Description

Technical Specifications (For Spare Part Verification)

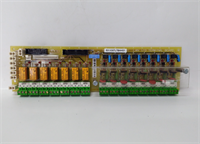

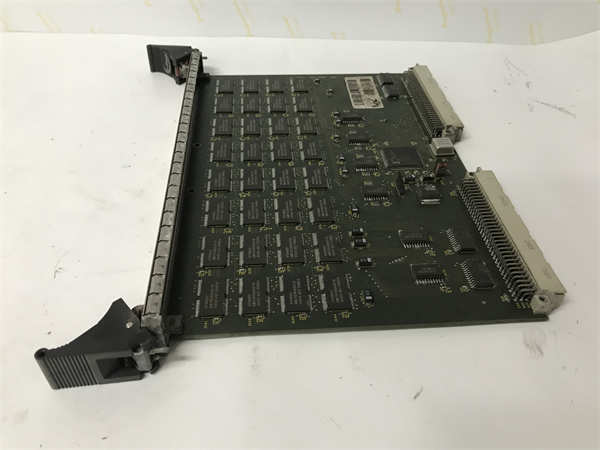

- Product Model: VMER-64

- Manufacturer: GE Intelligent Platforms (acquired from VMIC)

- System Platform: 6U VME64 / VME64x systems using compatible SBCs (e.g., SBC618, PP618)

- Form Factor: 6U VME RTM (Rear Transition Module), matches IEEE 1101.11 mechanical standard

- Connector Type: P2 backplane connector (VME P2) to rear-panel D-sub, SCSI, or custom I/O (design-dependent)

- Signal Routing: Passes through user-defined signals from SBC’s P2 pins (e.g., serial ports, GPIO, Ethernet, analog lines)

- Power Handling: Carries auxiliary power rails (+12 V, –12 V) from backplane to rear I/O if used by SBC

- Operating Temperature: 0°C to +60°C (commercial grade)

- Mechanical Keying: Specific keying posts to ensure compatibility only with designated SBC models

- Revision Sensitivity: Hardware revisions (e.g., Rev A vs. B) may differ in pin assignments—exact match required

System Role and Downtime Impact

The GE VMER-64 is not a standalone processing unit but a critical mechanical and electrical adapter that enables true 6U VME functionality. It mounts directly behind a compatible single-board computer (SBC) in a VME chassis and connects to the SBC’s P2 connector, routing selected signals to ruggedized rear-panel connectors. This architecture is common in power plant control, military test equipment, and industrial data acquisition systems where front-panel access is restricted and rear I/O is required for cabling discipline.

Failure or absence of a compatible VMER-64 renders the SBC unable to communicate with external devices—even if the CPU is fully operational. For example, if the VMER-64 carries serial ports to a turbine controller or Ethernet to a historian, its malfunction severs all external communication. In such cases, the entire VME subsystem becomes isolated, typically triggering a system fault or forcing manual intervention. Because the VMER-64 is mechanically and electrically paired to a specific SBC model, substitution with a generic RTM is not feasible without rewiring and revalidation.

Reliability Analysis and Common Failure Modes

While passive in design (no active components in most variants), the VMER-64 is vulnerable to mechanical and environmental stress due to its role as a signal conduit:

- P2 connector wear and misalignment: Repeated insertion/removal of the SBC can deform the RTM’s P2 socket contacts, leading to intermittent signal loss—especially on high-speed lines like Ethernet or clock signals.

- Rear connector solder joint fatigue: Vibration in industrial environments causes micro-cracks at the rear D-sub or SCSI connector solder joints, resulting in open circuits that mimic field device failures.

- Contamination and corrosion: Dust, oil, or humidity ingress into unsealed rear connectors leads to oxidation, increasing contact resistance and distorting digital waveforms.

A key design limitation is the lack of signal conditioning or protection—any surge or ESD event on field wiring propagates directly to the SBC through the VMER-64. As part of preventive maintenance, users should:

- Inspect P2 mating surfaces for bent pins or debris before SBC installation.

- Torque-check rear connector mounting screws annually to prevent loosening.

- Use conformal coating or sealed gland plates on rear I/O in harsh environments.

GE VMER-64

Lifecycle Status and Migration Strategy

GE Intelligent Platforms discontinued the VMER-64 series over 15 years ago, with no direct replacement in current product lines. The module is now considered a legacy interconnect component with zero factory support. Spare units are exceptionally rare, and many available listings misrepresent compatibility—claiming “fits all 6U VME” when pinouts are SBC-specific.

Short-term risk mitigation includes:

- Securing one verified-compatible spare per SBC type in use, tested as a matched pair.

- Creating a mechanical template to verify keying and connector alignment before purchase.

Long-term, migration away from VME is the only sustainable path. Modern alternatives include:

- Transitioning to CompactPCI Serial or VPX platforms with integrated rear I/O.

- Replacing the entire VME system with a PACSystems RX3i or industrial PC using PCIe-based I/O, though this requires full application redevelopment.

Because the VMER-64 is tightly coupled to its SBC, any upgrade must address both the processor and its rear I/O strategy simultaneously. Facilities should conduct a full I/O inventory and signal mapping exercise before initiating migration to avoid unexpected integration gaps.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: