Description

Key Technical Specifications (For Spare Part Verification)

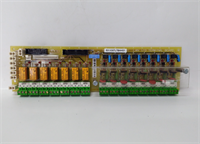

- Product Model: IC697CPX928-FE

- Manufacturer: GE Fanuc Automation (Emerson)

- System Platform: Series 90-70 PLC

- CPU Type: 32-bit RISC processor

- Memory: 2 MB user memory (expandable via PROM modules)

- Execution Speed: 0.4 µs per Boolean instruction

- Redundancy: Supports hot-standby configuration with IC697CHS750 or IC697CHS790 redundancy modules

- Communication Ports: 1 × RS-485 (for SNPX), 1 × Ethernet (10BASE-T, for TCP/IP and SRTP)

- Backplane Compatibility: Requires 5-slot or larger Series 90-70 baseplate (e.g., IC697BEM731)

- Programming Software: Proficy Logic Developer PLC (formerly VersaPro)

- Firmware Version: Must match existing system (typically v3.x or v4.x); mismatch can cause boot failure

- Battery Backup: Requires external lithium battery module (IC697ACC701) for RAM retention

-

GE IC697CPX928-FE

System Role and Downtime Impact

The IC697CPX928-FE serves as the central brain in legacy GE Series 90-70 control systems, commonly deployed in continuous-process industries where unplanned downtime carries severe operational and safety consequences. In redundant configurations, it operates in lockstep with a standby unit to ensure seamless failover during hardware faults. If this CPU fails—due to memory corruption, firmware crash, or power-related damage—and no tested spare is available, the entire control system halts. Unlike modular modern platforms, the 90-70 architecture lacks virtualization or cloud-based fallback options. Recovery typically requires physical replacement and re-synchronization, leading to extended plant stoppages that can last hours or days, depending on spare parts logistics.

Reliability Analysis and Common Failure Modes

Although engineered for industrial environments, the IC697CPX928-FE is now well beyond its intended service life (typically 10–15 years). The most prevalent failure modes include CMOS memory loss due to battery depletion, electrolytic capacitor degradation on internal power regulation circuits, and corrosion on backplane connectors from thermal cycling. The onboard flash PROMs may also suffer bit rot over time, causing unpredictable boot behavior or program corruption.

A critical design vulnerability is its dependence on the external battery module (IC697ACC701) for RAM retention during power cycles. If the battery voltage drops below 2.8 V—even briefly—the application logic and configuration data can be lost, requiring full reload from backup media (often outdated or unreadable).

Preventive maintenance recommendations include:

- Replacing the backup battery every 2–3 years, regardless of voltage reading

- Performing annual checksum verification of the loaded program

- Cleaning and reseating the module in its chassis to prevent intermittent contact

- Maintaining a powered “warm spare” unit to condition internal components

- Archiving logic in multiple formats (source + binary) and verifying readability on legacy PCs

-

GE IC697CPX928-FE

Lifecycle Status and Migration Strategy

Emerson discontinued the entire Series 90-70 line years ago, with final support ending in the late 2010s. No direct replacement exists under the GE or Emerson brand. Continuing to operate systems with the IC697CPX928-FE entails escalating risks: spare units are scarce, prices exceed original cost by 3–5x, and compatibility with modern engineering workstations is increasingly tenuous due to OS and driver obsolescence.

Short-term mitigation includes sourcing refurbished units from specialized third-party vendors and implementing rigorous spares management (e.g., keeping two verified spares on-site). Some facilities employ board-level repair services to replace capacitors or reprogram PROMs, though success rates vary.

For long-term sustainability, migration to a modern PAC platform is essential. Emerson recommends transitioning to the PACSystems RX3i or RXi2 series, which offer functional equivalence, higher performance, and native support for OPC UA, PROFINET, and cybersecurity standards. This migration requires re-engineering I/O wiring (via adapter plates in some cases), recompiling logic in Proficy Machine Edition, and updating HMI/SCADA interfaces. While capital-intensive, it eliminates obsolescence exposure and restores access to technical support, security patches, and remote diagnostics capabilities.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: