Description

Key Technical Specifications (For Spare Parts Verification)

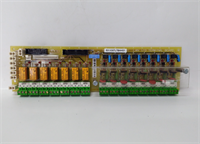

- Product Model: IC698RMX016-ED

- Manufacturer: GE Automation (now part of Emerson as of 2024)

- System Family: PACSystems RX3i

- Function: Redundant Memory Xchange (RMX) module for CPU synchronization

- Supported CPUs: IC695CPU315, IC695CPU320 (RX3i redundant pairs)

- Communication Interface: Dedicated high-speed serial link between RMX modules (via shielded cable, P/N IC698CBL001)

- Synchronization Rate: Real-time, deterministic update of I/O and program data

- Mounting: Backplane-mounted in RX3i redundancy chassis (IC698CHSxxx series)

- Diagnostic Indicators: LEDs for POWER, ACTIVE, FAULT, and LINK status

- Power Consumption: ~2.5 W

- Firmware Dependency: Must match firmware version of paired RX3i CPUs

- Physical Connector: 100-pin high-density backplane interface

System Role and Downtime Impact

The IC698RMX016-ED is a mission-critical component in GE PACSystems RX3i redundant control systems, commonly deployed in power generation, water/wastewater, and industrial facilities where continuous operation is mandated. It resides in both the primary and secondary controller chassis and maintains real-time synchronization of process data, I/O images, and program execution states. If one RMX module fails—due to internal electronics fault, firmware mismatch, or cable issue—the redundancy pair enters a degraded mode: the standby CPU cannot take over seamlessly during a primary CPU failure. This exposes the process to unplanned shutdowns. In worst-case scenarios (e.g., simultaneous RMX and CPU failure), the entire control system may halt, requiring manual restart and risking safety or environmental incidents.

Reliability Analysis and Common Failure Modes

Although engineered for industrial environments, the IC698RMX016-ED exhibits age-related vulnerabilities after 10–15 years of service. The most common failure mode is firmware corruption or version mismatch, often triggered by improper power cycling or failed CPU updates. This results in a solid FAULT LED and loss of synchronization. Second, high-density backplane connectors are prone to fretting corrosion or mechanical wear, leading to intermittent communication errors that destabilize the redundancy link. Third, internal FPGA or memory chips can degrade due to thermal stress, especially if installed in poorly ventilated cabinets, causing silent data corruption.

A key design limitation is its dependency on precise timing between paired modules—any latency introduced by aging components or marginal cabling can break the sync protocol. Additionally, the module provides no onboard logging; diagnostics rely solely on front-panel LEDs and CPU event logs, complicating root-cause analysis.

For preventive maintenance, verify RMX link status during routine checks—both units should show ACTIVE and stable LINK LEDs. Inspect the dedicated sync cable (IC698CBL001) for kinks or connector damage. Ensure firmware versions across CPUs and RMX modules are identical. During planned outages, reseat the module to clean backplane contacts. Monitor CPU event logs for “Redundancy Link Lost” or “Sync Error” messages as early warnings.

GE IC698RMX016-ED

Lifecycle Status and Migration Strategy

GE (now Emerson) has officially discontinued the PACSystems RX3i platform, including the IC698RMX016-ED, as part of its strategic shift toward the PACSystems FP and VersaMax NXT ecosystems. No new units are manufactured, and official repair or replacement services are no longer offered. Continued reliance on this module poses increasing operational risk due to shrinking spare inventory and lack of technical support.

As a short-term measure, secure at least one tested spare unit with verified synchronization functionality. Store it powered periodically to maintain capacitor health. Avoid mixing firmware revisions across redundant pairs.

For long-term sustainability, Emerson’s recommended migration path is to the PACSystems FP family, specifically using redundant FP CPUs (e.g., IC750FPC0020) with built-in Ethernet-based redundancy (no separate RMX module required). This transition involves:

- Replacing RX3i chassis, CPUs, and I/O modules with FP equivalents

- Rewiring I/O (FP uses different terminal blocks and backplane)

- Migrating application logic via Proficy Machine Edition (though full revalidation is typically needed)

- Retraining maintenance staff on the new platform

Given the complexity, many users adopt a “life extension” strategy: enhance monitoring of existing RMX links, maintain rigorous spares management, and plan migration during major plant turnarounds. Early consultation with Emerson-certified integrators is strongly advised to evaluate technical feasibility and total cost of ownership over the next 5–10 years.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: