Description

Key Technical Specifications (For Spare Part Verification)

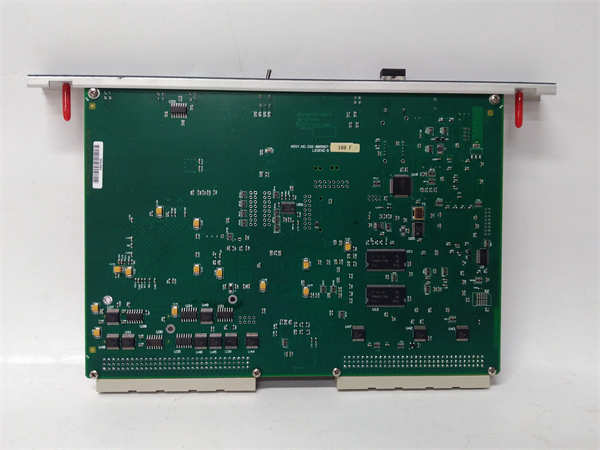

- Product Model: IC698RMX016

- Manufacturer: GE (Baker Hughes)

- System Platform: PACSystems RX3i

- Part Number: IC698RMX016 (must match exactly—different revisions may have compatibility issues)

- Function: Synchronizes program data between primary and secondary CPU modules, enabling seamless switchover in case of failure

- Installation Slot: Dedicated slot in RX3i chassis

- Communication Protocol: Proprietary GE protocol for real-time synchronization

- Redundancy Support: Yes—enables dual-redundant CPU configurations

- Diagnostic Indicators: LED status for health monitoring, sync status, and fault conditions

- Power: Supplied via backplane; no external power required

IC698RMX016 VMIVME-5567-100 GE

System Role and Downtime Impact

The IC698RMX016 module plays a crucial role in maintaining system availability by synchronizing the program data between two PACSystems RX3i CPU modules—one acting as the primary controller and the other as a hot standby. This setup ensures that if the primary CPU fails, the secondary CPU can immediately take over without interrupting operations.

If the IC698RMX016 fails, the following scenarios could occur:

- Loss of redundancy, leaving the system vulnerable to single-point failures;

- Inability to synchronize program updates between CPUs, potentially leading to discrepancies in control logic;

- Forced manual intervention to switch between CPUs, disrupting automatic failover mechanisms.

In industries where downtime can result in significant financial losses or safety hazards, such as oil and gas, water treatment, or power generation, the failure of this module can lead to severe operational disruptions.

Reliability Analysis and Common Failure Modes

Despite being designed for industrial reliability, the IC698RMX016 exhibits common aging issues typical of legacy electronics:

- Common Failure Modes:

- Capacitor leakage or failure, causing voltage instability and potential CPU lockups;

- Flash memory wear-out, leading to corruption of synchronized program data;

- Connector degradation, resulting in intermittent communication between CPUs;

- Firmware bugs that prevent proper synchronization during certain error conditions.

- Design Weaknesses:

- Limited self-diagnostic capabilities beyond basic LED indicators;

- Sensitivity to environmental factors like temperature fluctuations and electromagnetic interference;

- No built-in mechanism for firmware updates without physical access to the module.

- Preventive Maintenance Recommendations:

- Regularly inspect and clean connectors to ensure secure connections;

- Monitor cabinet temperatures to avoid overheating, which accelerates component aging;

- Perform periodic failover tests to verify redundancy functionality;

- Maintain detailed records of firmware versions and update procedures.

Lifecycle Status and Migration Strategy

- Official Status and Risks:

GE has transitioned to newer platforms, making IC698RMX016 less prominent in current offerings. Continued use carries risks such as:- Limited spare parts availability, increasing costs and lead times;

- Reduced technical support for troubleshooting and integration;

- Lack of modern cybersecurity features, exposing systems to vulnerabilities.

- Interim Mitigation Measures:

- Establish a strategic inventory of spares, tested and stored properly;

- Implement rigorous preventive maintenance schedules to extend module lifespan;

- Consider third-party repair services for minor faults to extend service life.

- Migration Path:

GE recommends migrating to newer PACSystems RX3i models with improved redundancy options, such as the RX3i CPE400/CPE410 series. These offer enhanced performance, security, and easier integration with modern industrial networks. The migration involves:- Upgrading controller hardware and reconfiguring redundancy settings;

- Revisiting control strategies to leverage new features;

- Potentially redesigning I/O layouts to accommodate updated module designs.

For sites unable to immediately upgrade, a phased approach targeting critical units first can mitigate immediate risks while planning for long-term modernization.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: