Description

Technical Specifications (For Spare Parts Verification)

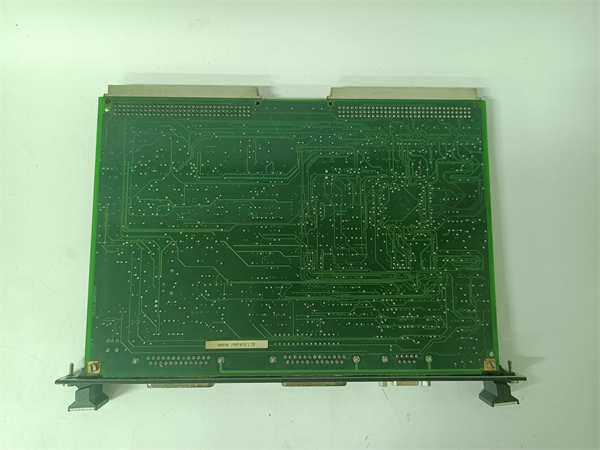

- Product Model: IS200ERIOH1AAA

- Manufacturer: GE Vernova

- System Family: Mark VI Turbine Control System

- Function: Remote I/O interface handler (ERIO = Extended Remote I/O)

- Communication Link: Proprietary high-speed serial or fiber-optic link to main VME-based controller (typically via VCMI or VME backplane)

- Supported I/O Types: Interfaces with terminal boards such as TERA, TBCA, TBSA for digital and analog signals

- Mounting: Installed in remote I/O rack, typically near field devices in turbine skid or auxiliary panels

- Power Supply: +24 VDC external supply; includes power monitoring circuitry

- Diagnostic Indicators: LEDs for POWER, COMM STATUS, FAULT, and MODULE OK

- Firmware Dependency: Must match the firmware version of the main controller and associated terminal boards

- Physical Connectors: Multi-pin DIN or ribbon cable interfaces for backplane and field wiring

GE IS200ERIOH1AAA

System Role and Downtime Impact

The IS200ERIOH1AAA enables the Mark VI system to distribute I/O beyond the main control cabinet—critical in large turbine installations where sensors and actuators are spread across the skid, lube oil console, or exhaust duct. It acts as a local “mini-controller,” scanning field signals and relaying data to the central VME rack via a deterministic communication link. If this module fails, all I/O in its remote rack becomes unavailable. Depending on the signals involved (e.g., flame detection, bearing temperature, valve feedback), the Mark VI logic may initiate a protective shutdown. In non-critical applications, the system might degrade to reduced functionality, but operator intervention is often required. Recovery involves replacing the module and verifying communication integrity—processes that can take several hours in complex plants.

Reliability Analysis and Common Failure Modes

Deployed primarily in the late 1990s to early 2000s, many IS200ERIOH1AAA units are now operating well beyond their design life. Environmental stress and component aging are primary failure drivers.

Common failure modes include:

- Communication link IC degradation: Causes intermittent or complete loss of sync with the main controller, leading to “ERIO COMM FAULT” alarms.

- Power supply regulator failure: Results in unstable internal voltages, causing random resets or failure to boot.

- Electrolytic capacitor drying: Leads to ripple on DC rails, corrupting data or causing brownout conditions.

- Connector corrosion or pin fatigue: Especially in humid or corrosive environments, disrupting signal integrity to terminal boards.

Design weaknesses include reliance on through-hole components with finite lifespans and limited self-diagnostics for communication health. The module is also sensitive to ground loops and electrical noise from nearby high-power equipment.

Preventive maintenance recommendations:

- Inspect power supply voltage stability under load using an oscilloscope.

- Clean and reseat all connectors during scheduled outages.

- Monitor for recurring “COMM FAULT” events in historical logs—early sign of link instability.

- Ensure proper grounding of the remote I/O rack to minimize EMI interference.

GE IS200ERIOH1AAA

Lifecycle Status and Migration Strategy

GE has officially obsoleted the IS200ERIOH1AAA along with the entire Mark VI platform. No repair services or firmware updates are available, and technical support is limited to legacy documentation. Continued use carries escalating risk: verified spares are scarce, counterfeit parts circulate in gray markets, and integration knowledge is fading among service providers.

Short-term mitigation strategies include:

- Securing at least one tested, matched spare with compatible terminal board configuration.

- Documenting full I/O mapping and communication settings for rapid recovery.

- Isolating the remote rack from unnecessary electrical disturbances (e.g., VFDs, welding).

For long-term reliability, GE’s recommended path is migration to the Mark VIe or Mark VIe Evolution platform, which replaces the ERIO architecture with Ethernet-based I/O Packs featuring built-in redundancy, advanced diagnostics, and cybersecurity features. This transition requires:

- Rewiring or adapter solutions for existing field terminations

- Recompilation of control logic in ToolboxST

- Revalidation of protection and sequencing functions

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: