Description

Key Technical Specifications (For Spare Parts Verification)

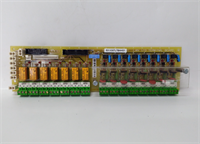

- Product Model: IS220PVIBH1A

- Manufacturer: GE

- System Family: Mark VIe integrated control and protection system (for gas/steam turbines)

- Input Channels: 4 differential dynamic inputs

- Supported Sensors: Proximity probes (e.g., Bently Nevada 3300 series), accelerometers, velocity transducers

- Input Range: Typically ±10 V full scale (configurable per channel)

- Signal Conditioning: Integrated oscillator-demodulator for eddy-current probes; AC/DC coupling options

- Sampling Rate: Sufficient for machinery protection (typically >1 kHz per channel)

- Output Interface: Backplane communication via Ethernet-based IONet to Mark VIe controllers

- Redundancy Support: Hot-swap capable in redundant I/O configurations

- Form Factor: 6U Eurocard, installed in IS200/IS220 I/O chassis

- Power: Supplied via backplane (±12 V, +5 V rails)

System Role and Downtime Impact

The IS220PVIBH1A is a foundational component in GE’s Mark VIe turbine control architecture, responsible for acquiring real-time vibration, shaft position, and differential expansion data from critical rotating equipment. This data feeds both the protection logic (e.g., high vibration trip) and the condition monitoring subsystem. A failure—whether total loss or signal drift—can cause nuisance trips or, more dangerously, mask developing mechanical faults. In combined-cycle power plants or industrial cogeneration facilities, an unplanned turbine trip results in immediate loss of generation, contractual penalties, and potential grid instability. Due to its role in safety-critical functions, this module is often deployed in redundant pairs, but single-unit failure still degrades system integrity and requires urgent replacement.

Reliability Analysis and Common Failure Modes

While designed for continuous operation in harsh environments, the IS220PVIBH1A exhibits age-related vulnerabilities:

- Degradation of precision analog components (op-amps, reference voltages) leading to signal offset or gain drift

- Failure of onboard DC/DC converters due to thermal stress, causing intermittent channel dropout

- Corrosion or fretting on backplane connectors, especially in high-humidity or high-vibration locations

- Damage to input protection circuits from ESD or transient surges during sensor maintenance

A notable design limitation is the lack of per-channel self-diagnostics for sensor health (e.g., open/cable fault detection beyond basic loop checks), making it difficult to distinguish between true machine issues and I/O faults. Additionally, the module relies on accurate probe gap calibration—if the analog front-end drifts, it may report false shaft positions.

Preventive actions include: periodic calibration against known signal sources, thermal imaging of installed modules to detect hot spots, verifying IONet communication status via ToolboxST, and inspecting sensor cabling for shielding integrity and ground loops.

Preventive actions include: periodic calibration against known signal sources, thermal imaging of installed modules to detect hot spots, verifying IONet communication status via ToolboxST, and inspecting sensor cabling for shielding integrity and ground loops.

GE IS220PVIBH1A

Lifecycle Status and Migration Strategy

GE has phased out the IS220 series as part of the broader transition toward the Mark VIeS and Mark VIe+ platforms, which integrate enhanced cybersecurity and higher-density I/O. While not all IS220 modules are formally declared obsolete in every region, the IS220PVIBH1A is no longer listed in current GE catalogs, and lead times for “new” units often reflect brokered inventory rather than factory stock. Official technical support is increasingly limited to extended service contracts.

Interim strategies include:

Interim strategies include:

- Maintaining a minimum of two verified spares per turbine

- Using third-party test fixtures to validate suspect modules before installation

- Implementing external vibration monitoring (e.g., Emerson AMS, PRUFTECHNIK) as a parallel safeguard

For long-term reliability, GE recommends upgrading to the IS220PDIAH1A (for digital proximity integration) or newer Mark VIe+ I/O modules with built-in diagnostics and improved noise immunity. However, such upgrades require firmware alignment, I/O re-mapping, and re-validation of protection setpoints—typically executed during major outages. Until then, disciplined asset management and condition-based sparing are essential to mitigate operational exposure.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: