Description

Key Technical Specifications (For Spare Part Verification)

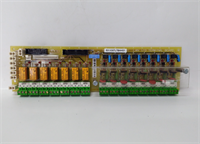

- Product Model: IS200ERDDH1ABA

- Manufacturer: GE Vernova

- System Family: Mark VIe Turbine Control System

- Module Type: Redundant Digital I/O Daughterboard (ERDD)

- Compatible Host Module: IS200EROCH1x series (EROC controller)

- I/O Configuration: Typically 16 digital inputs + 16 digital outputs (sinking/source configurable per channel)

- Voltage Rating: 24 V DC nominal (inputs), 24 V DC switched (outputs)

- Redundancy Architecture: Dual-channel, synchronized via backplane; supports 2oo2 or 1oo2 voting logic

- Mounting: Directly plugs into EROC base module; no separate terminal base required

- Diagnostic Capability: Channel-level LED indicators; fault reporting via IONet to Mark VIe controller

- Firmware Dependency: Must match host EROC firmware version and I/O configuration database

GE IS200ERDDH1ABA

System Role and Downtime Impact

The IS200ERDDH1ABA is deployed in critical turbine safety and sequencing circuits—such as emergency shutdown pushbuttons, lube oil pressure switches, or fuel valve position confirmations—where signal integrity and redundancy are mandated by API and IEC 61511 standards. It operates as a slave to the primary EROC module, extending discrete I/O capacity while maintaining full synchronization between redundant channels. If this daughterboard fails or loses synchronization, the Mark VIe system may force a turbine trip due to detected I/O mismatch or loss of voted signal validity. In combined-cycle or peaking plants, such an event can result in lost revenue exceeding $50,000 per hour, making this a high-consequence component despite its small physical size.

Reliability Analysis and Common Failure Modes

Although designed for industrial reliability, this module is vulnerable to long-term environmental stress and component obsolescence.

- Common Failure Modes:

- Optocoupler degradation in input channels, causing delayed signal recognition or false “on” states.

- Output transistor failure due to inductive kickback from unclamped solenoid loads, leading to open-circuit or shorted outputs.

- Connector pin corrosion or fretting at the EROC-daughterboard interface, resulting in intermittent communication or complete channel dropout.

- Design Weaknesses:

- Limited surge suppression on field wiring terminals; highly sensitive to voltage transients if external protection (e.g., TVS diodes) is not installed.

- No onboard battery or non-volatile memory—relies entirely on the host EROC for configuration, making standalone diagnostics difficult.

- Preventive Maintenance Recommendations:

- Inspect field wiring terminations annually for signs of arcing or overheating.

- Verify that all inductive loads (relays, solenoids) are equipped with flyback diodes or snubbers.

- Perform periodic redundancy sync tests during planned outages using ToolboxST diagnostic tools.

- Store spare units in static-shielded, climate-controlled packaging to prevent moisture ingress or ESD damage.

GE IS200ERDDH1ABA

Lifecycle Status and Migration Strategy

GE no longer manufactures the IS200ERDDH1ABA. The “ABA” suffix denotes a specific engineering change level tied to early Mark VIe deployments (circa 2010–2015), and newer ERDD revisions (e.g., IS200ERDDH2) are not mechanically or electrically backward-compatible without base module upgrades.

- Interim Solutions:

- Procure only from vendors who provide full functional test reports, including channel-by-channel continuity, timing response, and redundancy sync validation.

- Implement external signal monitoring (e.g., dry contact loggers) on critical trip paths to detect latent failures.

- Migration Path:

- GE’s long-term roadmap favors consolidation into the Mark VIeS platform with virtualized I/O and enhanced cybersecurity.

- For near-term sustainability, sites should:

- Audit all ERDD usage and consolidate low-utilization modules to reduce spare count.

- Where feasible, replace discrete I/O with smart field devices (e.g., PROFIBUS PA valves) to reduce hardwired points.

- Plan a phased migration to standard, currently supported I/O modules (e.g., IS200ERDDH2 with compatible EROC) during major outages.

- Until migration occurs, maintaining a minimum of two fully tested spares per turbine train is essential for operational resilience.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: