Description

Technical Specifications (For Spare Part Verification)

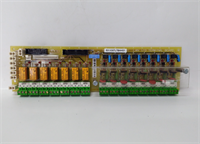

- Product Model: V7768-322001

- Manufacturer: General Electric (GE Power / GE Vernova)

- Product Family: Mark VIe I/O Packs (V7768 Series)

- Module Type: Mixed discrete I/O – 16 digital inputs, 16 digital outputs

- Input Type: Sourcing (24 V DC referenced to common return)

- Input Voltage Range: 18–32 V DC

- Output Type: Sourcing, short-circuit protected

- Output Current per Channel: Up to 500 mA

- Isolation: Optocoupler-based channel isolation; field-to-system isolation rated per IEC standards

- Communication: Dual-redundant Fault Tolerant Ethernet (FTE) to Mark VIe controllers

- Diagnostics: Per-channel LED status indicators, online self-test, fault logging via ToolboxST software

- Power: Supplied via backplane from Mark VIe I/O terminal board (e.g., V7768-TB322)

- Operating Temperature: 0°C to +60°C ambient

- Compliance: CE, UL, IEC 61508 (SIL2 capable in certified system architecture)

System Role and Downtime Impact

The V7768-322001 is a foundational I/O interface in GE Mark VIe control systems deployed on gas turbines, steam turbines, and compressors in power plants and industrial facilities. It directly connects the controller to hardwired field instrumentation—such as lube oil pressure switches, fuel valve position sensors, and emergency shutdown solenoids. While the Mark VIe architecture supports controller redundancy, many I/O packs like this one are installed without redundant counterparts due to original design constraints or cost considerations. A failure can prevent turbine startup (e.g., missing a “permissive” signal), disable a critical trip function (e.g., inability to energize a vent valve during overspeed), or cause nuisance trips due to false input states. In baseload generation, such an event can result in forced outages lasting multiple days, with financial impact often exceeding $ 500,000 per day in lost revenue and restart costs.

Reliability Analysis and Common Failure Modes

Despite its rugged industrial design, the V7768-322001 is vulnerable to several age- and environment-related failure mechanisms. The most prevalent issue is output driver damage caused by inductive kickback from unshielded or improperly suppressed solenoid coils in the field wiring—especially when flyback diodes degrade or were never installed. Input channels may become unresponsive due to optocoupler aging, particularly in units exposed to sustained high temperatures (>50°C) inside poorly ventilated I/O enclosures. Corrosion at the spring-cage terminal blocks (from humidity or chemical exposure in coastal or industrial sites) leads to high-resistance connections that mimic open-circuit faults. Additionally, repeated thermal cycling can induce micro-cracks in solder joints on high-current traces, causing intermittent behavior that is difficult to diagnose. As part of a preventive maintenance program, operators should verify the presence and condition of suppression components on all inductive loads, inspect terminal torque annually, and use GE’s ToolboxST software to monitor channel error counters and diagnostic logs. Units held in storage should be powered periodically to maintain electrolytic capacitor health and firmware integrity.

V7768-322001 GE

Lifecycle Status and Migration Strategy

GE has discontinued the V7768-322001 in favor of enhanced I/O packs with higher density, improved diagnostics, and better integration with modern Mark VIe firmware (e.g., V7768-324001 for 32 inputs or V7768-422001 with HART support). While GE continues to provide limited legacy support, new production has ceased, and future software updates may reduce compatibility. Short-term risk mitigation includes strategic procurement of tested spares, implementation of external relay buffering to protect output stages, and rigorous documentation of terminal wiring for rapid replacement. For long-term sustainability, GE recommends migrating to current-generation I/O hardware during planned outages—a process that requires re-engineering terminal block assignments, updating I/O tag databases in the control application, and revalidating all safety-critical interlocks. Third-party solutions, such as protocol-emulating I/O gateways, exist but introduce latency and reduce diagnostic visibility, making them unsuitable for high-integrity applications. A formal lifecycle review with GE or an authorized system integrator is advised to evaluate migration feasibility, cost, and operational impact before committing to a path forward.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: