, if compatible), or a complete shift to a contemporary industrial PC with Ethernet-based I/O (e.g., PROFINET or EtherCAT). This requires rewriting application software and re-architecting the backplane—but eliminates obsolescence risk and enables integration with modern SCADA and cybersecurity frameworks. A phased approach—running the legacy VME system in parallel with a new front-end during validation—is often the safest strategy for high-availability environments.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: