Description

Technical Specifications (For Spare Parts Verification)

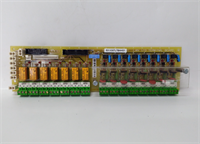

- Product Model: IS200EPSMG2AEC

- Manufacturer: GE Vernova

- System Family: Mark VI Turbine Control System

- Function: Chassis-mounted redundant power supply module (EPSM = Extended Power Supply Module)

- Input Voltage: 115/230 VAC, 50/60 Hz (auto-ranging)

- Output Voltages: +5 VDC (logic), +15 VDC, –15 VDC (for analog I/O)

- Output Current: Typically 10–15 A on +5 V rail; derated at high ambient temperatures

- Redundancy: Operates in parallel with a second EPSM; supports hot-swap and load-sharing

- Mounting: Slides into dedicated slot in Mark VI I/O or controller rack (e.g., IS200CHASx)

- Diagnostic Indicators: LEDs for AC OK, DC OK, FAULT, and REDUNDANCY STATUS

- Cooling: Convection-cooled; relies on cabinet airflow

- Connector Type: Backplane mating connector with locking mechanism; field wiring via terminal blocks for AC input and ground

GE IS200EPSMG2AEC

System Role and Downtime Impact

The IS200EPSMG2AEC is a foundational component of the Mark VI system’s power architecture. Installed in pairs for redundancy, these modules deliver clean, regulated power to the VME-based controller cards and remote I/O packs. In normal operation, if one unit fails, the other carries the full load without interruption. However, if both units degrade or a single-unit system fails, the entire rack loses power. This results in an immediate halt to control logic execution and I/O scanning. In turbine applications, this typically forces a protective shutdown due to loss of critical signals (e.g., speed, vibration, flame). Even in redundant configurations, repeated power stress can accelerate aging in the surviving unit, increasing the risk of cascading failure. Recovery requires replacement and verification of voltage stability—processes that demand system downtime and engineering support.

Reliability Analysis and Common Failure Modes

Deployed widely from the late 1990s through the 2000s, many IS200EPSMG2AEC units are now operating beyond their intended service life. Thermal stress and component wear are dominant failure mechanisms.

Common failure modes include:

- Electrolytic capacitor drying: Causes increased output ripple, voltage droop under load, or complete output collapse—especially on the +5 V rail.

- Fanless thermal runaway: In poorly ventilated cabinets, internal temperatures rise, degrading switching components and triggering over-temperature shutdowns.

- Input rectifier or MOV failure: Results from repeated voltage surges or lightning-induced transients, leading to blown fuses or short circuits.

- Backplane connector arcing: Corrosion or poor seating causes intermittent power delivery, manifesting as random module resets or “brownout” faults.

Design limitations include reliance on large electrolytic capacitors with finite lifespans (typically 7–10 years) and minimal active monitoring of individual rail health. The module also lacks modern protections like power factor correction or wide-range DC input.

Preventive maintenance recommendations:

- Measure output voltages under full load during PM windows; ripple should be < 100 mVpp on +5 V.

- Inspect for bulging capacitors or discoloration near heat-generating components.

- Ensure cabinet cooling maintains ambient temperature below 40°C at the module level.

- Verify secure seating in the chassis to prevent vibration-induced disconnection.

GE IS200EPSMG2AEC

Lifecycle Status and Migration Strategy

GE has formally discontinued the IS200EPSMG2AEC, with no official repair services or technical support available. Continuing to operate Mark VI systems dependent on this power supply exposes facilities to significant risk: genuine spares are increasingly scarce, pricing is volatile, and counterfeit or reconditioned units may lack reliability validation.

Short-term risk mitigation includes:

- Acquiring and functionally testing matched redundant pairs from certified suppliers.

- Implementing strict environmental controls (cooling, cleanliness) to extend remaining life.

- Monitoring output rails with permanent data loggers to detect early degradation.

For long-term sustainability, GE’s strategic path is migration to the Mark VIe or Mark VIe Evolution platform, which uses modern, modular, and cyber-secure power supplies with enhanced diagnostics, higher efficiency, and extended lifecycle commitments. Such a transition involves:

- Replacement of entire controller and I/O racks

- Rewiring or adapter solutions for field terminations

- Recompilation and validation of control logic

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: