Description

Technical Specifications (For Spare Part Verification)

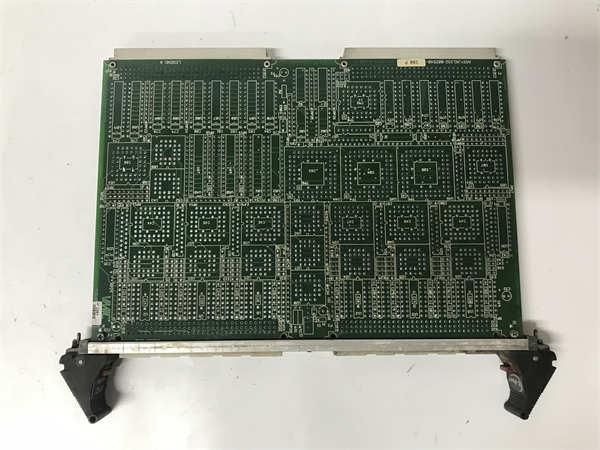

- Product Model: VMIVME-2540

- Manufacturer: GE Intelligent Platforms (acquired from VMIC)

- System Platform: VME64 / VME64x (VMEbus) embedded control systems

- Channel Count: 8 independent 32-bit counter/timer channels

- Input Type: TTL-compatible or differential RS-422 (via external conditioning)

- Maximum Input Frequency: 10 MHz per channel

- Time Base Accuracy: ±50 ppm (internal crystal), or external clock reference supported

- Connector Type: Front-panel 100-pin SCSI-II (HD100)

- Operating Temperature: 0°C to +60°C (commercial grade)

- Form Factor: 6U VME (233.35 mm × 160 mm)

- Firmware/Revision: Hardware revisions (e.g., Rev A vs. B) may differ in interrupt handling—exact match required for drop-in replacement

System Role and Downtime Impact

The GE VMIVME-2540 is typically deployed in VME-based control or data acquisition systems where precise measurement of rotational speed, flow rate, or event timing is critical. It commonly interfaces with turbine shaft encoders, generator tachometers, or calibration pulse trains in power generation and aerospace test facilities. The module converts high-frequency pulses into engineering units (e.g., RPM, Hz, or totalized counts) for use by the host CPU in closed-loop control or alarm logic.

Failure of this board directly compromises the integrity of speed or position feedback. In a gas turbine control system, loss of accurate RPM input can prevent safe startup or trigger a false overspeed trip. In hydroelectric plants, it may disable governor response during load changes. Because the VMIVME-2540 often supports safety-related or regulatory-compliant monitoring functions, its failure can result in forced derating or complete unit shutdown until restored—posing significant operational and compliance risk.

Reliability Analysis and Common Failure Modes

Although designed for industrial environments, the VMIVME-2540 is now well beyond its intended service life (typically manufactured between late 1990s and early 2000s). Common failure mechanisms include:

- Crystal oscillator drift or failure: The on-board time-base crystal degrades over time, causing inaccurate period/frequency measurements that manifest as erratic RPM readings.

- Input buffer IC degradation: High-voltage transients on field lines (even within spec) can slowly damage the front-end 74HC-series buffers, leading to intermittent signal dropout or complete channel loss.

- Connector and trace corrosion: In humid or high-sulfur environments (e.g., coastal power plants), the HD100 connector pins and PCB traces oxidize, increasing contact resistance and distorting fast edge signals.

A key design limitation is the lack of galvanic isolation on input channels—making the board vulnerable to ground loops and common-mode noise, which accelerates component stress. As part of preventive maintenance, users should:

- Periodically validate channel accuracy using a calibrated pulse generator across the full frequency range.

- Inspect the HD100 connector for tarnishing and clean with contact-safe solvent.

- Ensure proper shielding and grounding of field cabling to minimize EMI-induced errors that strain input circuits.

GE VMIVME-2540

Lifecycle Status and Migration Strategy

GE Intelligent Platforms (now part of Emerson) discontinued the VMIVME-2540 many years ago, with no direct functional successor in current product lines. No factory repair or calibration services are available. Continued reliance on this module introduces escalating risk: verified spares are extremely limited, and many available units have been salvaged from failed systems without burn-in testing.

Short-term mitigation options include:

- Acquiring 1–2 tested units from certified surplus vendors with full channel validation reports.

- Implementing external signal conditioning (e.g., isolated frequency-to-voltage converters) to reduce stress on aging inputs.

For sustainable operation, migration is necessary. While GE does not offer a pin-compatible VME replacement, viable paths include:

- Replacing the entire VME chassis with a modern PACSystems RX3i or VersaMax platform, using high-speed counter modules (e.g., IC695CMM002) — though this requires full application re-engineering.

- Deploying a third-party FPGA-based VME carrier that emulates the VMIVME-2540 register map while interfacing to modern I/O, enabling gradual transition without immediate software rewrite.

Any migration plan must include signal compatibility analysis, timing jitter evaluation, and recalibration of all dependent control loops to ensure functional equivalence.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: