Description

Technical Specifications (For Spare Part Verification)

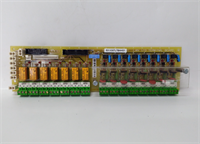

- Product Model: V7768-320000 (also labeled as 350-9301007768-320000 A0)

- Manufacturer: Bently Nevada (acquired by GE, now part of Baker Hughes)

- System Platform: 3500 Machinery Protection System

- Module Type: 3500/42M Dual-Channel Monitor

- Input Channels: 2 independent channels for Bently Nevada proximity probes (typically -24 V DC powered)

- Measurement Types: Radial vibration (displacement), axial position (thrust), or differential expansion

- Signal Conditioning: Onboard filtering, gap voltage monitoring, and dynamic range scaling

- Alarm/Trip Logic: Configurable high/low alarms and trips per channel with time delays and voting options

- Output Interface: Communicates status to 3500/55 relay modules via backplane; no direct relay outputs

- Power Source: +5 V and ±15 V from 3500 chassis backplane

- Diagnostic Features: Front-panel LEDs for OK, ALERT, DANGER, and configuration status

- Firmware/Configuration: Requires 3500 Rack Configuration Software (RCS) for setup; configuration stored in non-volatile memory

- Compliance: Designed to meet API 670 (5th Edition) requirements for machinery protection

System Role and Downtime Impact

The V7768-320000 (3500/42M) is a foundational component in Bently Nevada 3500-based machinery protection systems deployed across power generation, oil & gas, and petrochemical facilities. It directly interfaces with eddy-current proximity probes mounted on critical turbomachinery to continuously measure shaft vibration or position. The module processes these analog signals in real time and, upon detecting out-of-tolerance conditions, sends trip commands to output modules (e.g., 3500/55) that initiate emergency shutdowns. If this monitor fails—due to internal fault, configuration loss, or power anomaly—the protection layer for that machine segment is compromised. In a worst-case scenario, excessive vibration could go undetected, leading to bearing seizure, rotor rub, or catastrophic failure requiring months of repair and millions in lost production. Even partial failure (e.g., one channel down) may force derating or manual monitoring, increasing operational risk.

Reliability Analysis and Common Failure Modes

Despite its rugged industrial design, the V7768-320000 is susceptible to age-related degradation due to its dense analog circuitry and reliance on precision components. The most common failure modes include:

- Capacitor aging: Electrolytic capacitors on the power regulation section degrade over time, causing voltage instability, intermittent resets, or complete power-on failure.

- Probe driver circuit failure: The -24 V DC constant-current source for proximity probes can drift or fail, resulting in “GAP ERROR” or erratic vibration readings.

- Configuration memory corruption: Caused by power cycling without proper shutdown or exposure to electromagnetic interference, leading to loss of alarm thresholds or logic settings.

- Backplane connector fatigue: Repeated thermal cycling can cause micro-cracks in solder joints at the DIN connector, creating intermittent communication with the rack.

A key design vulnerability is the lack of redundant sensing on a single module—each channel is independent, but there is no cross-channel validation. Preventive maintenance should include periodic verification of gap voltage, inspection of front-panel LEDs for error states, cleaning of ventilation slots, and backup of RCS configuration files. Avoiding hot insertion/removal also reduces mechanical stress on connectors.

V7768-320000 350-9301007768-320000 A0 GE

Lifecycle Status and Migration Strategy

GE/Baker Hughes has officially discontinued the 3500/42M module family, including the V7768-320000, with no direct drop-in replacement available. Continued operation carries substantial risk: authentic spares are scarce, counterfeit units have appeared in the secondary market, and engineering support is limited to archived documentation. As an interim measure, users may source units from certified refurbishers with full functional test reports or implement board-level repairs—but these do not address long-term obsolescence.

The recommended migration path is a phased upgrade to the Bently Nevada 3500/42R (if still available in limited stock) or, more sustainably, to the System 1 platform with 3500/42E Enhanced Monitors, which offer improved diagnostics, cybersecurity features, and extended lifecycle support. This transition requires re-validation of all alarm/trip setpoints, potential rewiring of probe connections, and requalification under API 670. For new installations, the Orbit 60 series is the strategic successor. Given the critical safety role of this module, migration planning should be prioritized during the next major plant turnaround to avoid forced outages due to sudden hardware failure.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: