Description

Key Technical Specifications (For Spare Parts Verification)

- Product Model: SD-98762

- Manufacturer: General Electric (GE Power / GE Digital)

- System Platform: GE Speedtronic Mark V (used in gas and steam turbine control, primarily 1980s–2000s)

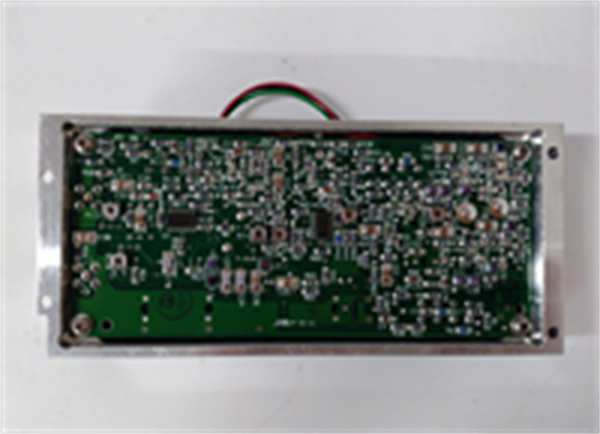

- Module Type: Passive terminal assembly or active I/O interface (exact function varies by revision; commonly a terminal card for analog inputs)

- Connector Type: Screw terminals or DIN 41612 backplane connector (depending on sub-variant)

- Compatible Racks: Typically mounts in Mark V I/O compartments (e.g., core rack or remote I/O cabinets)

- Signal Types Supported: Often associated with 4–20 mA, thermocouple, or RTD inputs; may also handle relay outputs

- Physical Dimensions: Approx. 160 mm (H) × 35 mm (W) – standard Mark V card size

- Labeling Requirement: Must include “SD-98762” and revision code (e.g., Rev A, B); absence suggests non-original replacement

- Mounting: Vertical card guide with retention clip in Mark V chassis

System Role and Downtime Impact

The SD-98762 is a foundational component in GE Mark V turbine control systems, which remain in service across global power plants, oil & gas facilities, and industrial cogeneration sites. While not always an active electronic module, it frequently provides the critical wiring interface that connects field instrumentation—such as exhaust temperature thermocouples, bearing vibration sensors, or fuel valve position feedback—to the Mark V’s triple-modular redundant (TMR) controllers. If this module fails due to mechanical damage, terminal corrosion, or backplane misalignment, the associated control loop becomes inoperable. In safety-critical applications, this can trigger turbine trip sequences, prevent startup, or force operation in degraded manual mode. Given the high cost of unscheduled outages in power generation (often exceeding $ 100,000 per hour), the unavailability of a verified SD-98762 spare directly impacts plant reliability and revenue.

Reliability Analysis and Common Failure Modes

Although many SD-98762 variants are passive terminal cards, they are still subject to environmental and mechanical degradation. The most common failure mode is terminal block corrosion caused by hydrogen sulfide, salt air, or humidity in turbine enclosures, leading to increased contact resistance and signal drift. Backplane connector pins can oxidize or bend over time, especially after repeated module swaps during maintenance, causing intermittent communication that mimics sensor faults. In active variants (if equipped with signal conditioning circuitry), electrolytic capacitors may dry out, resulting in noise or signal loss. Additionally, the card edge or plastic housing can become brittle due to prolonged heat exposure near turbine enclosures, cracking during handling.

Preventive maintenance should include:

- Annual inspection of terminal tightness and signs of discoloration or pitting

- Cleaning of backplane contacts with isopropyl alcohol and lint-free swabs

- Verification of signal integrity using calibrated test sources during outage windows

- Storage of spares in climate-controlled, anti-static packaging

GE SD-98762

Lifecycle Status and Migration Strategy

GE has long since discontinued the SD-98762 as part of the broader retirement of the Mark V platform, now superseded by Mark VIe and Mark VIeS. No new units are manufactured, and GE no longer provides repair services or technical support for this specific part number. Continued use carries significant risk: verified spares are increasingly rare, pricing is volatile, and counterfeit or mismatched revisions may cause system instability.

Short-term mitigation includes sourcing tested units from specialized obsolescence vendors, performing board-level cleaning and reconditioning, or consolidating unused modules from retired turbines. However, these are temporary measures.

GE’s strategic migration path is a full Mark V to Mark VIe upgrade, which replaces the entire control architecture with a modern, Ethernet-based, SIL-certified system. This transition involves:

- Replacing all I/O modules, terminal assemblies, and controllers

- Rewiring field connections to new terminal blocks (though conduit often reused)

- Converting control logic from Mark V application code to ToolboxST-based configuration

- Recertifying protection functions per IEC 61511

For facilities unable to justify full replacement, GE offers Life Extension Services including refurbished spares and third-party repair partnerships. Alternatively, some operators implement external signal duplication or bypass relays to isolate single-point failures. Until migration occurs, maintaining at least two verified SD-98762 modules—each inspected for mechanical integrity, terminal condition, and compatibility with the installed Mark V revision—is the only practical contingency to ensure rapid recovery during turbine control anomalies.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: