Description

Key Technical Specifications (For Spare Parts Verification)

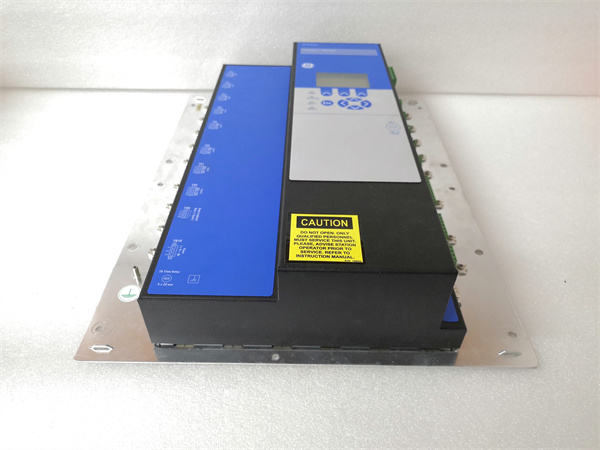

- Product Model: INTELLIX MO150

- Manufacturer: GE Multilin (General Electric)

- System Platform: Standalone motor protection relay for LV (≤690 V) induction motors

- Protection Functions: Thermal overload (IEC 60255 compliant), phase imbalance, phase reversal, under/over voltage, ground fault (residual current), stall, jam

- Current Inputs: 3-phase CT inputs (1 A or 5 A); built-in residual current measurement via internal summation or external core balance CT

- Control Outputs: 2 SPDT programmable relays (for trip and alarm), 1 solid-state output for direct starter control

- Communication: RS-485 port with Modbus RTU protocol (optional on some variants)

- Display: 4-digit LED display with navigation buttons for settings and diagnostics

- Mounting: Panel mount or DIN rail adapter (typically 35 mm)

- Operating Voltage: 24–240 VAC/VDC auxiliary supply

- Certifications: UL 508, CSA C22.2 No. 14, IEC 60255

System Role and Downtime Impact

The GE INTELLIX MO150 is typically installed in motor control centers (MCCs) as the primary protection and monitoring device for critical low-voltage motors—such as pumps, fans, and compressors—in industries like water treatment, mining, and manufacturing. It acts as both a protective relay and a basic motor management unit, interfacing directly with contactors or soft starters and often feeding status signals (e.g., “running,” “tripped”) into PLC or DCS systems via its dry contacts. If the MO150 fails—due to power supply degradation, relay contact welding, or internal logic corruption—it may either fail to trip during a fault (risking motor burnout) or nuisance-trip during normal operation (causing unplanned process interruption). In systems without redundant protection, a single MO150 failure can halt an entire production line or utility service, especially if the motor is part of a safety-critical or continuous-process loop.

Reliability Analysis and Common Failure Modes

Despite its rugged design, the INTELLIX MO150 is prone to age-related failures common in early-generation digital relays. The most frequent issues stem from electrolytic capacitors in the auxiliary power supply drying out over time, leading to erratic behavior or complete power loss. Relay contacts—particularly the trip output—can weld shut after repeated high-current switching, rendering the protection function inoperative. The internal current measurement circuitry is also sensitive to sustained overloads or CT open-circuit conditions, which may cause permanent calibration drift. A notable design weakness is the lack of non-volatile memory backup; firmware or settings can be lost during prolonged power interruptions if the internal energy buffer degrades. For preventive maintenance, technicians should annually inspect for bulging capacitors (visible through vent slots), verify relay coil resistance, test trip functionality using simulated faults, and confirm communication integrity if Modbus is used. Cleaning dust from heat-generating components and ensuring tight terminal connections significantly extend service life.

GE INTELLIX MO150

Lifecycle Status and Migration Strategy

GE has officially discontinued the INTELLIX MO150 series, with no direct replacement offered under the same product line. New units are unavailable through authorized channels, and remaining inventory exists only in the surplus market—often at inflated prices and with uncertain operational history. Continued reliance on this relay poses significant operational risk due to diminishing spares, lack of firmware updates, and absence of factory technical support. As an interim measure, facilities may consider board-level repair services or sourcing tested-used units with full functional verification. However, the recommended long-term strategy is migration to a modern equivalent. GE’s current successor platform is the Multilin™ 469 Motor Management Relay, which offers enhanced protection algorithms, color touchscreen interface, Ethernet connectivity (Modbus TCP, DNP3), and predictive diagnostics. Migration requires re-engineering the control wiring (due to different terminal layout), updating setpoints per new thermal models, and potentially reconfiguring PLC logic to accommodate new status signaling. For cost-sensitive applications, third-party alternatives such as the Eaton IQ150 or Siemens Sirius 3RM1 provide comparable functionality with easier integration paths. A phased replacement—prioritizing motors with highest criticality—is advised to manage capital expenditure while mitigating obsolescence risk.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: