Description

Technical Specifications (For Spare Parts Verification)

- Product Model: IS230SNRTH2A

- Manufacturer: GE Power Conversion / GE Digital

- System Platform: Mark VIe Integrated Control System (for gas/steam turbines and compressors)

- Input Type: 16 channels of 3-wire RTD (Pt100 standard)

- Redundancy: Triple-modular redundant (TMR) capable; typically used in SRTC (Simplex) or TMR configurations

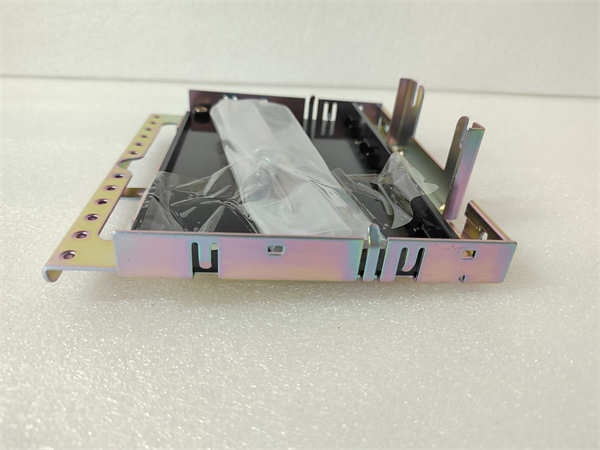

- Terminal Block: Screw-type field wiring terminals with removable connector

- Backplane Interface: Connects to VME-based I/O core (e.g., IS200VCRH1B or IS200VCMIH1C) via ribbon cable

- Diagnostic Features: Open-circuit and short-circuit detection per channel

- Operating Temperature: 0°C to +60°C (control room environment)

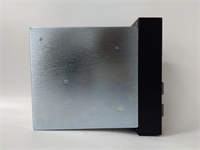

- Form Factor: Half-height I/O module, mounts on DIN rail within I/O chassis

System Role and Downtime Impact

The IS230SNRTH2A is a foundational sensor interface in GE’s Mark VIe turbine control architecture. It resides in the I/O compartment and directly connects to temperature sensors monitoring exhaust gas, bearing shells, lube oil, and compressor discharge. In a TMR-configured system, three identical modules operate in parallel for voting; in simplex systems, it is the sole source of temperature data. If this module fails—due to internal circuit fault, wiring issue, or loss of backplane communication—the control system may lose critical thermal protection logic. This can result in either an automatic turbine trip (causing unplanned downtime) or, worse, continued operation without thermal oversight, risking mechanical damage or safety incidents. Given its role in safety-critical loops, its reliability directly impacts plant availability and operational integrity.

Reliability Analysis and Common Failure Modes

Despite being obsolete, many IS230SNRTH2A modules remain in service due to the long lifecycle of heavy-duty turbines. However, age-related degradation is now a dominant concern. The most common failure modes include: electrolytic capacitor drying out on the PCB (leading to power instability), corrosion at terminal blocks from environmental moisture ingress, and intermittent ribbon cable connections due to repeated thermal cycling. A key design vulnerability is its reliance on stable +5V and ±15V backplane power; voltage sags or noise can cause erratic readings or module dropout. Additionally, the lack of onboard EEPROM means configuration is handled externally, but signal conditioning circuits are sensitive to ESD and ground loops.

For maintenance teams, proactive measures are essential: inspect terminal tightness annually, verify RTD loop resistance during outages, clean dust from ventilation slots in the I/O cabinet, and monitor diagnostic logs in ToolboxST for “RTD Fault” or “Channel Invalid” alarms. Keeping spare modules in climate-controlled storage (low humidity, no UV exposure) significantly extends their shelf life.

IS230SNRTH2A GE

Lifecycle Status and Migration Strategy

GE has officially discontinued the IS230SNRTH2A as part of the broader Mark VIe legacy component phase-out. Continued use carries significant risk: no new units are manufactured, existing stock is finite, and repair services are increasingly scarce. Prices on the secondary market have risen sharply, and counterfeit or misrepresented units are a growing concern.

As a temporary measure, facilities can pursue certified refurbished units with full functional test reports or engage specialized third-party repair vendors capable of component-level restoration (e.g., capacitor replacement, trace repair). However, these are stopgap solutions.

The strategic path forward is migration. GE recommends upgrading to the Mark VIeS or Mark VIe X platforms, where RTD inputs are handled by modern modules like the IS230SNRTD1A (non-redundant) or IS230SNRTT1A (TMR) within the newer I/O architecture. This transition requires hardware replacement, I/O re-mapping, and partial re-commissioning—but it restores access to factory support, cybersecurity updates, and long-term spare parts availability. For plants not ready for full controller replacement, a hybrid approach—retaining the Mark VIe CPU while replacing only failed I/O with verified surplus—can extend system life by 3–5 years, provided rigorous testing protocols are followed.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: